Hydrating case for moisture-containing lens and hydrating method using it

a technology of hydrating case and contact lens, which is applied in the direction of transportation and packaging, packaging goods types, other domestic objects, etc., can solve the problems of poor efficiency in elution of unreacted monomers, uneven water absorption and swelling, etc., and achieve the elimination of dust or contamination, the effect of effective extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to illustrate the invention more concretely, the embodiments of the invention are described in detail hereinbelow, making reference to the accompanying drawings.

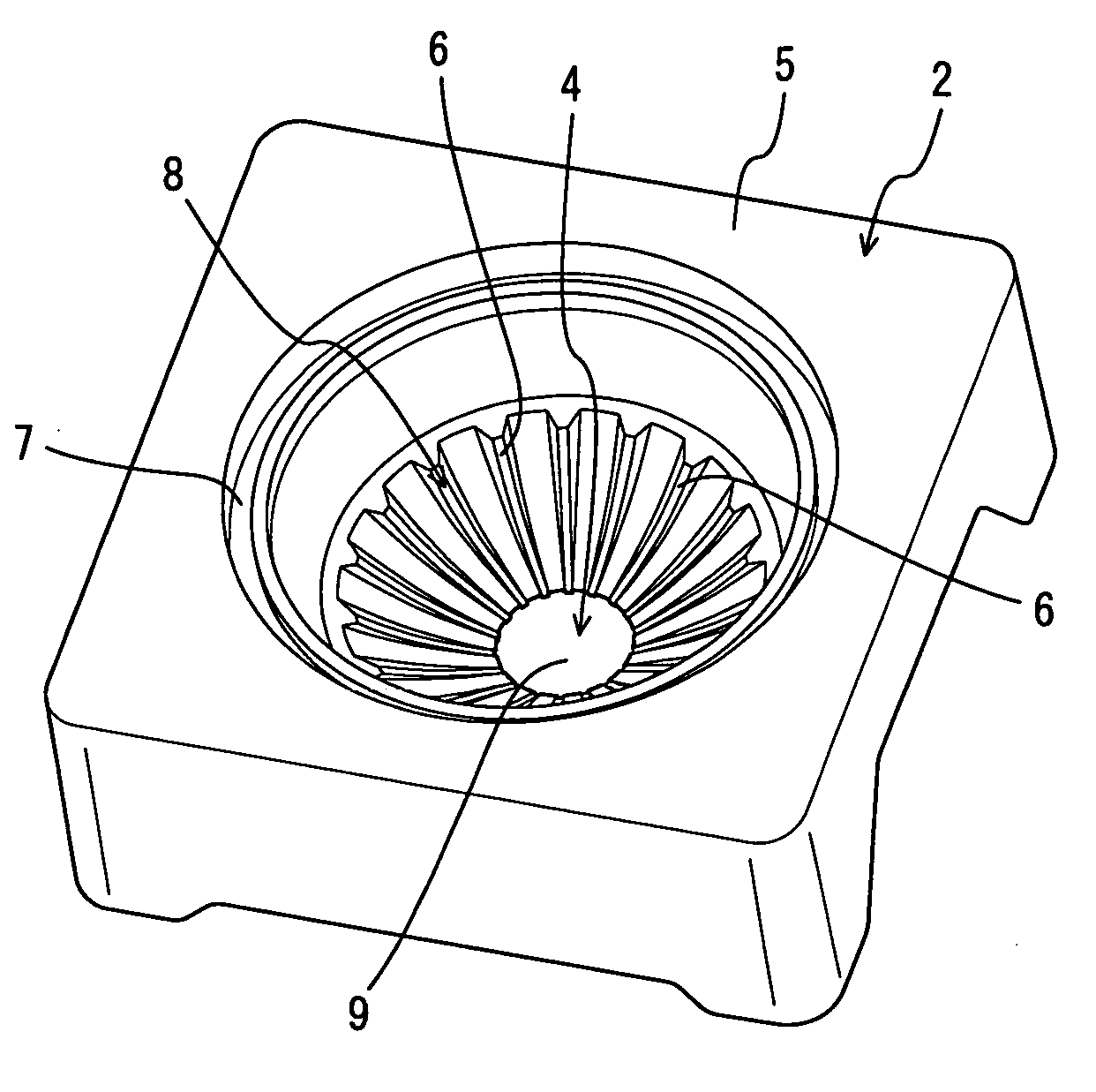

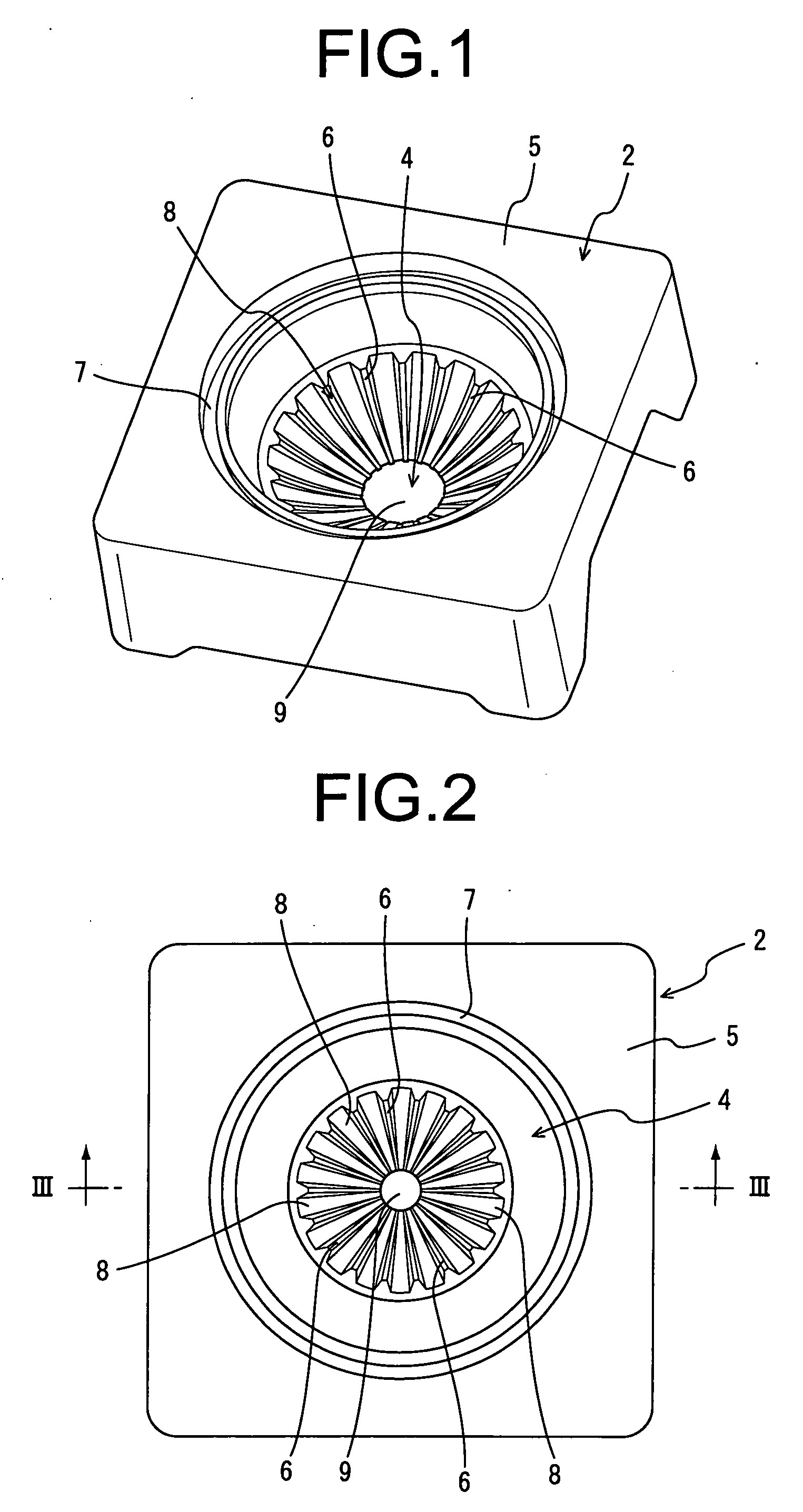

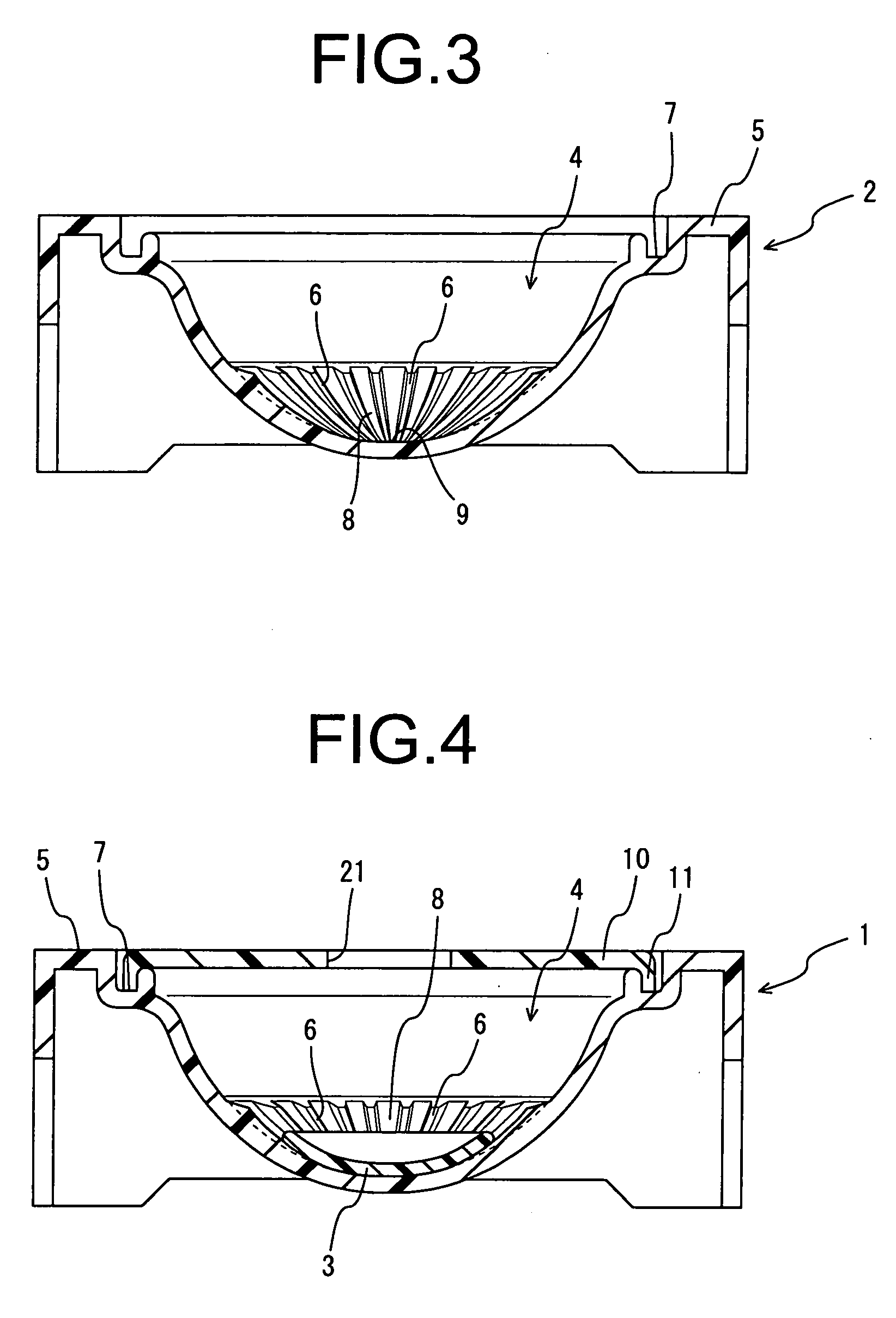

[0080] A treatment case 2 for a moisture-containing contact lens is shown in FIG. 1 to FIG. 3 by way of a first embodiment of the invention. This case 2 has a recess 4 as a containment recess for containing the moisture-containing contact lens (3). In the description hereinbelow, as a general rule, the vertical direction in FIG. 3 shall be deemed the vertical direction.

[0081] More specifically, the case 2 structure has a rectangular top panel 5, and four leg portions extending integrally in the thickness direction of the top panel 5, i.e. downward, from the four corners of the top panel 5. In this embodiment, the top panel 5 has a square shape overall. In the generally central portion of the top panel 5 is formed a recess 4 that opens in the other the thickness direction of the top panel 5, i.e. upward. Thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| groove width | aaaaa | aaaaa |

| groove width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com