Method of doping organic semiconductors with quinone derivatives and 1, 3, 2 - dioxaborine derivatives

a technology of organic semiconductors and dioxaborine, which is applied in the direction of non-metal conductors, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of high control and regulation expenses, inability to precisely control the manufacturing process in large technical production plants or those on a technical scale, and disadvantages of compounds previously investigated, so as to facilitate the processing of organic semiconductors and reduce volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

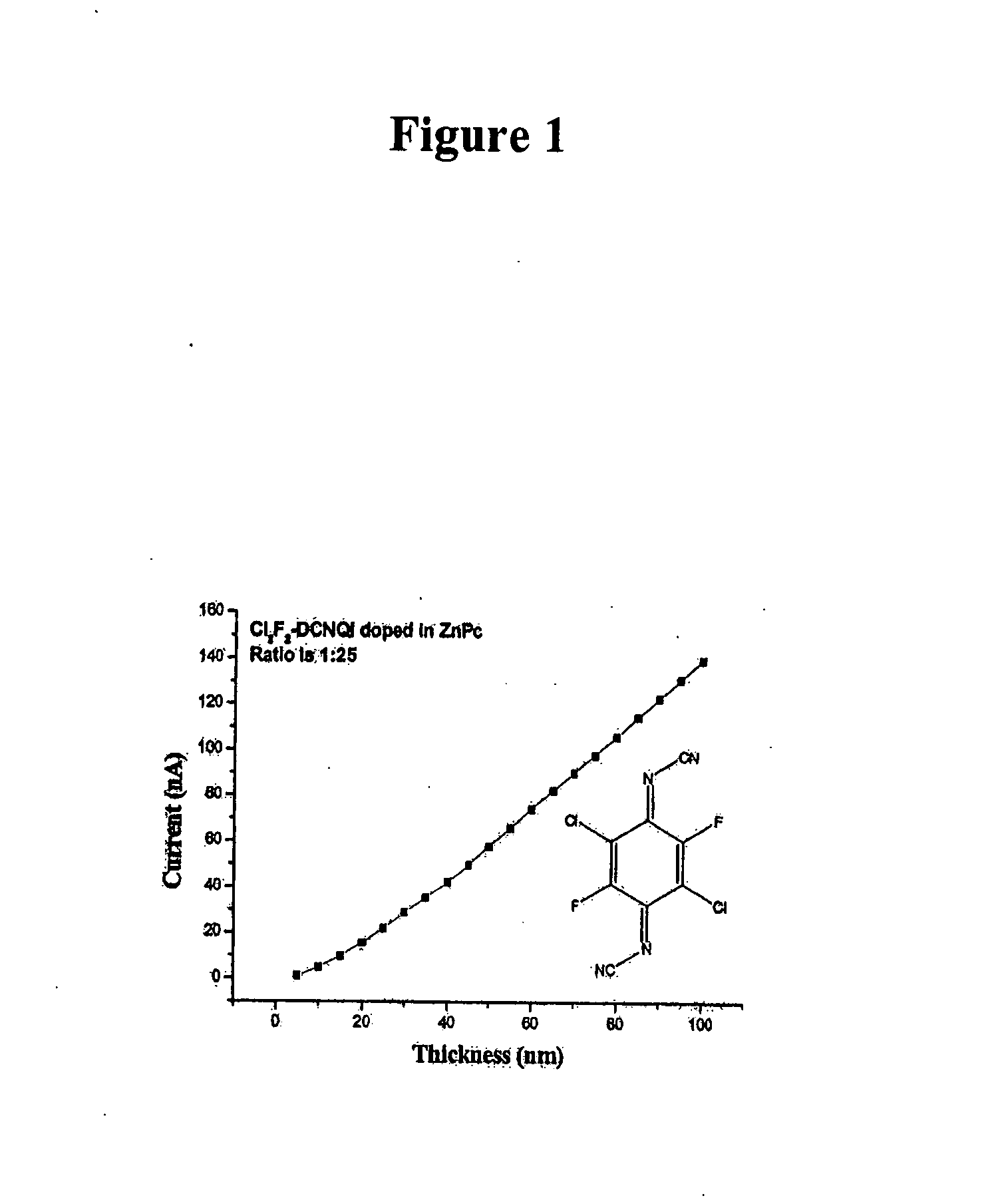

[0389] Doping of ZnPc with N,N′-dicyano-2,3,5,6-tetrafluoro-1,4-quinonediimine (F4DCNQI)

[0390] The evaporation temperature T(evap.) is 85° C. The two components matrix and dopant were deposited from vapor under vacuum in a ratio of 50:1. Here the conductivity is 2.4×10−2 s / cm. Results are shown in FIG. 1 and Table 1 below.

TABLE 1Layer ThicknessCurrent(nm)(nA)569.0510400.915762.5201147251503.2301874.4352233.4402618453001.5503427

example 2

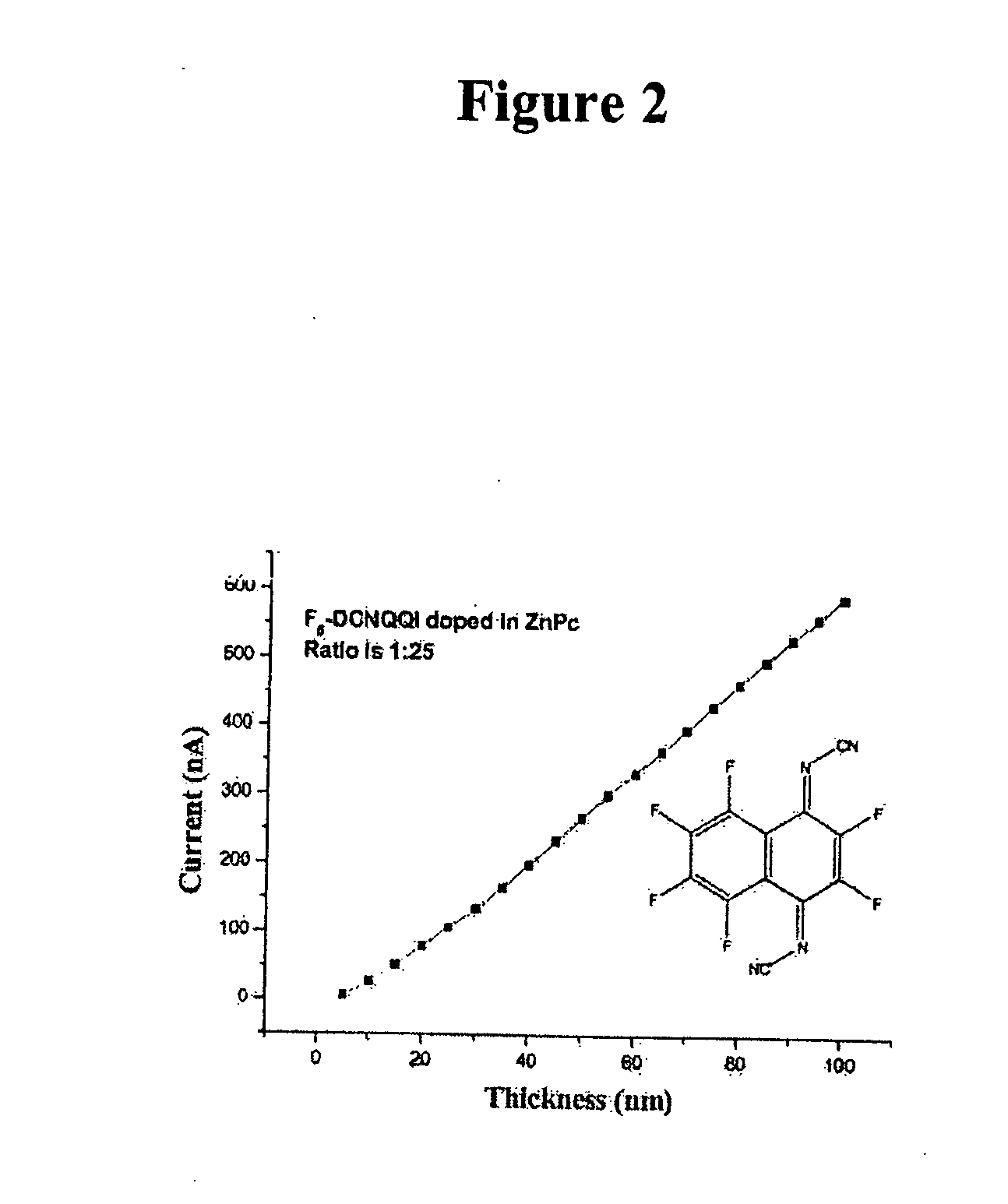

[0391] Doping of ZnPc with N,N′-dicyan-2,5-dichloro-1,4-quinonediimine (C12DCNQI) the evaporation temperature T(evap.) is 114° C. The ratio of the two compounds in the vapor-deposited layer is 1:50 in favor of the matrix. A conductivity of 1.0×10−2 s / cm was measured in the layer. Results are shown in FIG. 2 and Table 2 below.

TABLE 2Layer ThicknessCurrent(nm)(nA)542.6610179.415334.22048425635.53078635946401091.5451253501409.8

example 3

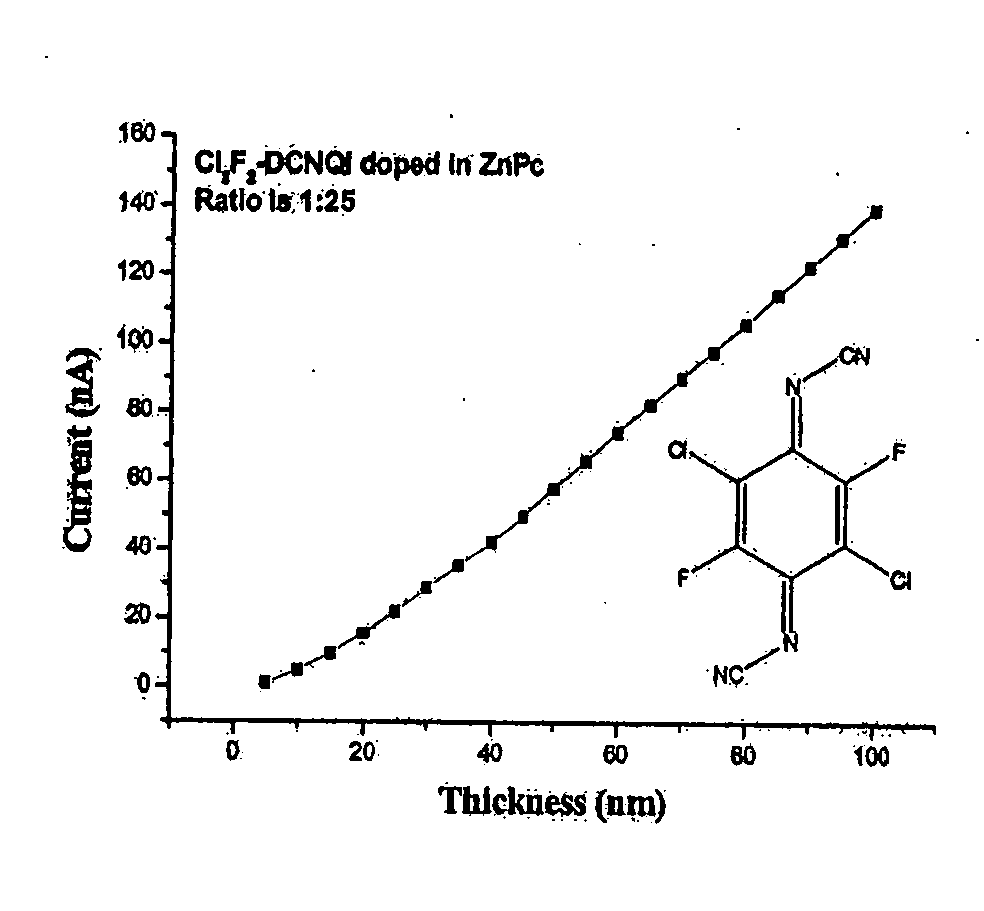

[0392] Doping of ZnPc with N,N′-dicyano-2,5-dichloro-3,6-difluoro-1,4-quinonediimine (C12F2DCNQI)

[0393] The evaporation temperature T(evap.) is 118° C. The layer was vapor-deposited under vacuum at the ratio of 1:25 (dopant matrix). A conductivity of 4.9×10−4 s / cm was measured there. Results are shown in FIG. 3 and Table 3 below.

TABLE 3LayerthicknessCurrent(nm)(nA)51.1648104.7852159.72112015.5822521.9853028.8663535.454042.2494549.7475057.865566.0126074.3356582.4497090.2517597.96880106.1485114.5890122.8495131.1100139.59

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com