Pressure relief system for paint circulation applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

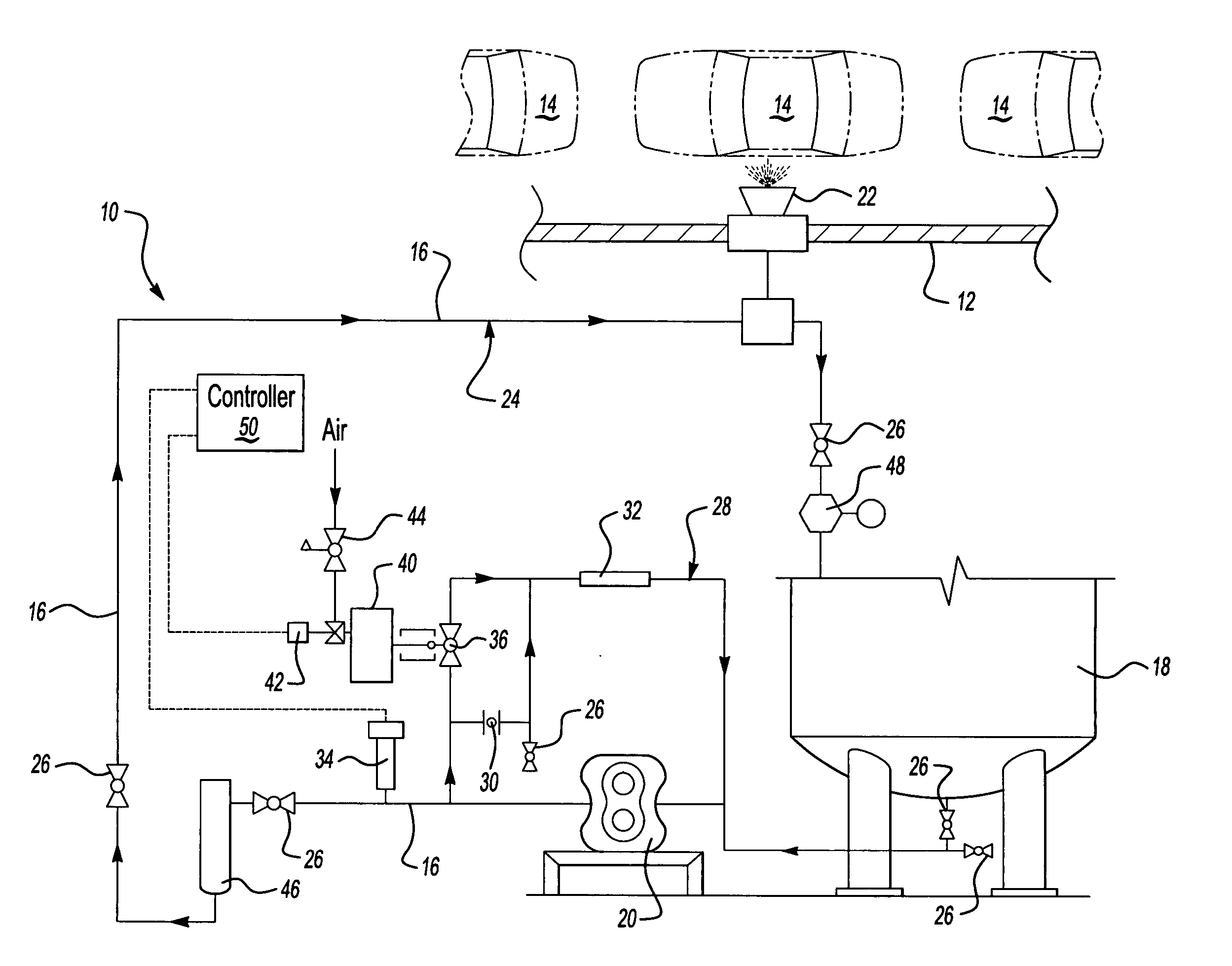

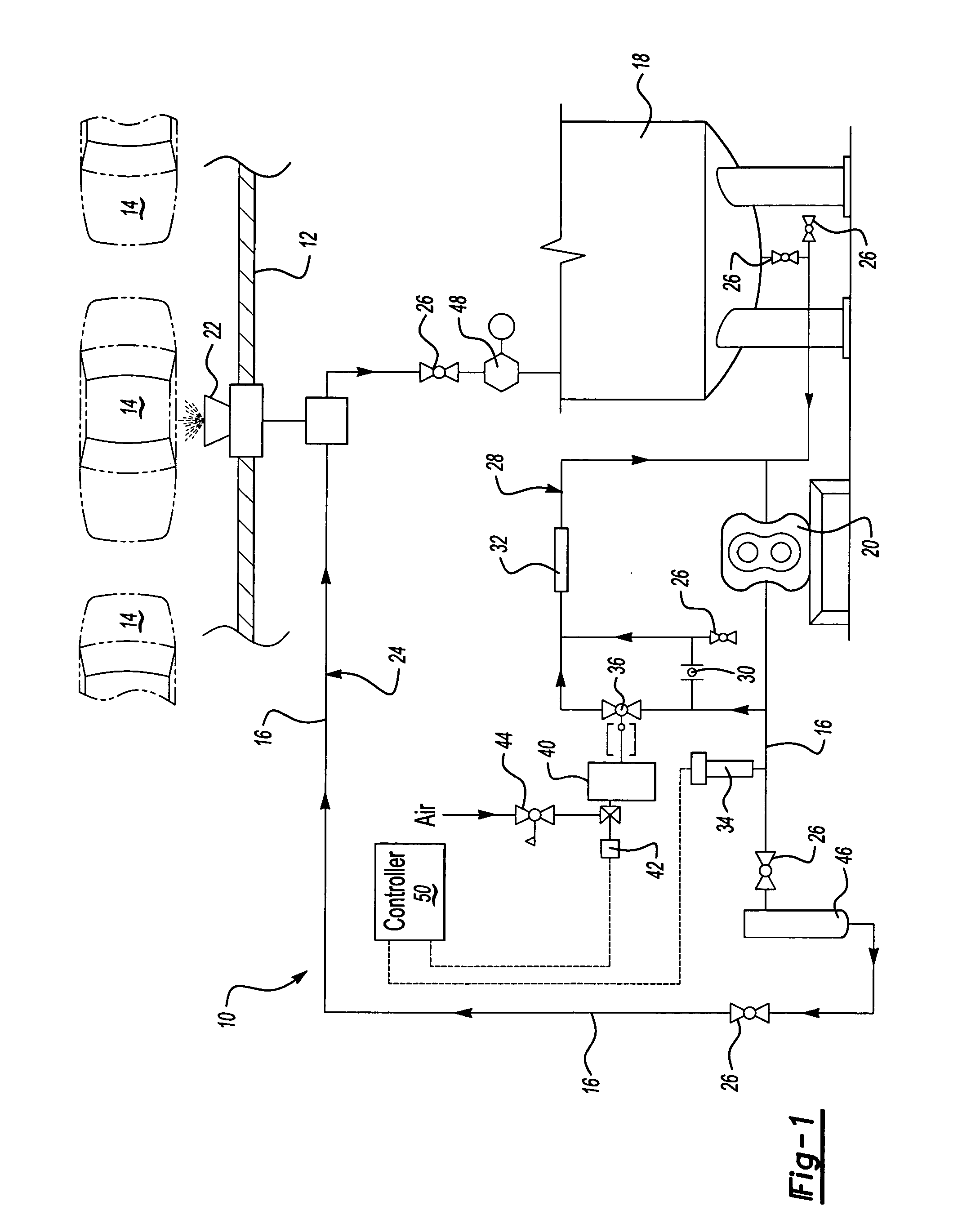

[0012] Referring to FIG. 1, wherein like numerals indicate like or corresponding parts, an inventive closed loop paint circulation system is generally shown at 10. The paint circulation system 10 supplies paint to at least one paint booth 12 where the paint is applied to a product, such as, for example, a vehicle body 14. In a typical automobile assembly plant paint is maintained in constant circulation through long circulation line 16 stretching between a paint reservoir 18 and one or more paint spray booths 12 by a pump 20. The vehicle body 14 is transported through the paint spray booth 12 by conveying equipment (not shown) where the paint is applied to the vehicle body 14 and subsequently cured in a paint oven (not shown) as is known to those skilled in the art. The paint may be applied by human operators or mechanically by automated equipment 22 such as rotary atomizers. The equipment 22 is generally disposed inside the walls of the paint booth 12 and is robotically operated, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com