Alternating-current dynamoelectric machine

a dynamoelectric machine and alternating current technology, applied in the direction of engine starters, magnetic circuit rotating parts, magnetic circuit shape/form/construction, etc., can solve the problems of increasing costs proportionally, poor durability, and affecting the performance of the engine, so as to reduce the volume of permanent magnets, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

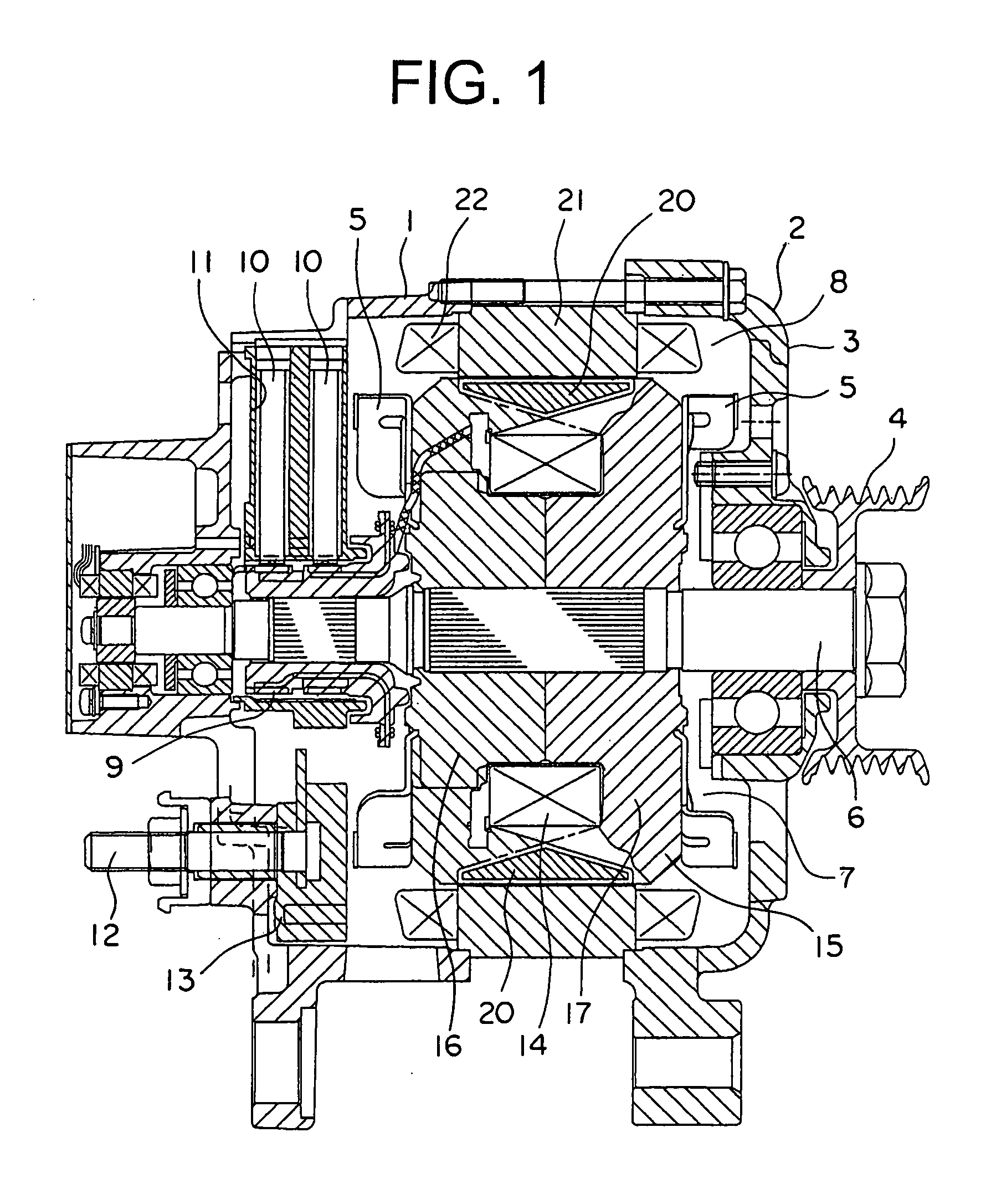

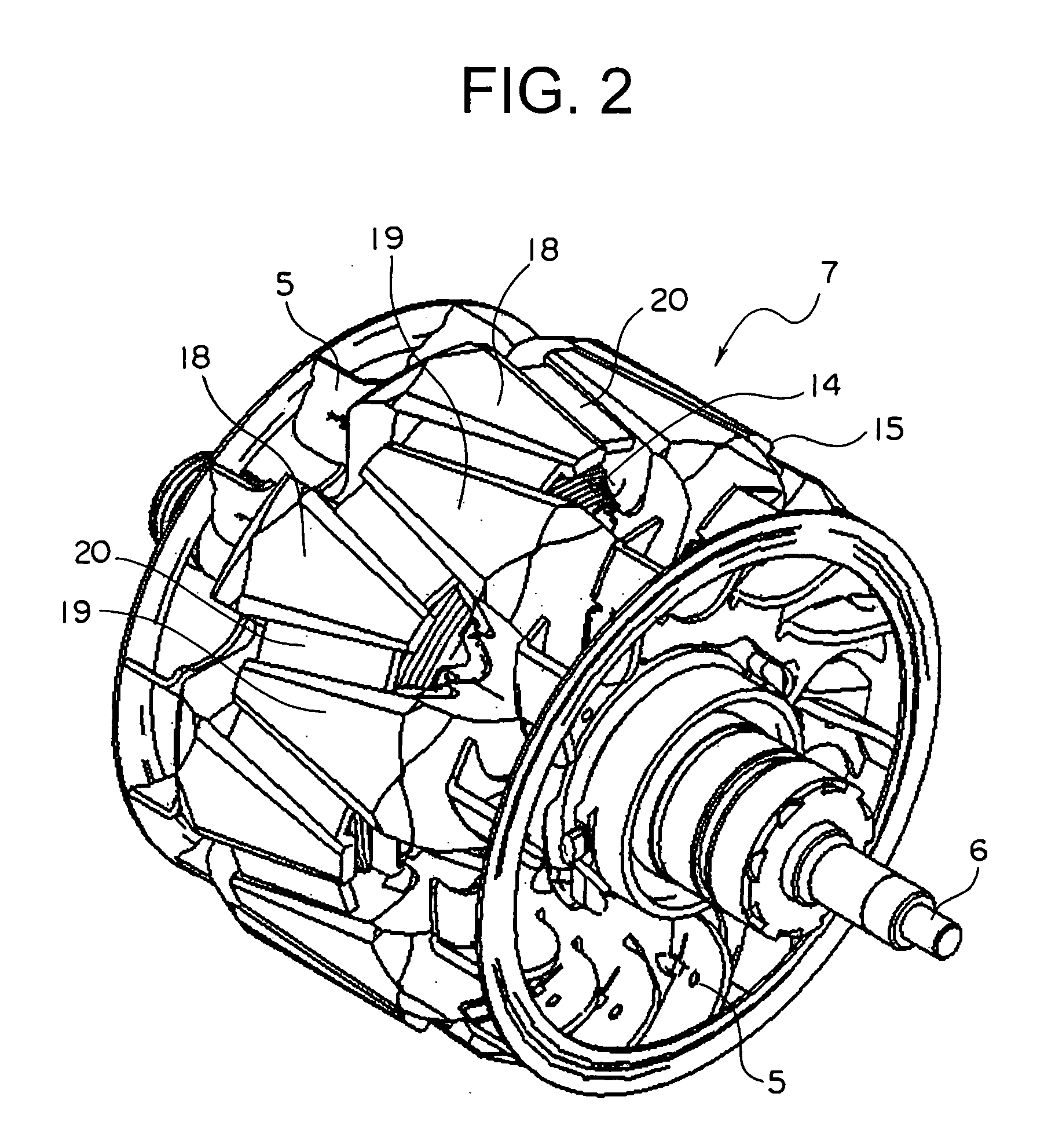

[0037]FIG. 1 is a cross section showing an automotive alternating-current generator-motor according to Embodiment 1 of the present invention, and FIG. 2 is a perspective of a rotor from FIG. 1.

[0038] This automotive alternating-current generator-motor (hereinafter “generator-motor”), which constitutes a dynamoelectric machine, includes: a case 3 constituted by a front bracket 1 and a rear bracket 2 made of aluminum; a shaft 6 disposed inside the case 3, a pulley 4 being secured to a first end portion of the shaft 6; a Lundell-type rotor 7 secured to the shaft 6; fans 5 secured to two end surfaces of the rotor 7; a stator 8 secured to an inner wall surface of the case 3; slip rings 9 secured to a second end portion of the shaft 6 for supplying electric current to the rotor 7; a pair of brushes 10 sliding on the slip rings 9; a brush holder 11 housing the brushes 10; a terminal block 12 disposed on the front bracket 1 for connecting to an inverter circuit (not shown); and a circuit b...

embodiment 2

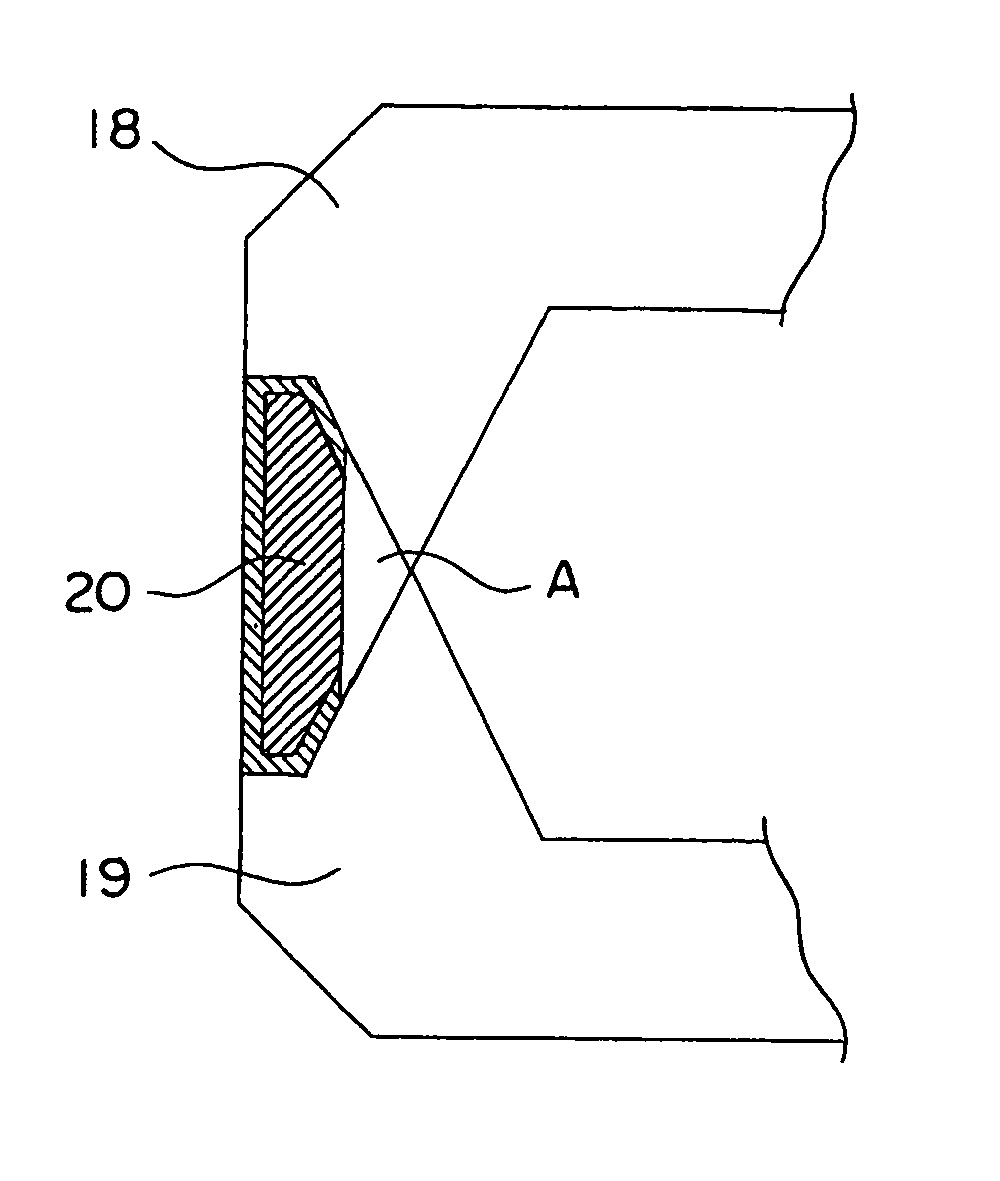

[0064] If the required starting torque is still not achieved by mounting the permanent magnets 20 within the plane of projection A of the adjacent claw-shaped magnetic poles 18 and 19, it may be necessary to increase the volume of the permanent magnets 20 further. Here, one simple way to increase the volume of the permanent magnets 20 is to increase the thickness of the permanent magnets 20 of the rotor 7 (dimensions in the direction of rotation of the rotor 7).

[0065] However, since there is only limited space between the adjacent claw-shaped magnetic poles 18 and 19, there is a limit to how much the thickness of the permanent magnets 20 can be increased.

[0066] Consequently, the necessity may arise to mount the permanent magnets 20 in portions protruding from within the plane of projection.

[0067] FIGS. 10 to 13 show examples in which a portion of the permanent magnets 20 protrudes out of the region of the plane of projection A, but the way in which each protrudes is different.

[0...

embodiment 3

[0072]FIG. 15 is a magnetic pole cross section when claw-shaped magnetic poles 18 and 19 are not parallel and when they are parallel, FIG. 16 is a perspective showing a case when the claw-shaped magnetic poles 18 and 19 are parallel, and FIG. 17 is a partial plan when permanent magnets 20 are mounted between the claw-shaped magnetic poles 18 and 19 shown in FIG. 15.

[0073]FIG. 18 shows magnetic leakage flux density when the claw-shaped magnetic poles 18 and 19 are not parallel and when they are parallel. When the claw-shaped magnetic poles 18 and 19 are not parallel, the total amount of magnetic flux (surface area in FIG. 18) is increased compared to when they are parallel, since the magnetic leakage flux φ where the distance between the claw-shaped magnetic poles 18 and 19 is narrow (on the radially-outer side of the rotor 7) increases in inverse proportion to the distance between the claw-shaped magnetic poles 18 and 19, but the amount of magnetic leakage flux can be reduced by ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com