Semiconductor device

a technology of semiconductor devices and semiconductors, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of complex prioritizing soldering parts, deteriorating device radiation characteristics, and cracks in the soldering portion, so as to reduce the deterioration of heat dissipation characteristics and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

modified embodiment

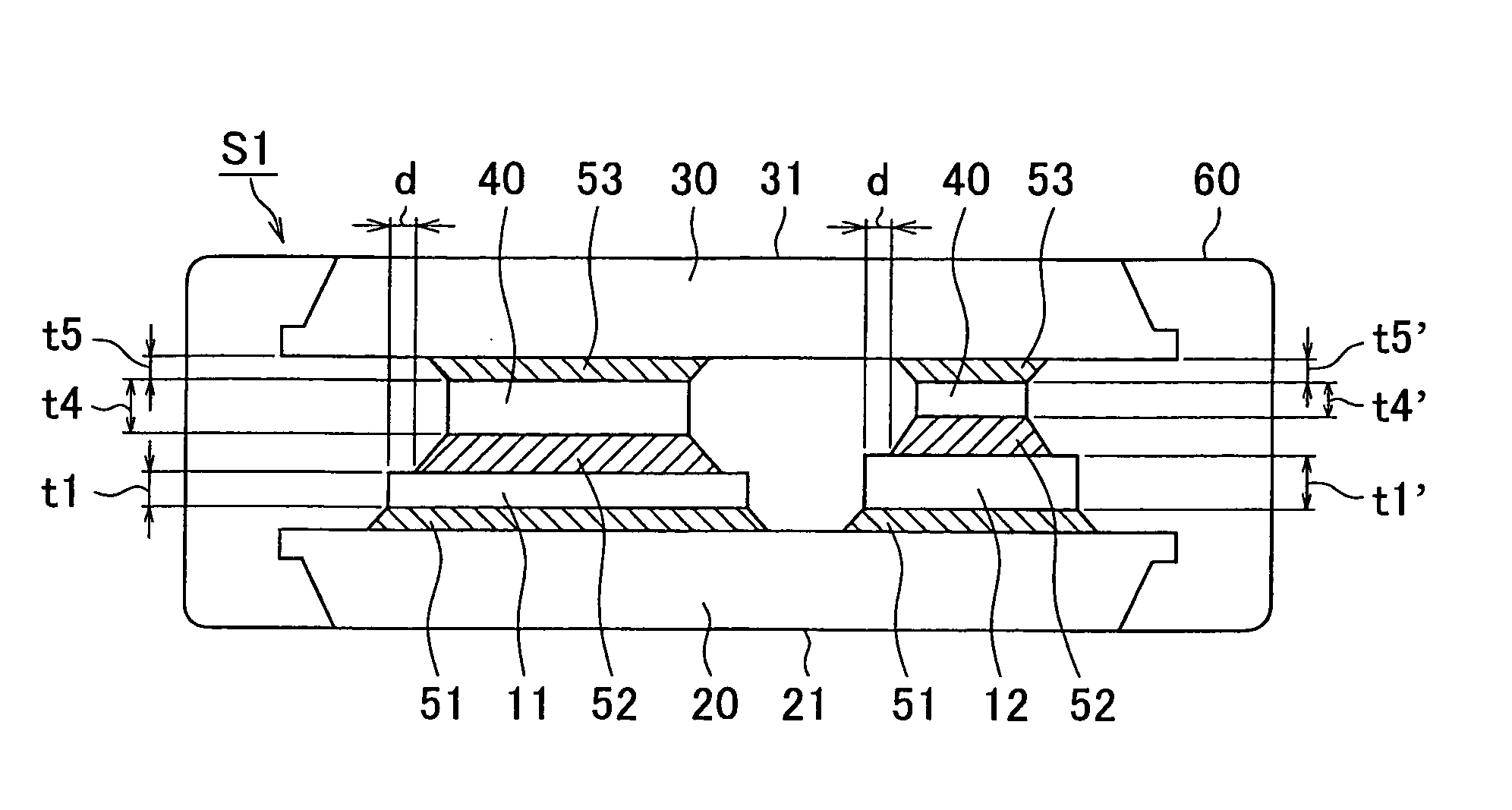

[0141] In the example shown in FIG. 1, the parallel arrangement of the radiating surfaces 21, 31 is achieved by changing the thickness t4, t4′ of each of the heat sink blocks 40, or the thickness t5, t5′ of each of the third solder portions 53 on each of the semiconductor chips 11, 12, when the thickness t1, t1′ of each of the plural semiconductor chips 11, 12 are different.

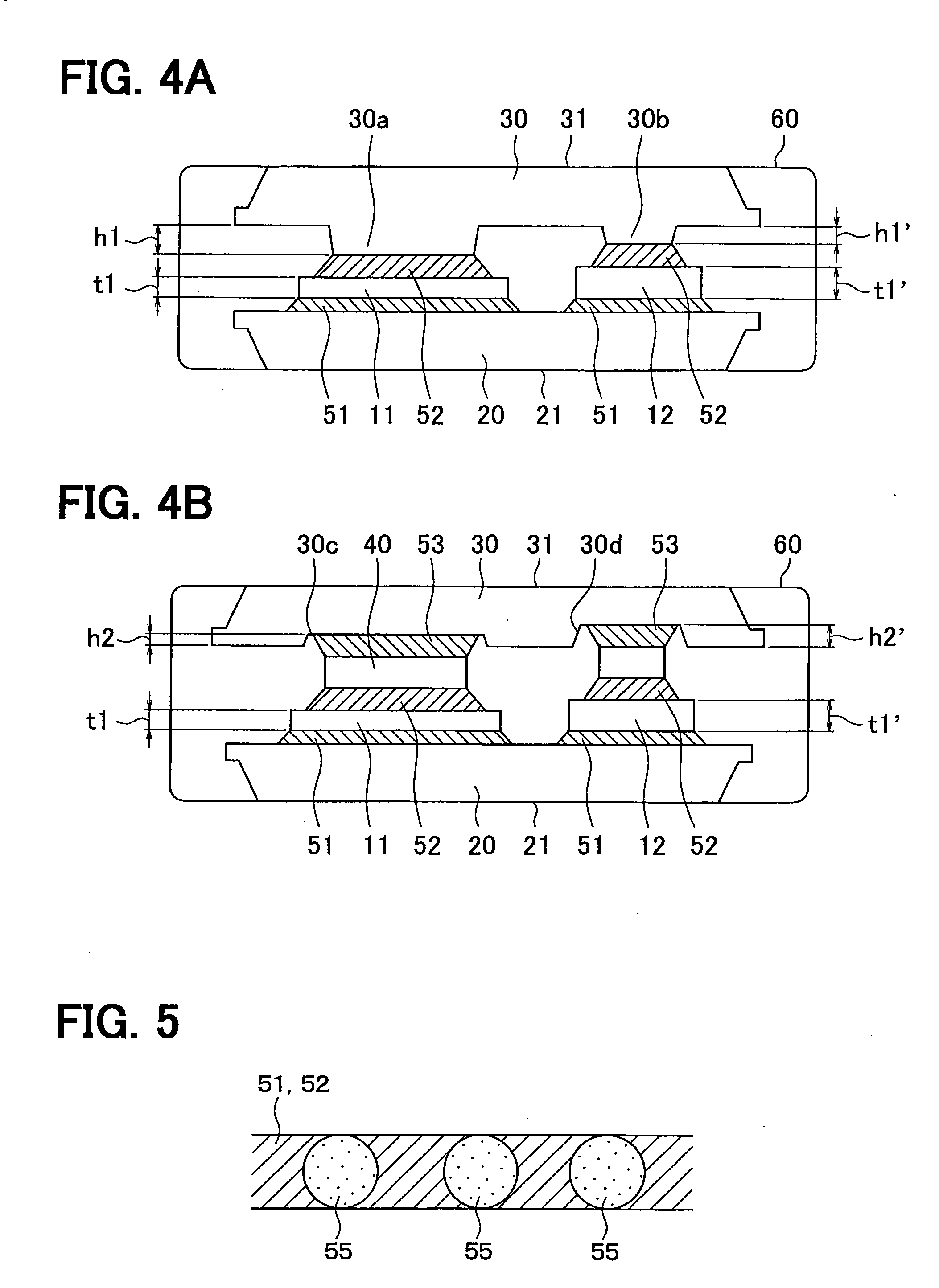

[0142] In this modified embodiment, a different method is devised to achieve the parallel arrangement. FIG. 4A and FIG. 4B show schematic cross sections of the first modified embodiment and the second modified embodiment respectively.

[0143] The semiconductor devices in FIG. 4A and FIG. 4B differ in the method to achieve the parallel arrangement of the radiating surfaces 21, 31, with the same structure in the remaining portion.

[0144] In the semiconductor devices in FIG. 4A and FIG. 4B, plural semiconductor chips 11, 12 of different thickness t1, t1′ are disposed on the same plane between the single lower heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com