Core gluing device for a rewinding machine and related method

a rewinding machine and core gluing technology, which is applied in the direction of fluid heaters, lighting and heating apparatus, heating types, etc., can solve the problems of frequent maintenance, limited production capacity of the rewinding machine, and inability to adjust the amount of glue applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

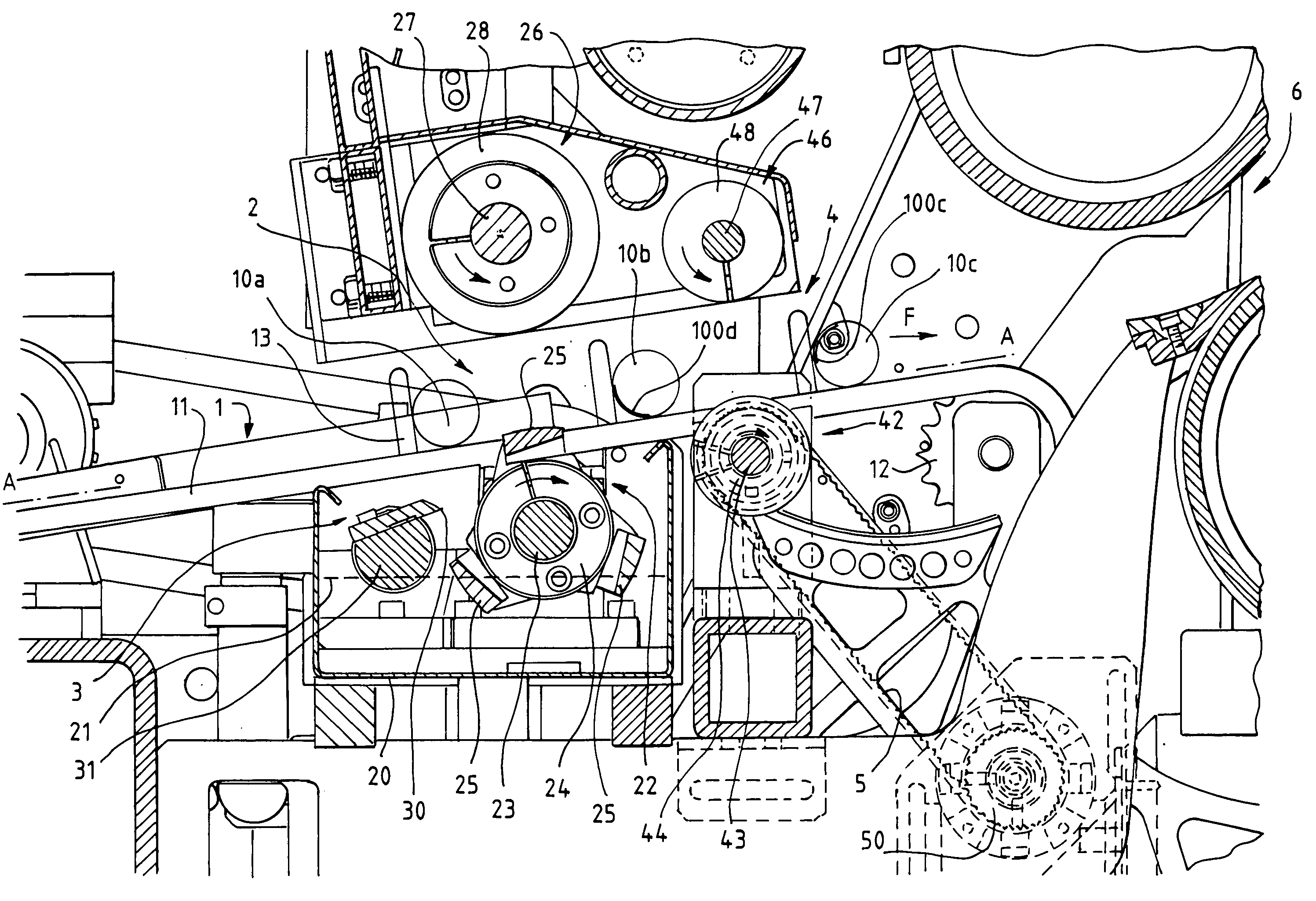

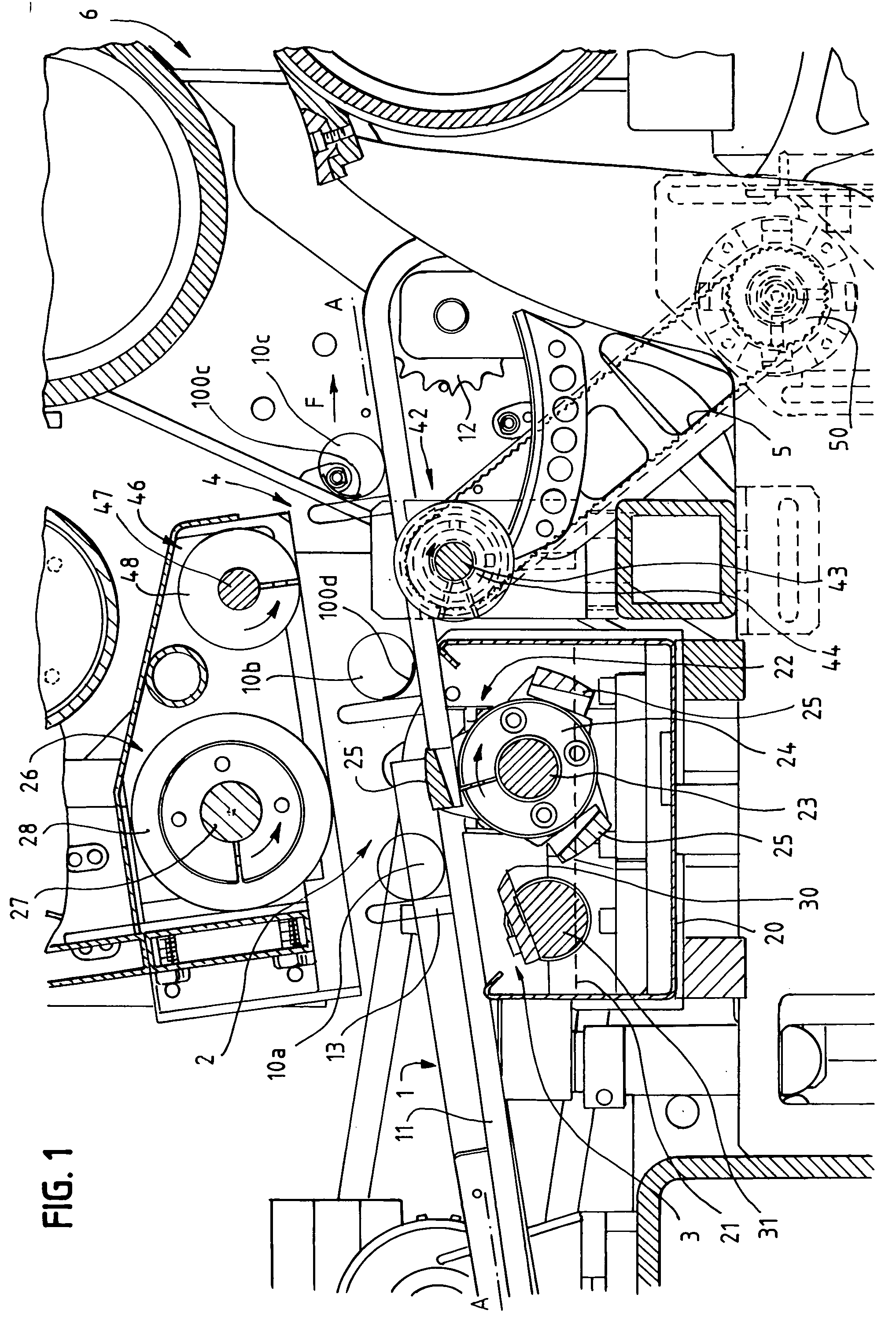

[0027] The gluing device according to the invention comprises a conveyor 1 designed to convey a plurality of tubular cores (10a, 10b, 10c), a glue application unit 2 designed to apply the glue on the outer surface of said cores (10a, 10b, 10c), and positioning devices 4 designed to position the cores (10a, 10b, 10c) in a suitable position for their insertion between the winding rollers of a winding unit 6 (illustrated partially) forming part of the rewinding machine.

[0028] The conveyor 1 comprises a conveying surface A-A defined by the arrangement of conveying chains 11, sloping slightly upwards, on which the cores (10a, 10b, 10c) are conveyed in a feed direction indicated by the arrow F. In the solution shown, the conveyor 1 comprises one or more chains 11 driven by motorized crown gears 12 in order to feed the cores forward.

[0029] The conveyor chains 11 are fitted with a plurality of pusher devices 13 in the form of plates that protrude upwards, substantially square to the conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com