Magnetic recording head, magnetic reproducing head, magnetic head, tape drive and disk drive

a technology of reproducing head and magnetic head, which is applied in the direction of recording information storage, track selection/addressing details, instruments, etc., can solve the problems of limiting the positioning accuracy of each masking in the lamination, the difference between the top and bottom magnetic head elements in the width direction of the head, and the significant difference between the top and bottom magnetic head elements in the lamination direction, so as to simplify the manufacturing process. , the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

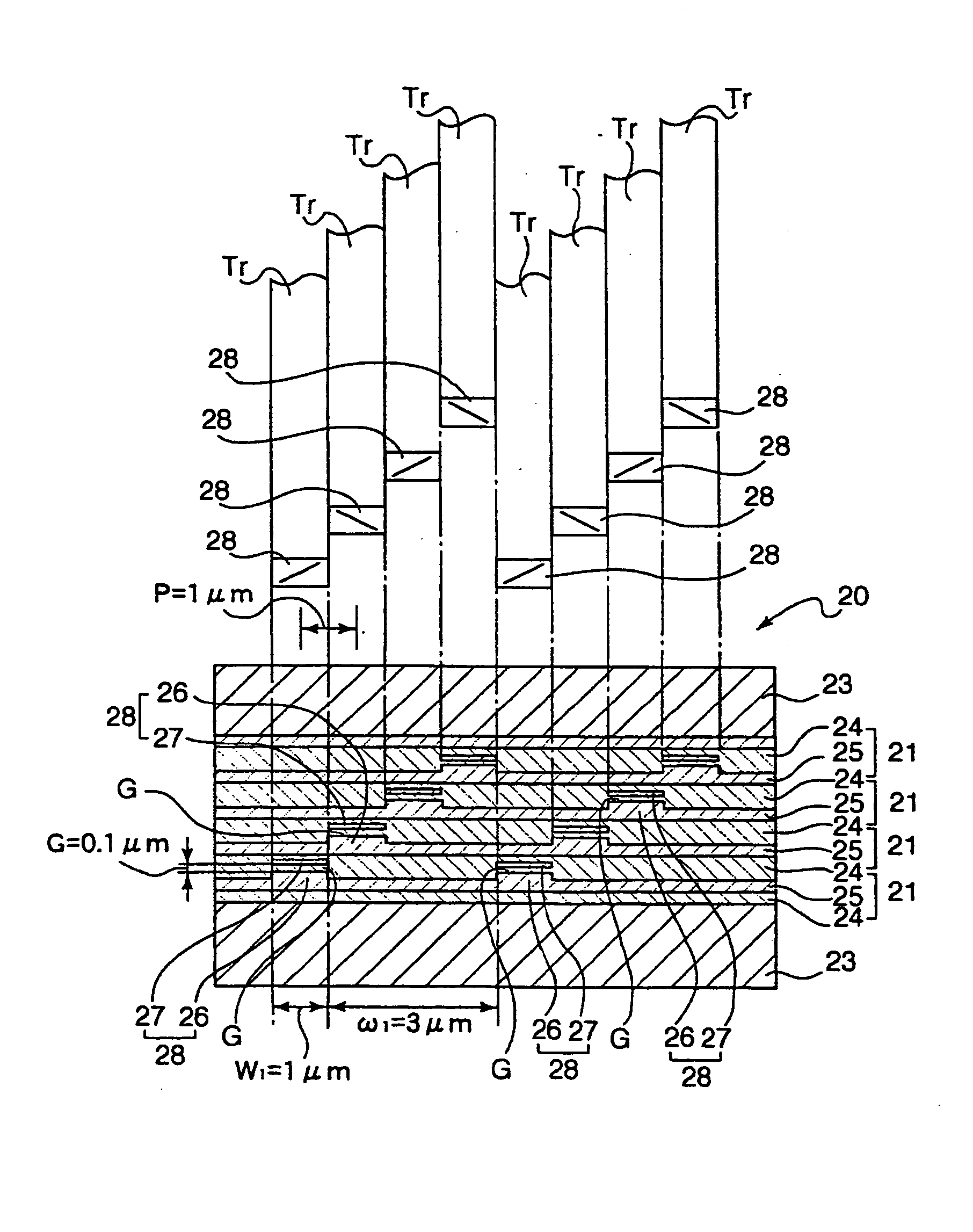

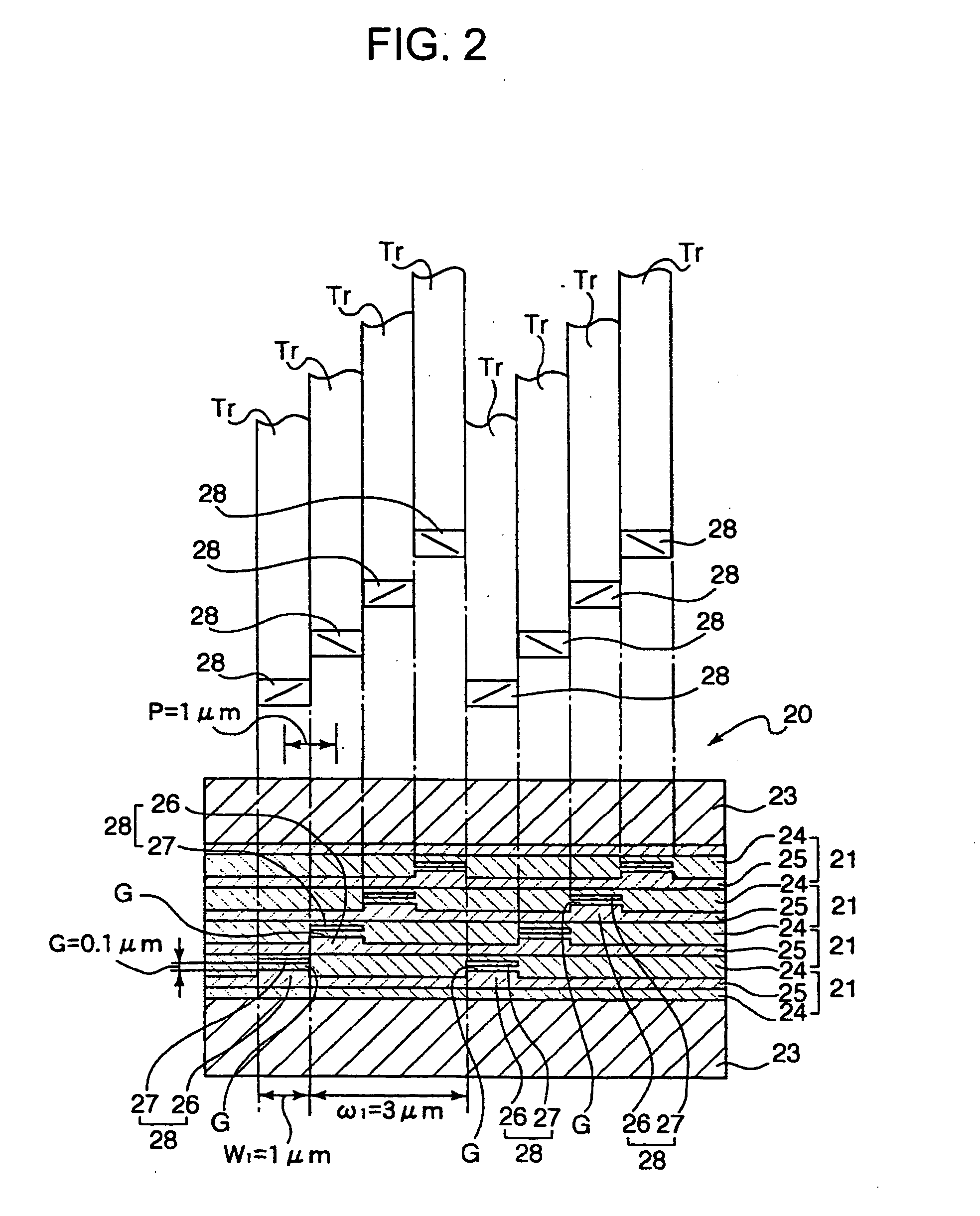

[0070] In one magnetic recording head layer 21 there are disposed two magnetic recording head elements 28, 28 separated by a predetermined distance from each other in the direction of the head width thereof. As a result, the magnetic recording head 20 thus assembled according to the present invention has eight pieces of the magnetic recording head elements 28, 28, . . . , 28 in total, as illustrated in FIG. 2.

[0071] Any two magnetic recording head elements 28, 28 adjacent in the direction of lamination via an insulating layer 24 are made share one common layer of insulating layer 24. As a result, the magnetic recording head 20 is composed by alternately laminating five layers of insulating layers 24, 24, . . . , 24 and four layers of magnetic film layers 25, 25, . . . , 25 between the bottom non-magnetic substrate 22 and the upper non-magnetic substrate 23, more specifically such as “the bottom nonmagnetic substrate 22-insulating layer 24-magnetic film layer 25-insulating layer 24-m...

second embodiment

[0095] Also, in the magnetic recording head 20A according to this second embodiment of the present invention, likewise the case of the magnetic recording head 20 according to the first preferred embodiment, because that a width of each of the magnetic recording head elements 28A, 28A, . . . can be reduced and that an alignment error between each of the magnetic recording head elements 28A, 28A, . . . can be minimized, narrower recording tracks with higher density can be formed, thereby permitting realizing a magnetic recording head 20A able to respond to increasing multi-channeling.

[0096] A third exemplary preferred embodiment of the present invention is shown in FIGS. 8 to 10, as applied to a magnetic reproducing head having eight pieces of magneto-resistive effect thin film heads (hereinafter referred to as MR head).

[0097] It should be noted that the arrangement of MR heads in a magnetic reproducing head 40 according to this third preferred embodiment of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| recording density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com