Motor for electric power steering apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

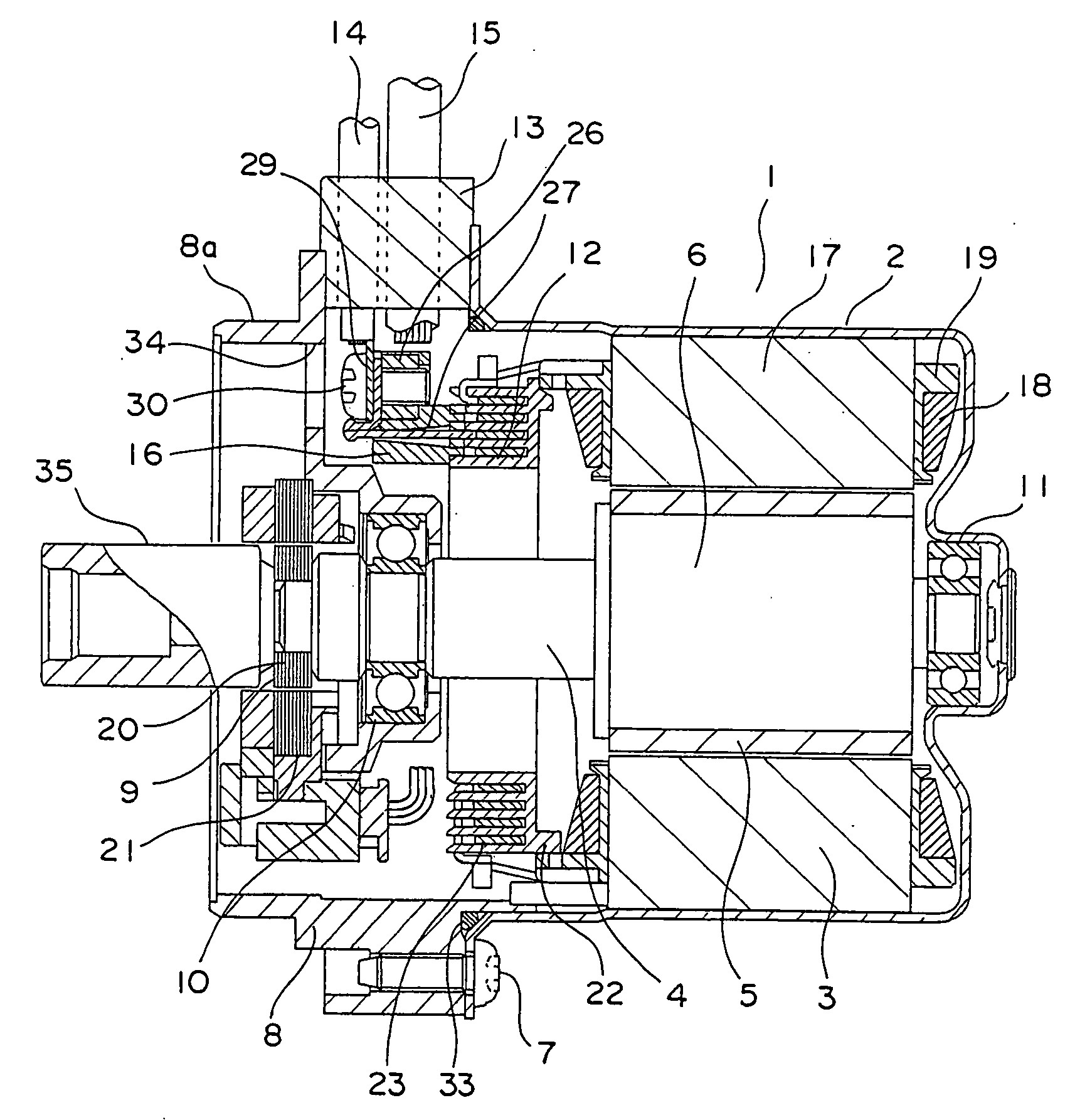

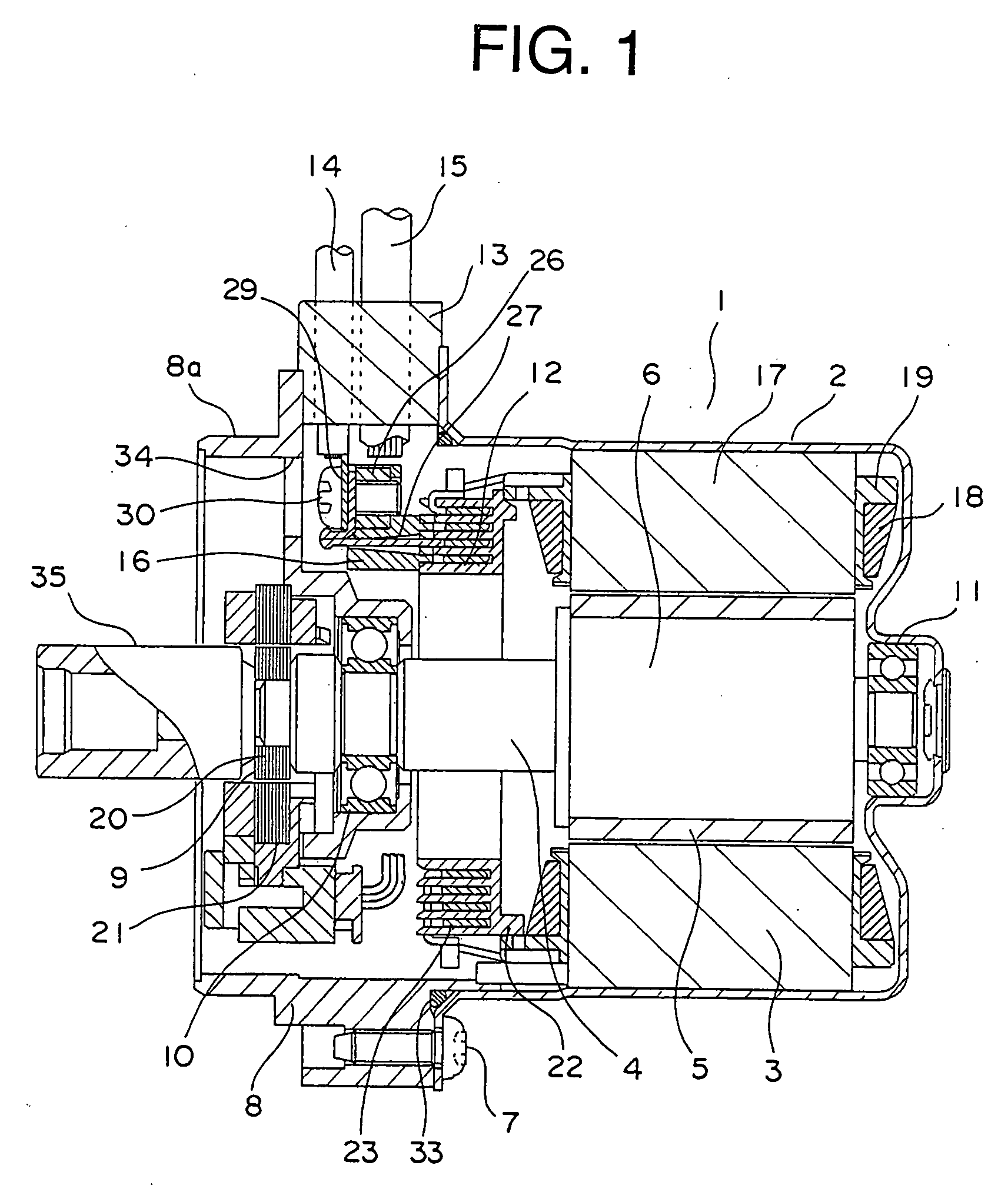

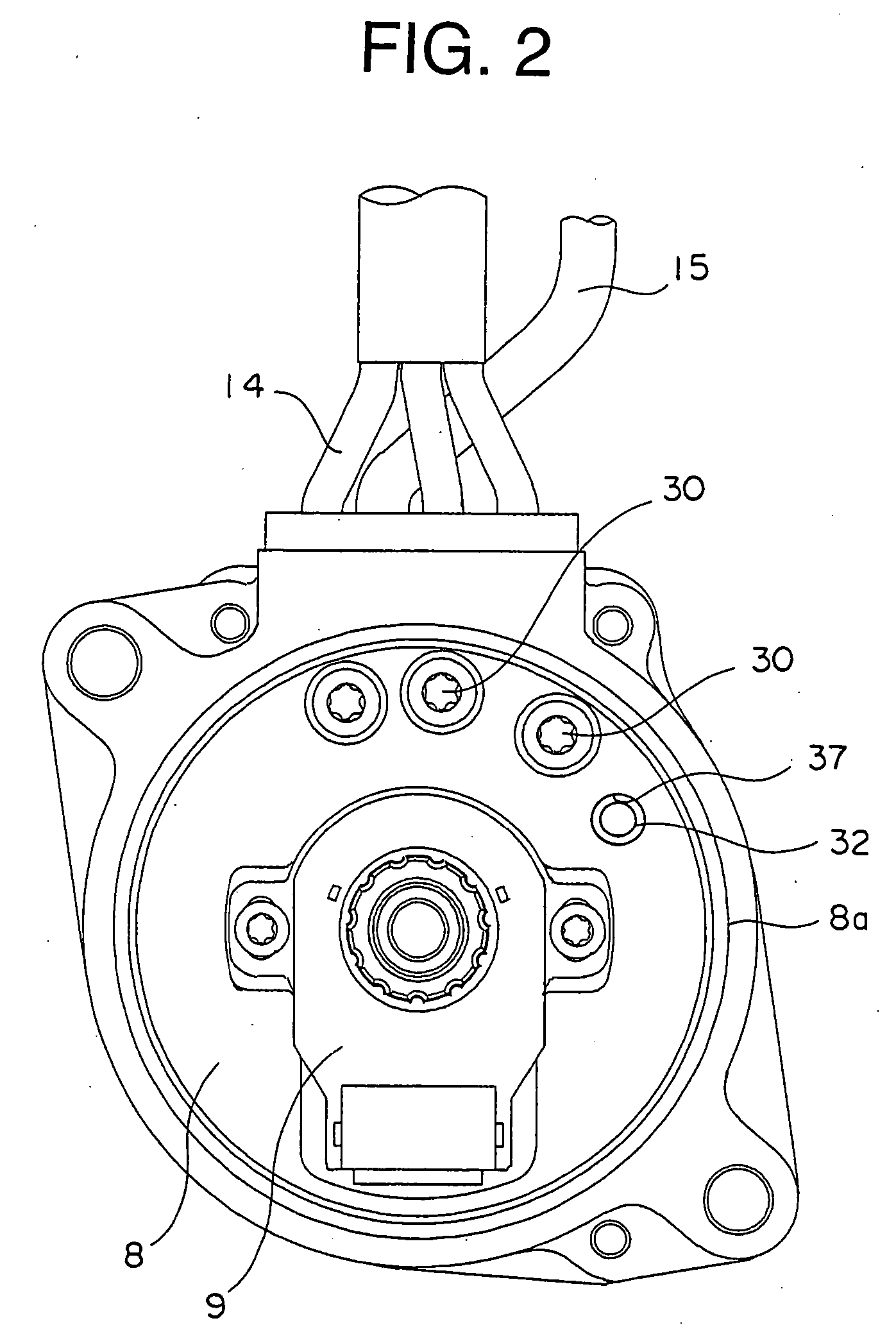

[0036]FIG. 1 is a cross sectional side view of a motor 1 for an electric power steering apparatus (hereinafter simply referred to as “motor”). FIG. 2 is a front elevational view of the motor 1 of FIG. 1. FIG. 3 is a partial perspective front elevational view of FIG. 2. FIG. 4 is a disassembled view of the motor 1 of FIG. 1. FIG. 5 is a side elevational view of the motor 1.

[0037] The motor 1 includes a bottomed cylindrical frame 2, a stator 3 fixedly attached to the frame 2, a rotor 6 composed of a shaft 4 and a cylindrical magnet 5 which is fixedly secured to the outer peripheral surface of the shaft 4 and which comprises N magnetic poles and S magnetic poles, a bracket 8 fixedly attached to the peripheral portion of the frame 2 by bolts 7 and having a work hole 34, a resolver-type rotation sensor fitted into the bracket 8, a bracket-side bearing 10 fitted into the bracket 8 for rotatably supporting one end of the shaft 4, a frame-side bearing 11 fixedly fitted into a concave porti...

embodiment 2

[0058]FIG. 16 is a cross sectional side view of a motor 40 for an electric power steering apparatus according to a second embodiment of the present invention. FIG. 17 is a front elevational view of the motor 40 of FIG. 16. FIG. 18 is a partial perspective front elevational view of the motor 40 of FIG. 17. FIG. 19 is a plan view of a bolt and a detent member of FIG. 16.

[0059] In the motor 40 of this second embodiment, as shown in FIG. 19 through FIG. 21, each connection portion 41 of an L-shaped cross section has one leg portion that protrudes from a corresponding stator-side terminal 23 toward a bracket 8 and is welded to a hexagonal head 42a of a corresponding bolt 42 which constitutes a male threaded member. The peripheral sides of each bolt head 42a are covered with a detent member 43 made of resin so as to inhibit the rotation of the bolts 42. Each of the bolts 42 penetrates through a through hole in a corresponding one of lead-side terminals 29 of respective phases, and at the...

embodiment 3

[0064]FIG. 22 is a cross sectional side view of a motor 50 for an electric power steering apparatus according to a third embodiment of the present invention. FIG. 23 is a front elevational view of the motor 50 of FIG. 22. FIG. 24 is a partial perspective front elevational view of the motor 50 of FIG. 23.

[0065] In the motor 50 of this third embodiment, a tip end of each connection portion 51 extends through a corresponding through hole 55 in a bracket 8 up to an outer side thereof, and each of lead-side terminals 52 of respective phases each having an L-shaped cross section also extends through a corresponding through hole 55 to the outer side of the bracket 8. The connection portions 51 and the lead-side terminals 52 are formed at their one ends with through holes through which male threaded members in the form of bolts 53 extend, respectively. Female threaded members in the form of nuts 54 are threaded on one ends of the bolts 53, respectively.

[0066] The construction of this thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com