Closure unit, mold for producing same, and dispenser-container incorporating a closure unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

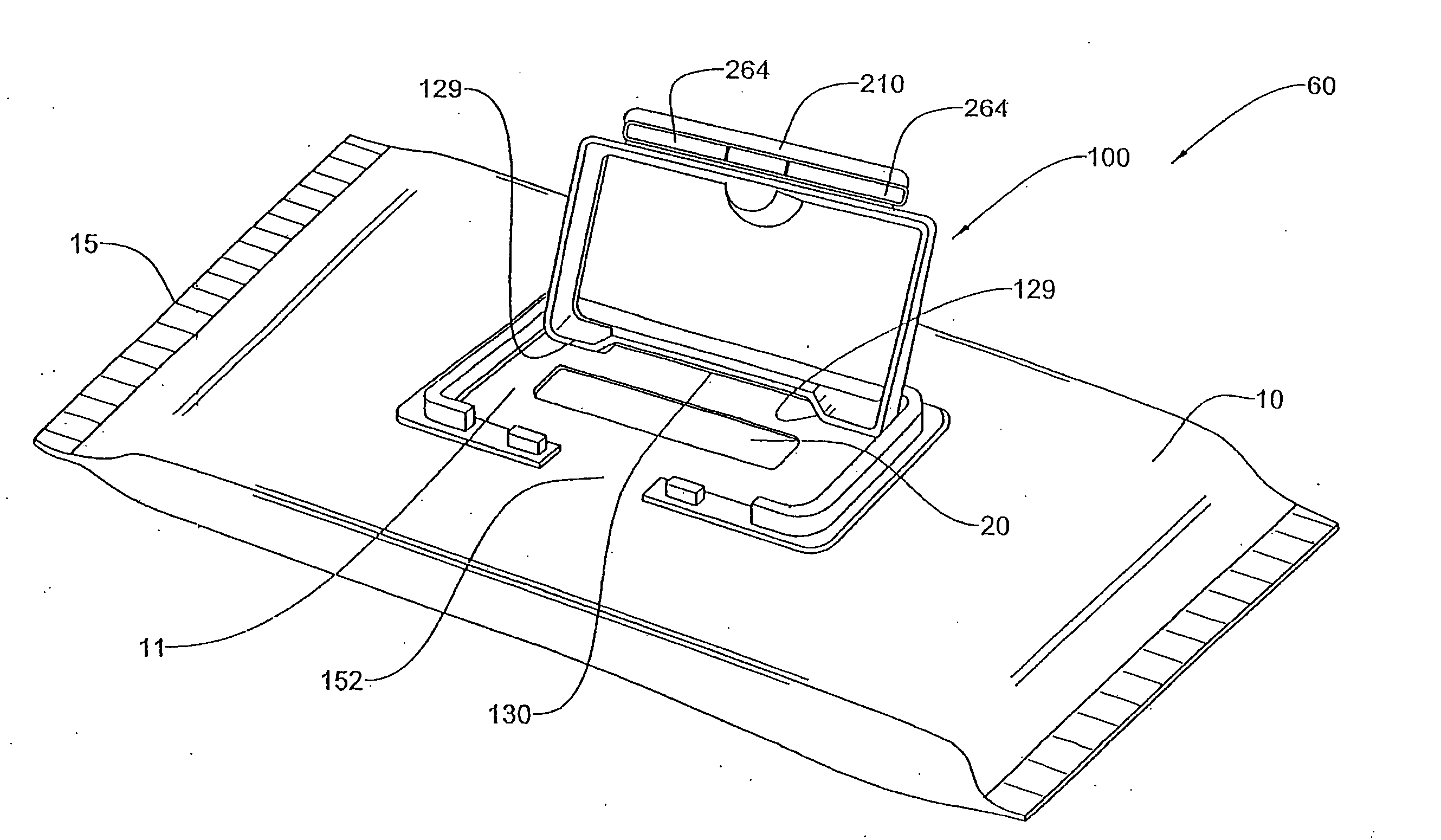

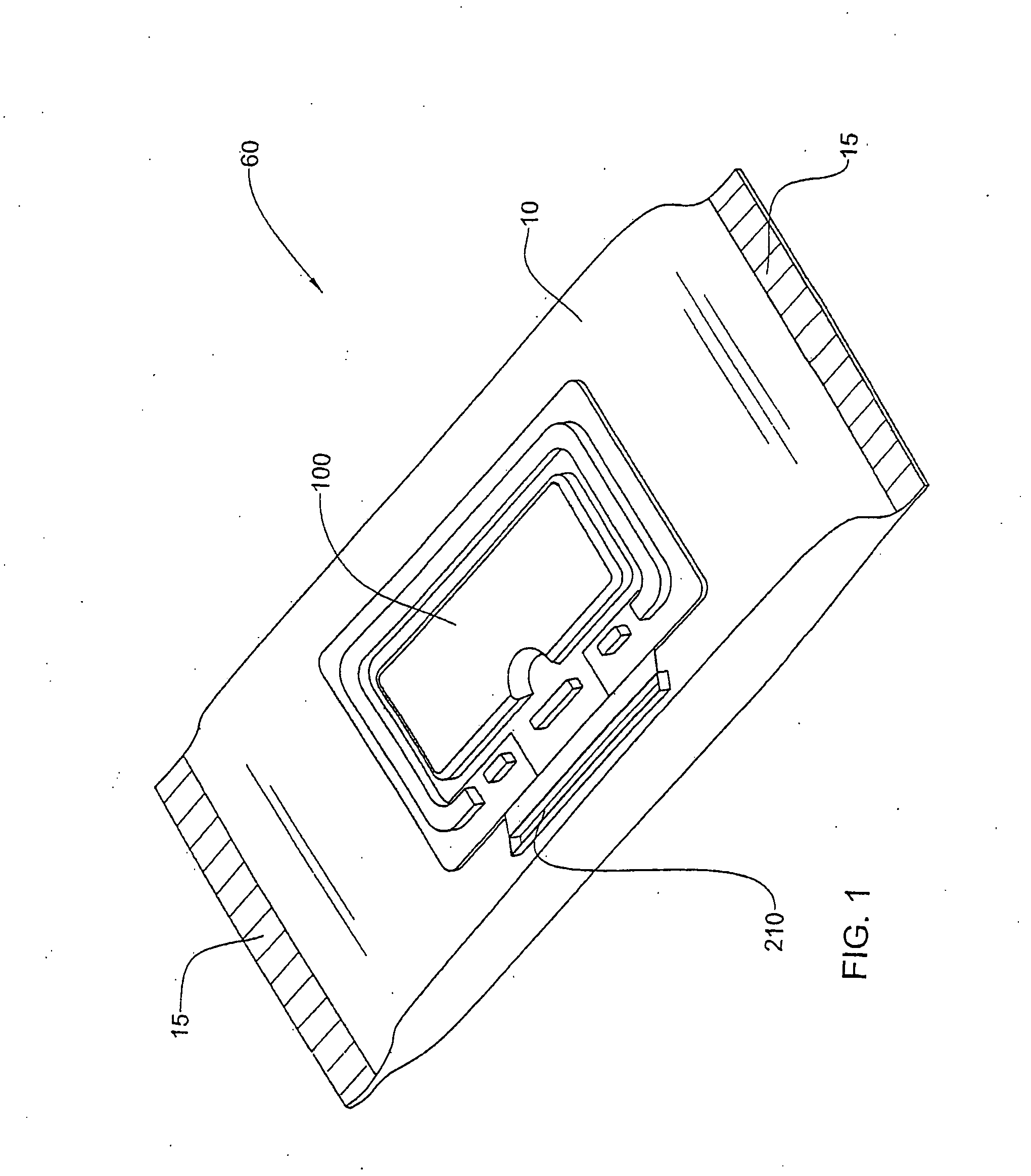

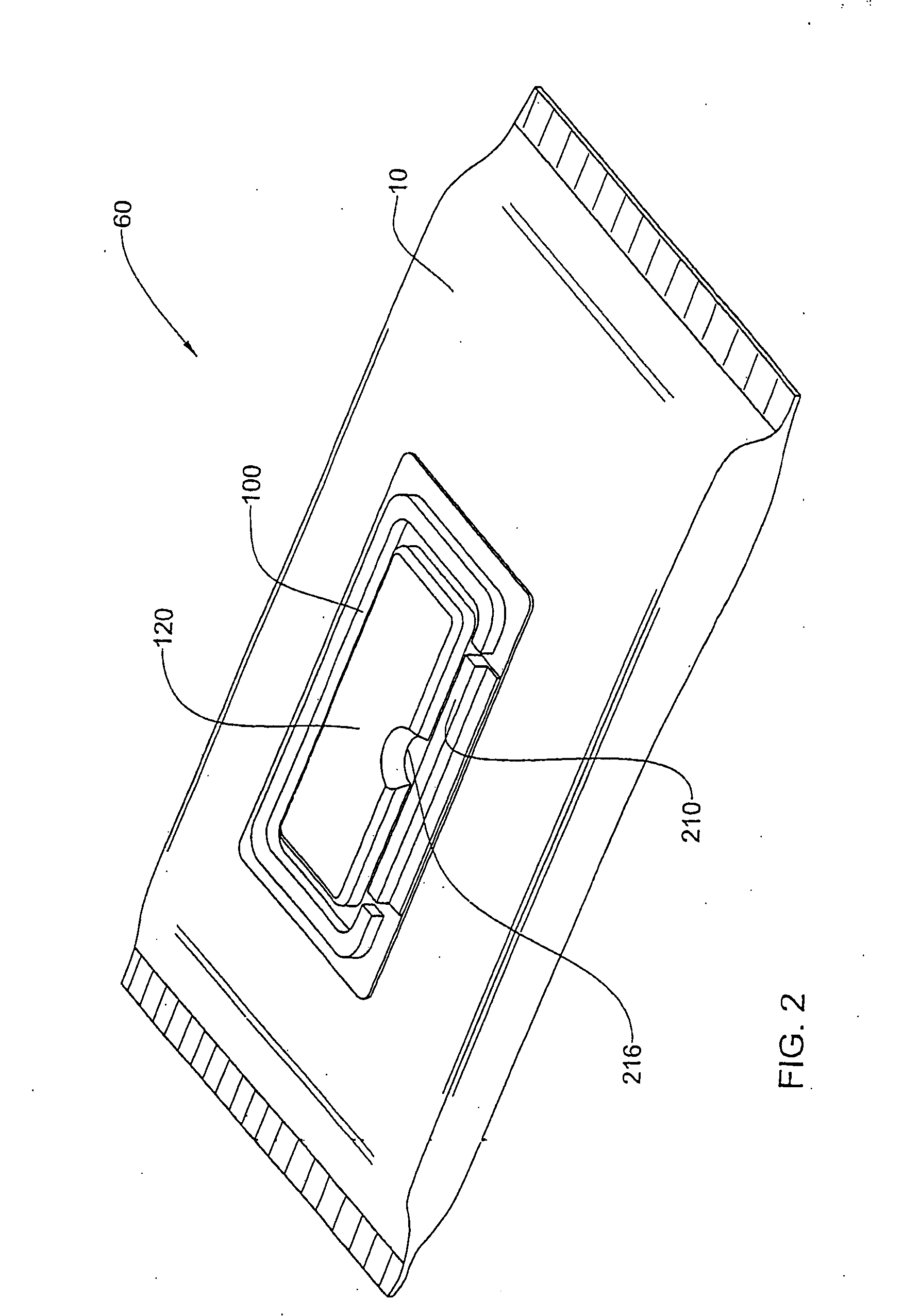

[0078] A typical dispenser-container according to the present invention is illustrated in FIGS. 1 to 3. The dispenser-container, generally designated 60, comprises a resealable container 10, which in the present embodiment may be similar to that of the conventionally known portable dispenser-container of a bag type for wet tissues. The container 10 is made from a flexible sheet suitably folded and bonded along a longitudinal join (not shown) and at ends 15 to provide an internal space that is filled with articles to be dispensed, such as tissues and the like.

[0079] The flexible sheet constituting the container 10 may comprise, for example, synthetic resins such as polyethylene, polypropylene, polyamide, polyester, and polyvinyl chloride in the form of a film, and the film may be a single layer or a laminated layer. The film may be a laminated layer of the above-mentioned film and an aluminum foil or paper, and the container 10 is in any case deformable.

[0080] The sheet constituting...

third embodiment

[0115] While the faces 411 and 429 are sloping at acute angles with respect to the surrounding frame 440, these angles with respect to a vertical datum are indeed very small, and thus the natural elasticity of the material from which the unit 400 is formed is sufficient to remove such a part when formed over suitable molds. Thus, by non-overlapping it is meant also to include embodiments such as the third embodiment, in which at least some parts may be disposed at an acute angle with respect to the frame, for example.

[0116] When formed as an integral unit, the flap 420 is joined to the frame 440 via a fracturable or otherwise separable break line 450, in the form of a “C”, excluding the hinge means 430. The break line 450 thus extends from one end of the pivot line of the hinge means 430, between the frame 440 and the border strip 428, and to the other end of the pivot line of the hinge means 430. The break line 450 may be perforated, or pre-weakened, or formed with substantially le...

seventh embodiment

[0166] The closure unit 700 of the seventh embodiment comprises a locking arrangement 780 for reversibly locking the flap 720 with respect to the frame 740 in a substantially sealing manner. The locking arrangement 780 according to this embodiment comprises the free leading edge 728 of the tab 725 and a complementary lip 785 comprised on the front part of the rib structure 750, the lip 785 projecting from the rib structure 750 in a rearwards direction towards the hinge arrangement 730. When it is desired to close the flap 720, this is rotated about the hinge arrangement 730, until the leading edge 728 is snapped into position below the lip 785. When it is desired to open the closure unit 700, the user presses the recess 722 in a direction towards the hinge arrangement 730. The resilience of the closure unit 700, and / or the play allowed for in the hinge arrangement 730, allow the leading edge 728 to be disengaged from the lip 785, and thus the flap 720 may be opened.

[0167] The closur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com