Apparatus and method for aircraft cabin noise attenuation via non-obstructive particle damping

a technology of aircraft cabin and damping, applied in the field of noise reduction apparati, can solve problems such as energy dissipation, and achieve the effect of high damping, durable and reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

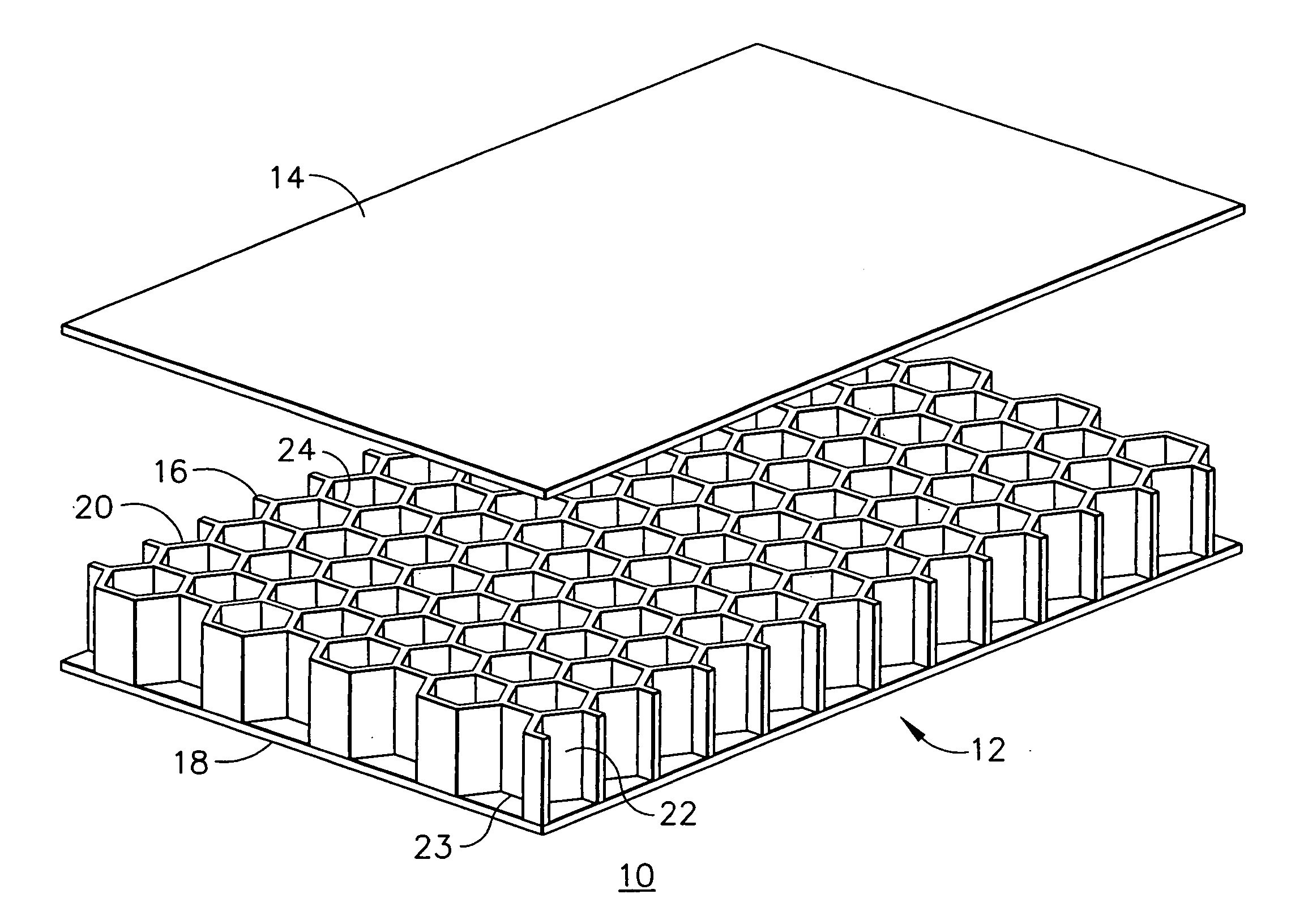

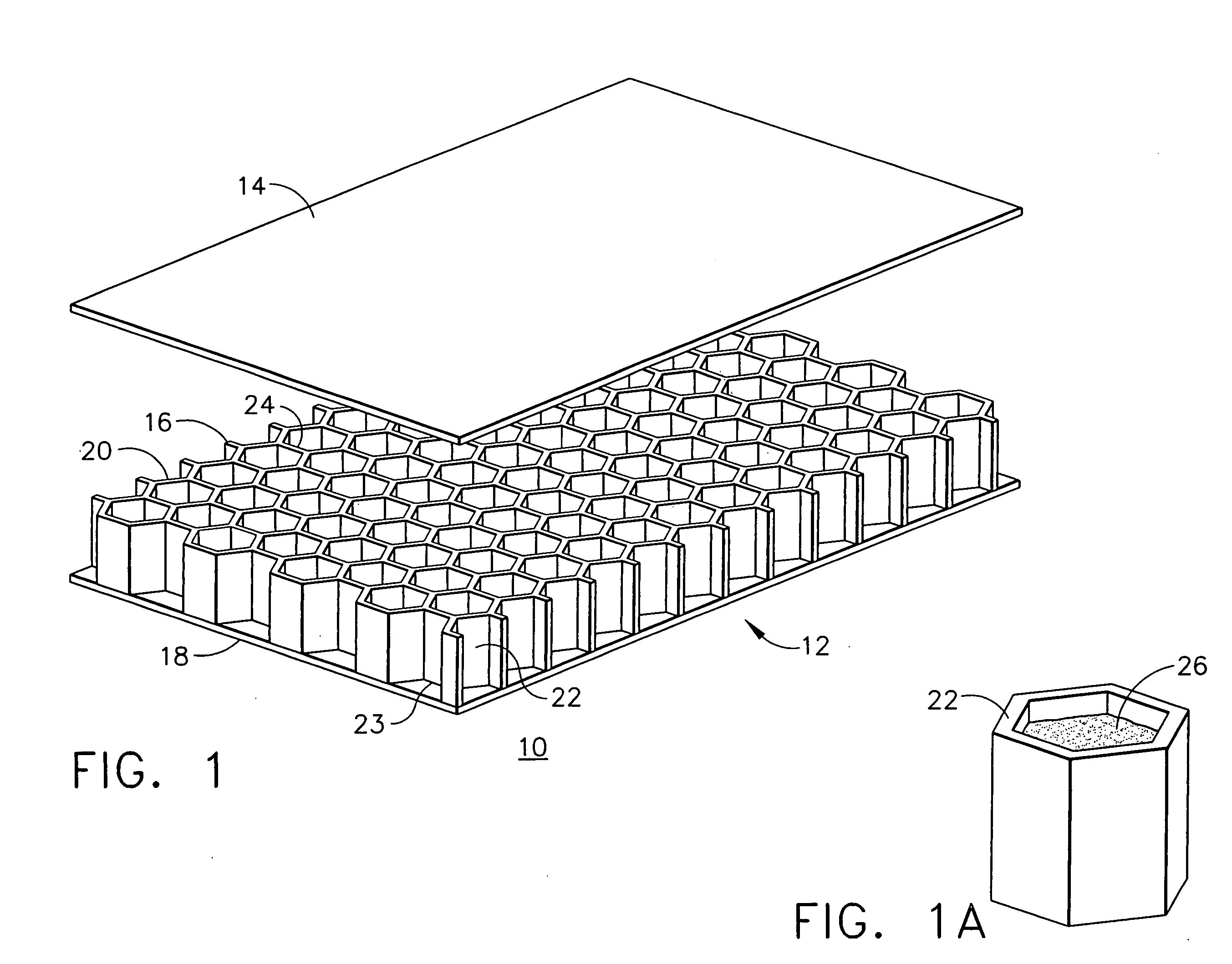

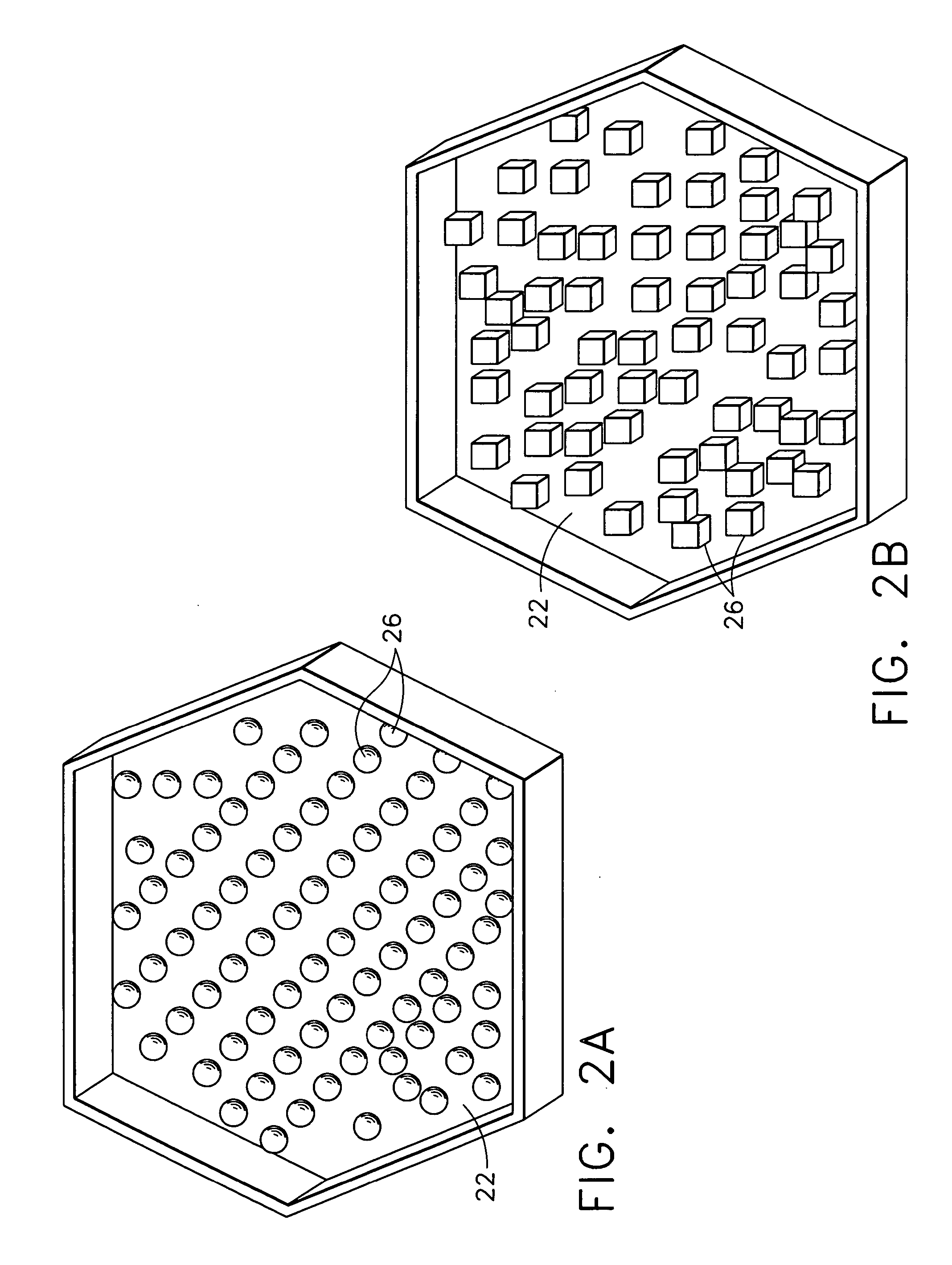

[0019] The materials an aircraft manufacturer may use during construction are subject to various design parameters. For example, in addition to desiring that the various structural materials used in the aircraft possess a high degree of strength, such materials also need a low degree of flexibility and a relatively low mass. To successfully optimize these design parameters, manufacturers have come to utilize structural elements commonly referred to as “honeycombs” or “honeycomb structures.” For purposes of the present invention described herein, “honeycomb structures” are structural units (i.e., walls, floors, ceilings, etc) of an aircraft comprising a substantially hollow middle portion, generally formed of hexagonal (or other similar shape) rows of hollow cells or cavities, resembling the structure of a honeycomb in a beehive.

[0020] One advantage of honeycomb structures is that they can be made of types of materials both preferred and desired by aircraft manufacturers, while prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com