Distribution system of pet bottle for drinking water and beverage

a technology of drinking water and distribution system, applied in the direction of transportation and packaging, contraceptive devices, packaging goods types, etc., can solve the problems of large public works, insufficient strength to correspond to automobiles, and the cost of recovering the emptying body of the pet bottle body becomes a large burden on the public works, so as to achieve the effect of reducing the vertical width (height) and easy manufacturing of the pet bottl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

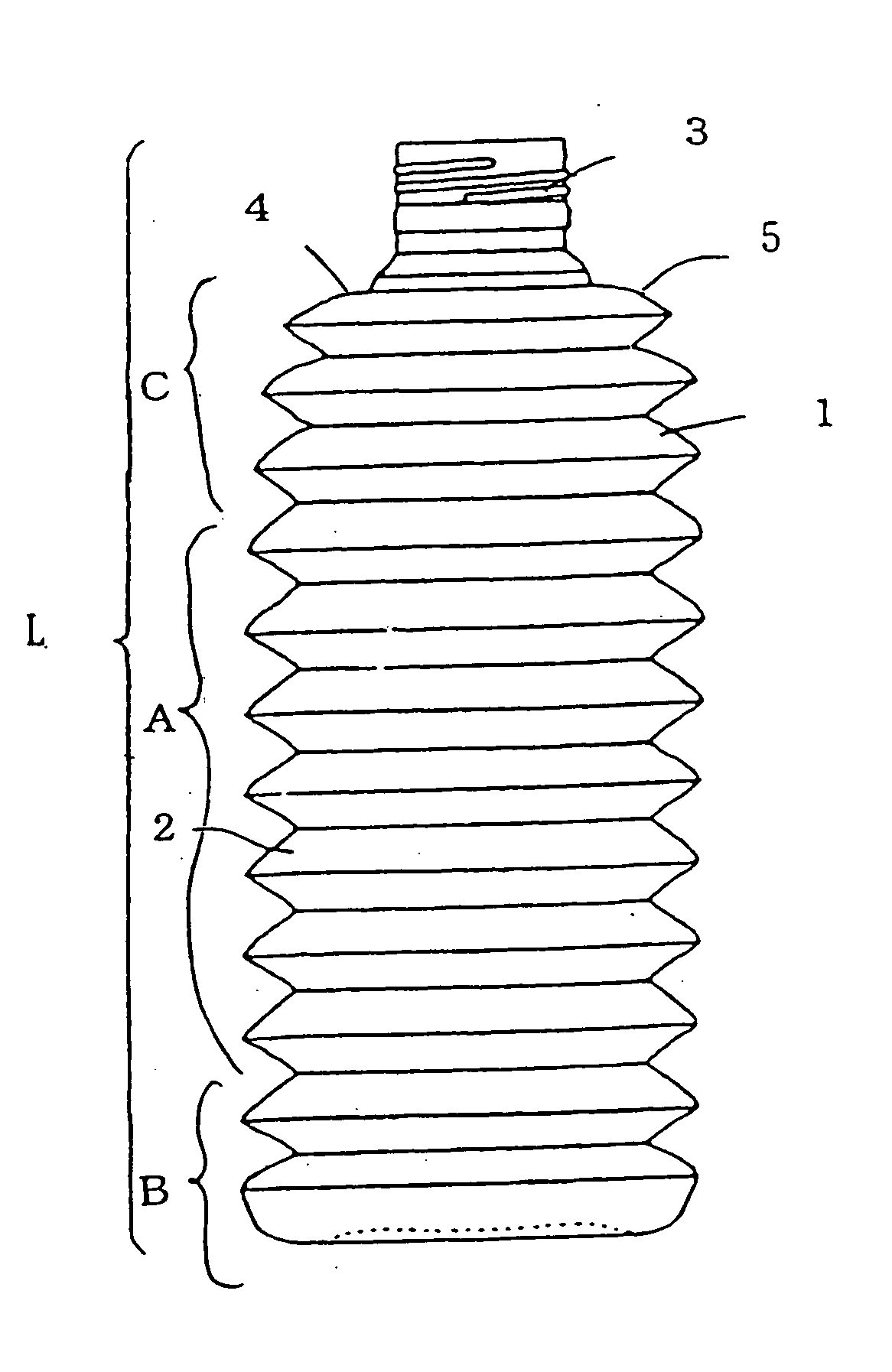

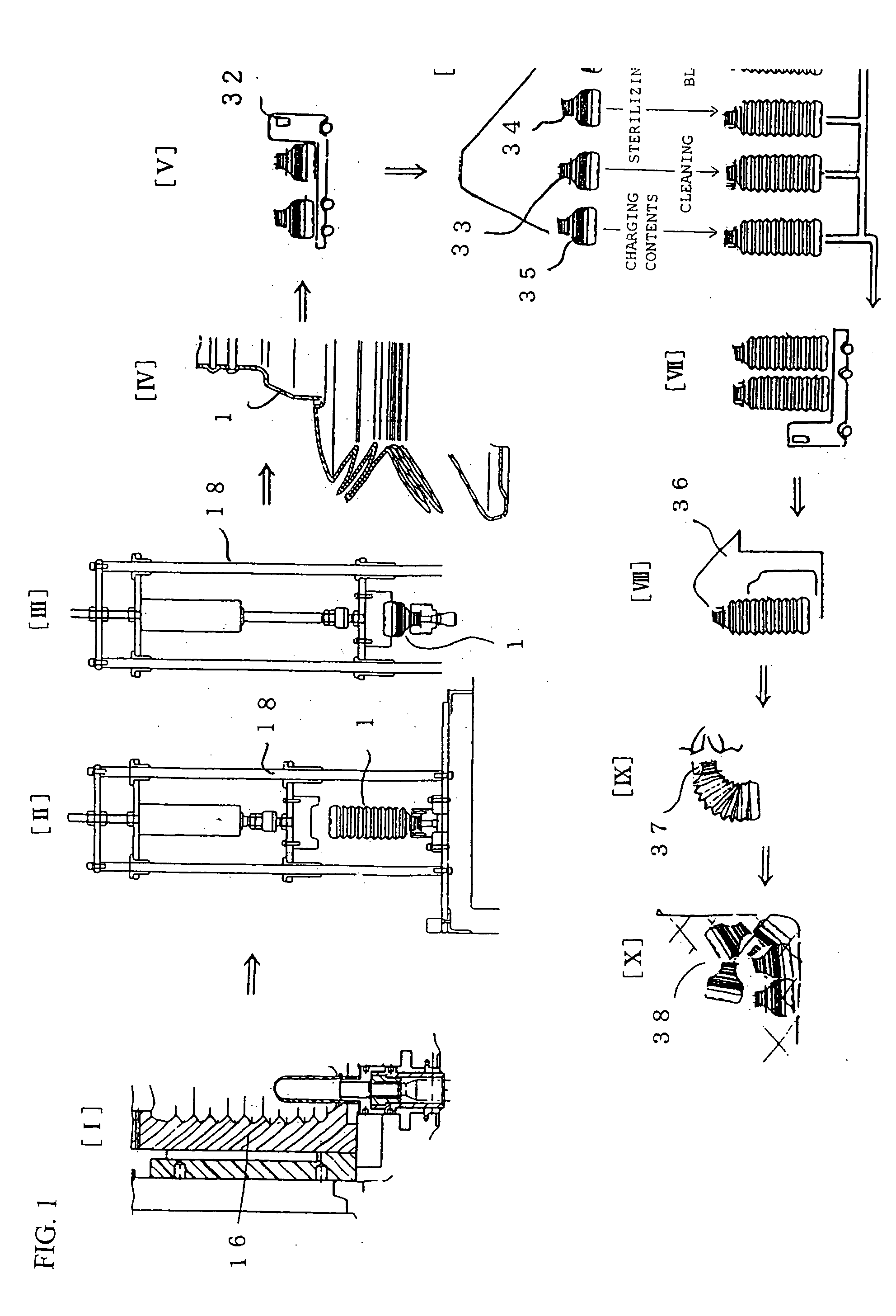

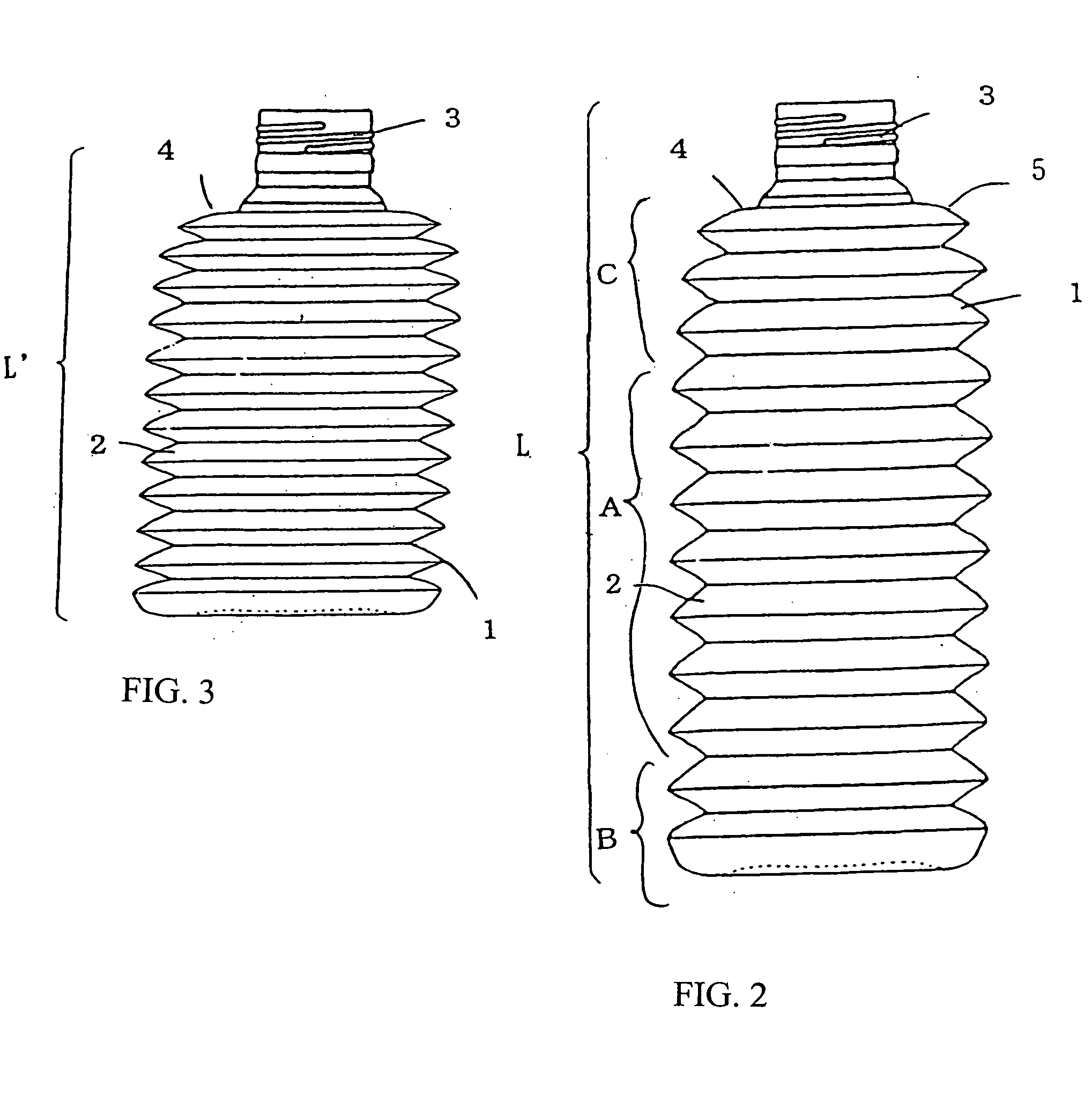

[0103] Reference numeral (1) in the drawings denotes a PET bottle body obtained by a manufacturing method of the present invention, FIG. 2 shows a state in which the PET bottle body (1) is removed from a die body (16) which molds the PET bottle body (1), namely, a volume height (L) thereof is equivalent to that when a content is charged into the PET bottle body (1).

[0104]FIG. 3 shows a state after a forming work in a forming work mechanism (18) for compressing the PET bottle body (1) in a vertical direction, namely, the volume height (L′) is in a state of zero, and the above described volume height can be normally reduced to about ½ to 1 / 10 of the volume height (L).

[0105] On explaining an embodiment of the present invention based on the drawings, the characteristics of the present invention can be easily understood if the structure and the operational effects of the PET bottle body (1) itself are understood, and therefore the explanation thereof will be made. Namely, the PET bottl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com