Fireplace hydronic heating

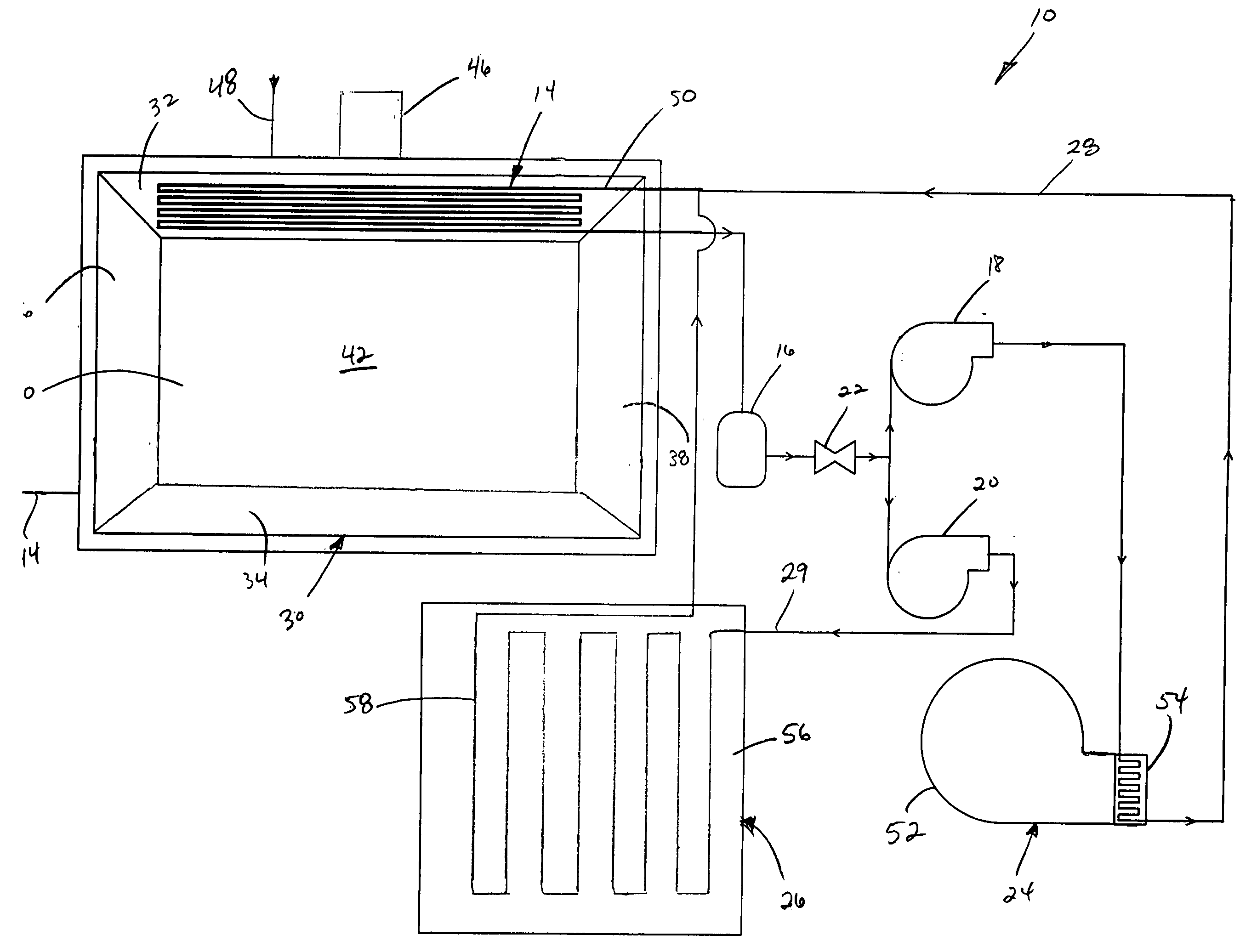

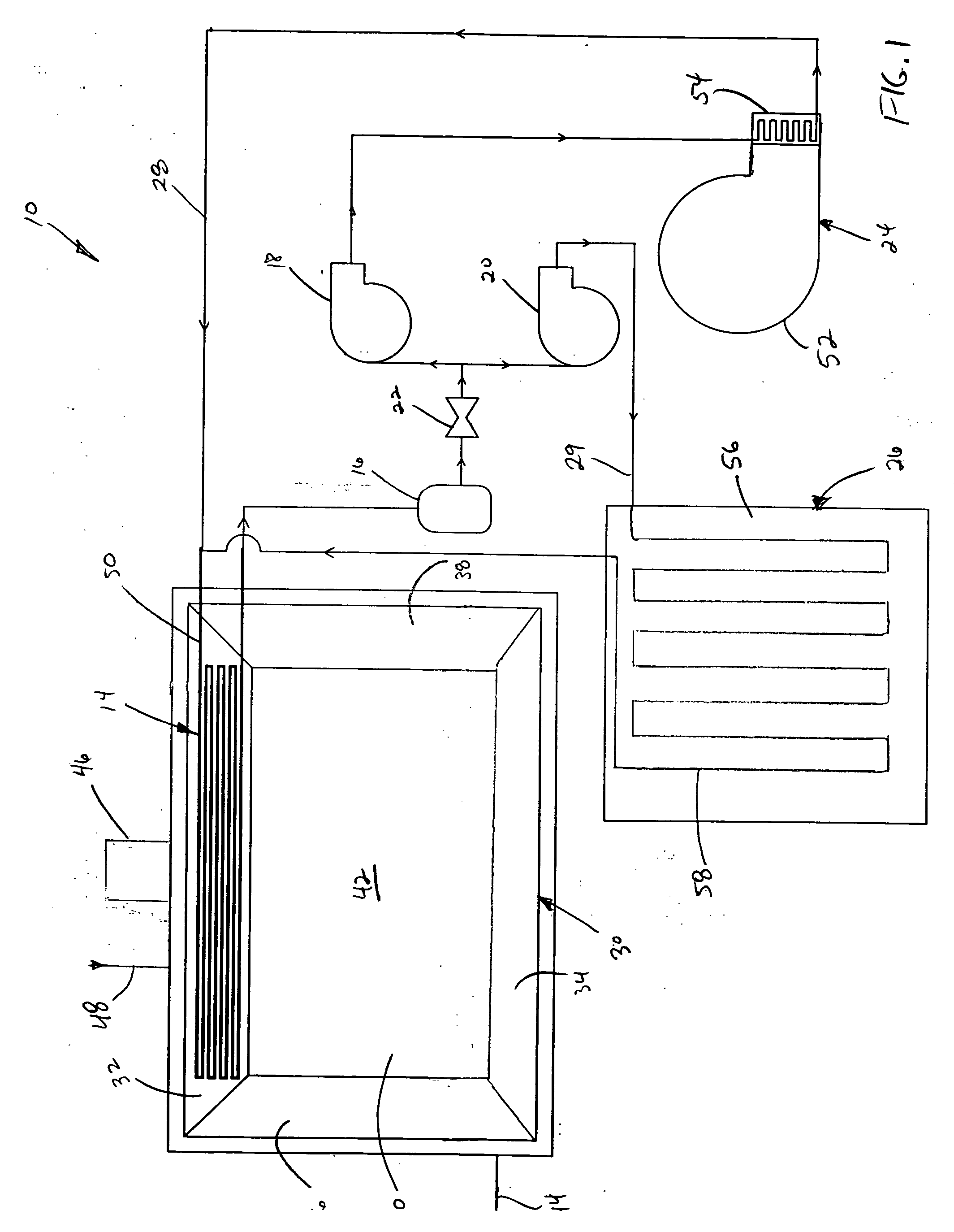

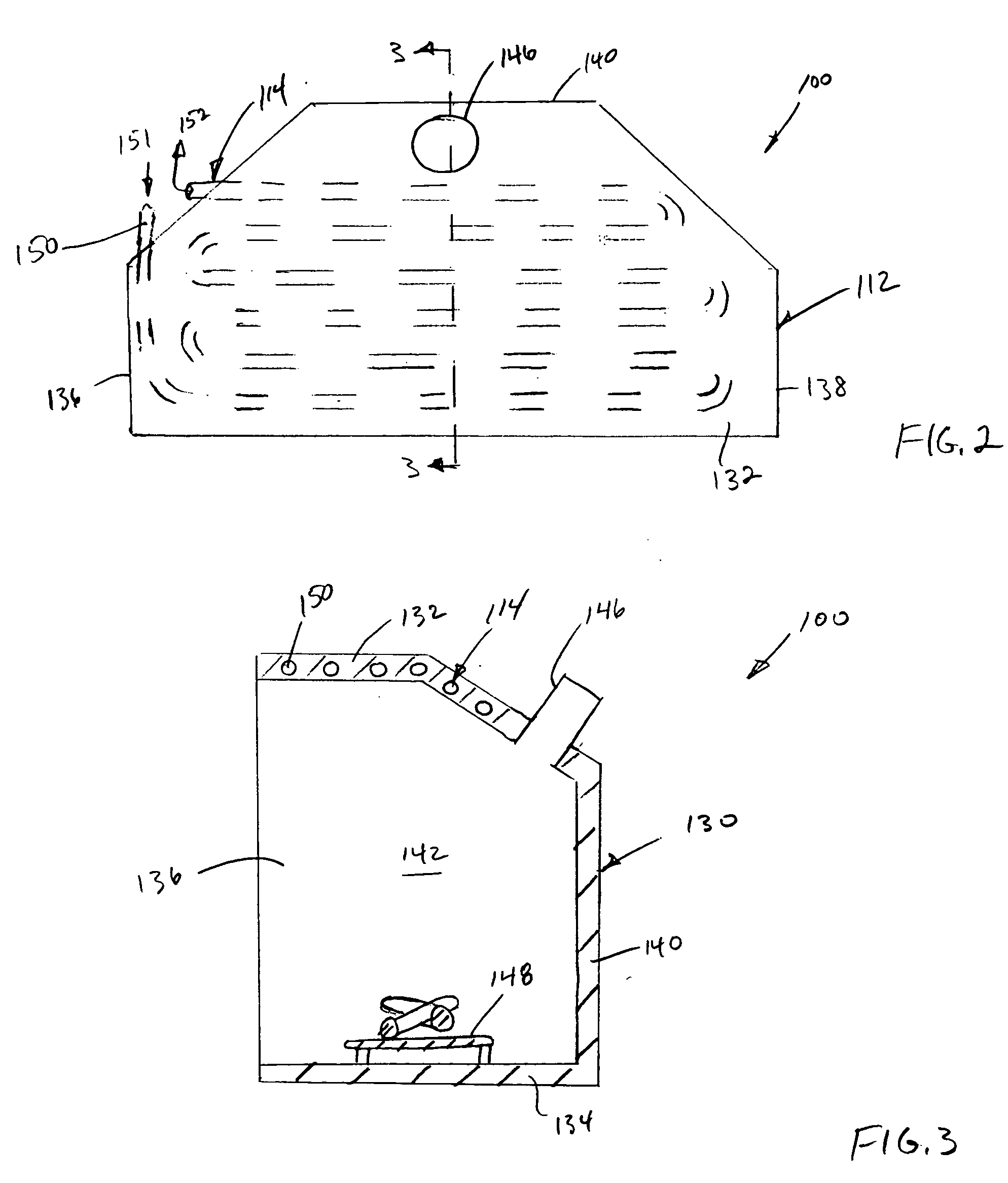

a hydronic heating and fireplace technology, applied in the direction of heating types, ways, stoves or ranges, etc., can solve the problems of unfavorable fireplace functions, damage to the building structure, and unfavorable fireplace functions, so as to improve the manufacturability of the hydronic heating system and eliminate condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0031] In an example hydronic heating system application, the heating system is used to heat a 1,500 square foot room having 8 foot ceilings and a cement floor. Liquid-filled conduits are embedded in the cement floor and coupled to liquid-filled conduits embedded in a panel of a combustion chamber enclosure of the heating appliance. The liquid being heated in the hydronic heating system is a mixture of about 50% water and 50% glycol and is carried in half-inch HEPEX™ tubing between the heating appliance and the cement floor. The desired temperature of the air in the room is 70° F. and the temperature outside of the room is 11° F. In order to heat the room to the desired temperature, the heating appliance generates about 13,300 BTUs / hour to generate a liquid temperature in the liquid-filled conduits of the combustion chamber enclosure of about 80° F. The heated liquid is pumped to the liquid-filled conduits of the cement floor at a flow rate of about 2.9 gal / min to heat the cement fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com