Tailored Fischer-Tropsch synthesis product distribution

a technology of fischertropsch and product distribution, applied in the field of fischertropsch synthesis, can solve problems such as difficulty in controlling the products resulting from synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Catalyst Preparation and Characterization

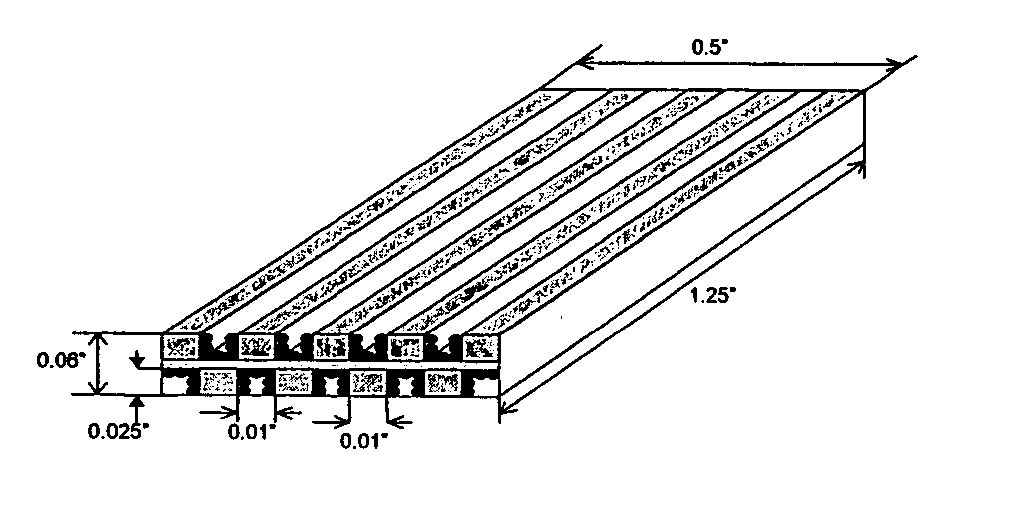

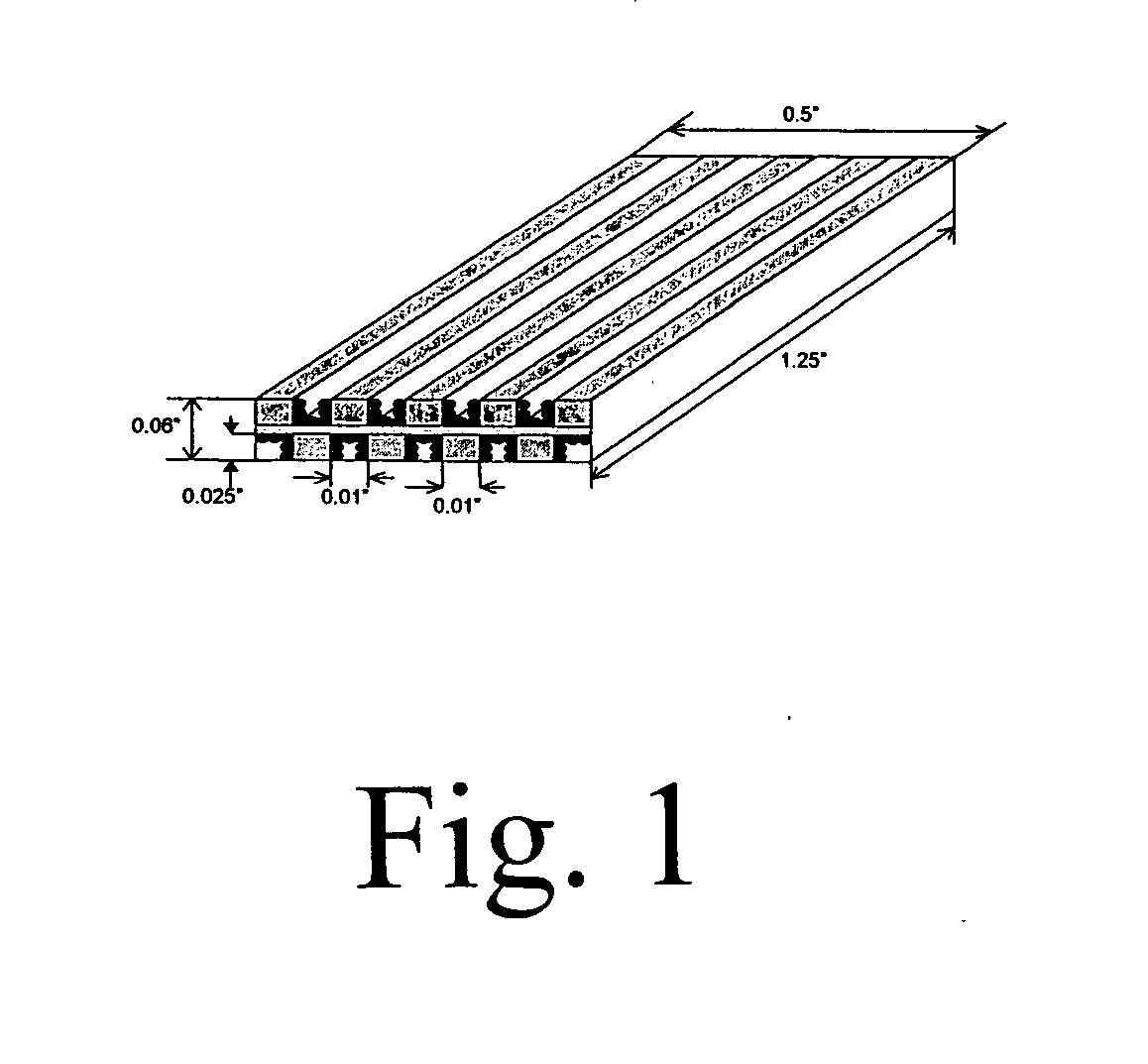

[0042]FIG. 1 is a schematic drawing illustrating the geometry of a monolith catalyst used in the examples. The general dimension of each monolith was 0.5″×0.06″×1.25″. The catalyst substrate 102 was made of aluminum for its high thermal conductivity. The substrate was mini-structured with double-side alternative valleys and peaks. There are 50 valleys for being coated with catalyst ingredients. The width of each valley was 0.01″. Valley depth: 0.025″, Peak width: 0.01″.

[0043] To prepare highly porous catalyst layers on the substrate, a sequential washcoating-impregnation process was applied. The surface of aluminum substrate was first oxidized in air at 550° C. to enhance the adhesion to catalyst layers. A solution with optimized rheological properties was used to achieve uniform coats with desired porosities. PQ Al2O3 (Nyacol) was mixed with poly block copolymer, Pluronic F-127 (HO(CH2CH2O)106(CH2CH(CH3)O)70(CH2CH2O)106H) and ethyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com