Fire retardant adhesive tissue

a technology of adhesive tissue and adhesive layer, applied in the direction of film/foil adhesive, antifouling/underwater paint, printing, etc., can solve the problems of easy tear and difficulty in working with materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0044] A flame retardant paste dispersion formulation as follows is prepared by adding ingredients under constant mixing:

IngredientAmount (weight %)Water41Spartan FR4822Mirox HP (thickener)6EMS Griltex L365E P1 (adhesive)22.5Mirox OX (printing agent)8.5

[0045] The percent solids for the final paste mix is between about 28 to 32%. The viscosity is between about 1,800 and 3,500 cps when tested on the Brookfield RVT using a #4 spindel at 20 RPM. It is anticipated that this composition will impart flame resistance to adhesive coated paper and provide flamer retardant solids of approximately 10 weight percent.

example 2

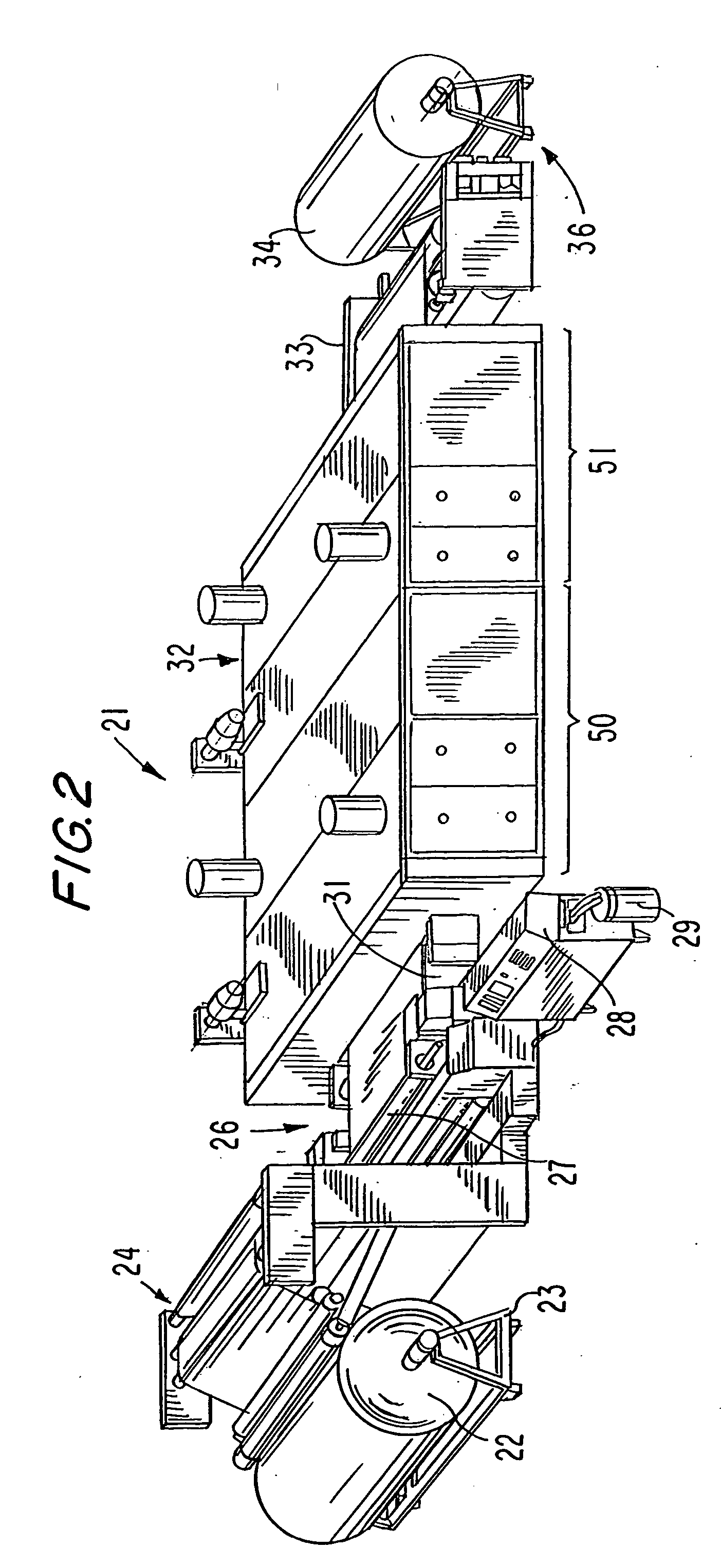

[0046] An uncoated tissue paper having a weight specification between 17.0 and 21.0 g / m2 (0.50 and 0.62 oz / yd2) from Cellu Tissue Corp. of Grouvemeur, N.Y., and is their product Grade 3284. It is also known as 11 pound paper and is coated utilizing dispersion prepared in Example 1 in a screen paste coating apparatus illustrated in FIG. 2. The line speed is maintained between about 18 to 23 m / min (20 to 25 yds / min) The coated dry paper after leaving the oven is batched up at the lines batcher end 2,000 yard rolls ready for shipment. Flame testing is done in a composite by laminating the resulting coated tissue paper to a high loft polyester felt. It is then tested using the Federal Motorvehical Safety Standard #302 (MVSS #302) test procedure.

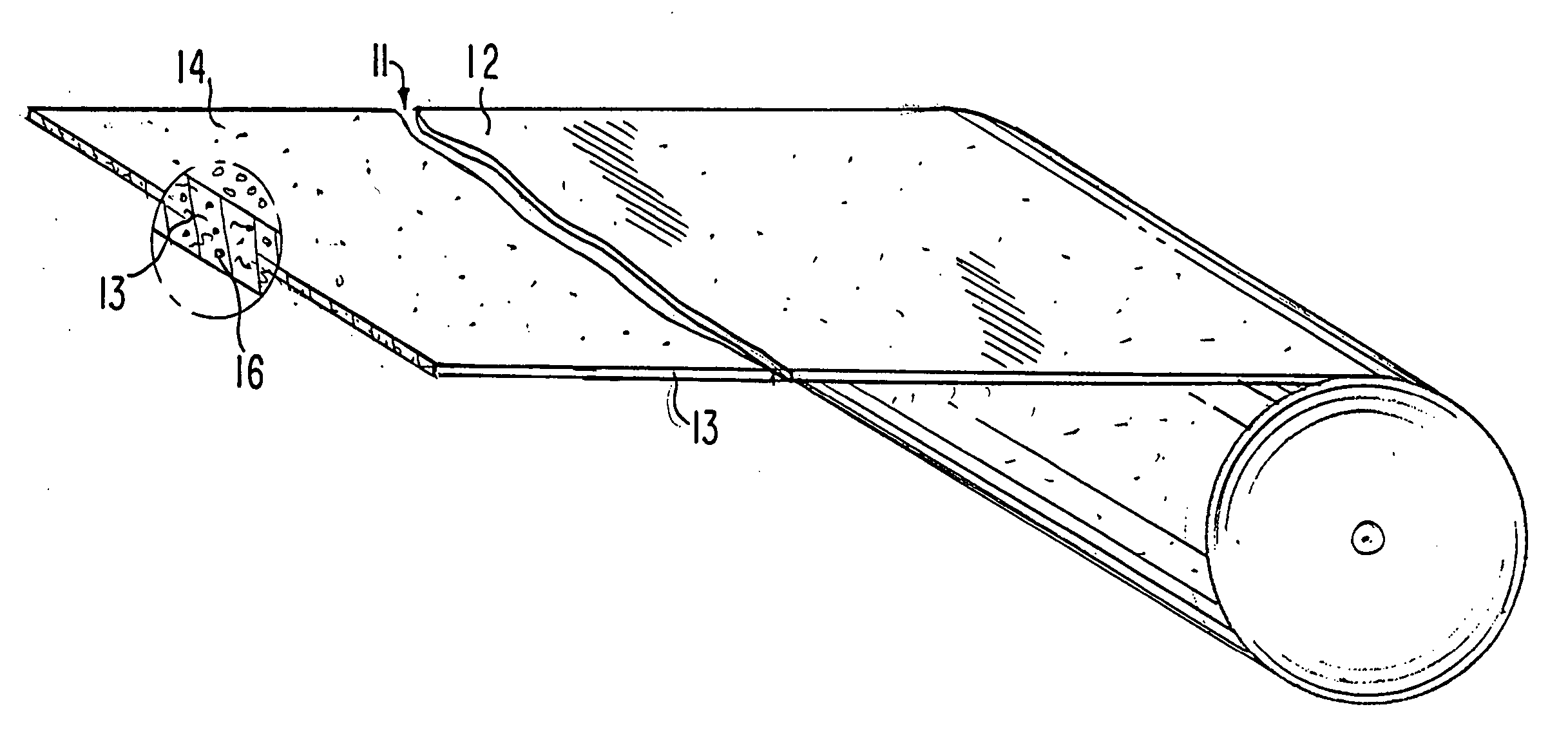

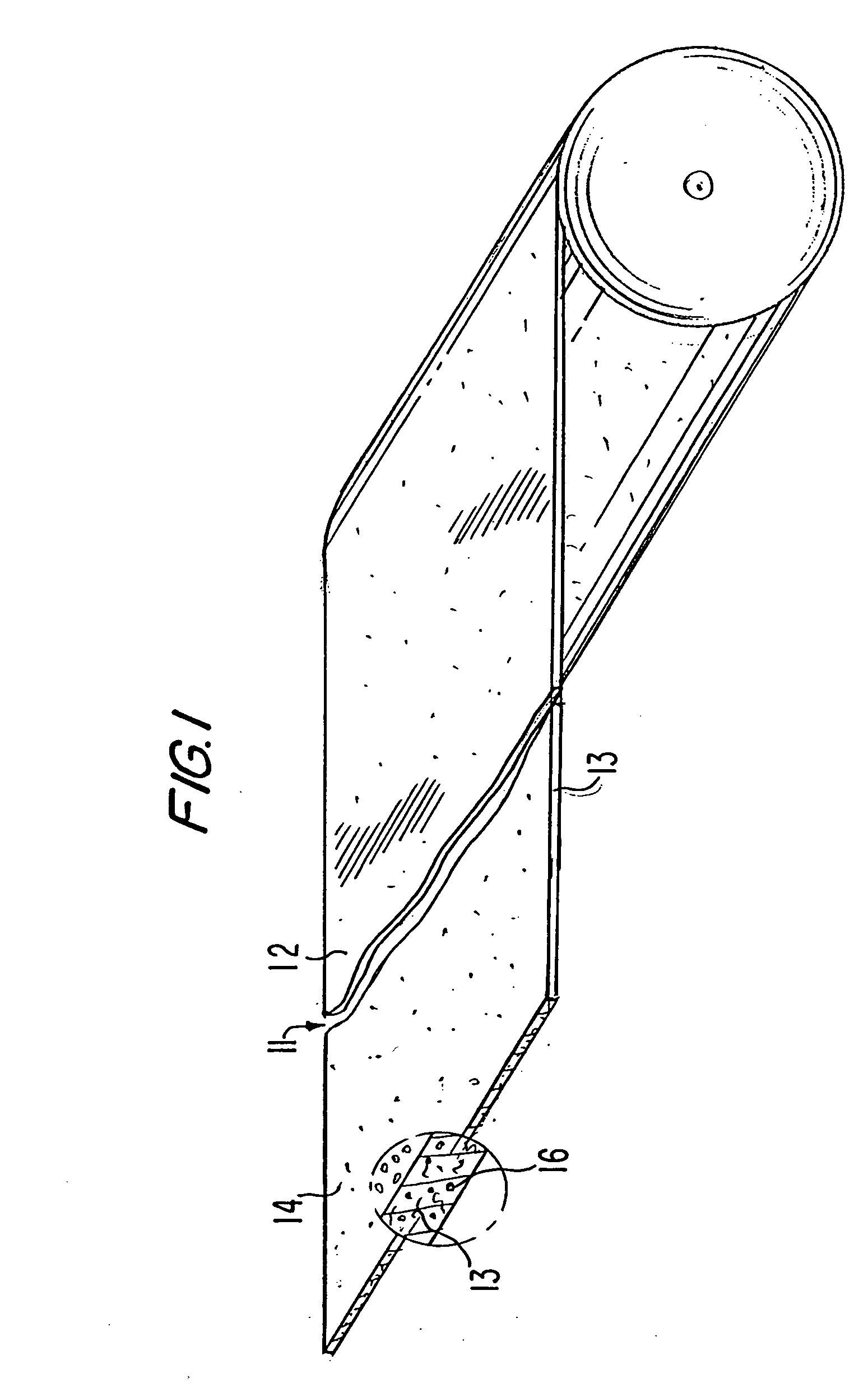

[0047] A flame retardant adhesive tissue in accordance with the invention provides a coated with dots of a thermoplastic adhesive and an inorganic flame retardant dispersed throughout the tissue fibers. The coated paper is particularly well suit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com