Indirect evaporative cooling of a gas using common product and working gas in a partial counterflow configuration

a technology of working gas and common product, which is applied in the field of indirect evaporative coolers, can solve the problems of high cost of desiccant-dried air use, and achieve the effects of increasing the temperature of the working gas, increasing the latent heat load of the working air, and increasing the enthalpy of the exhaust air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

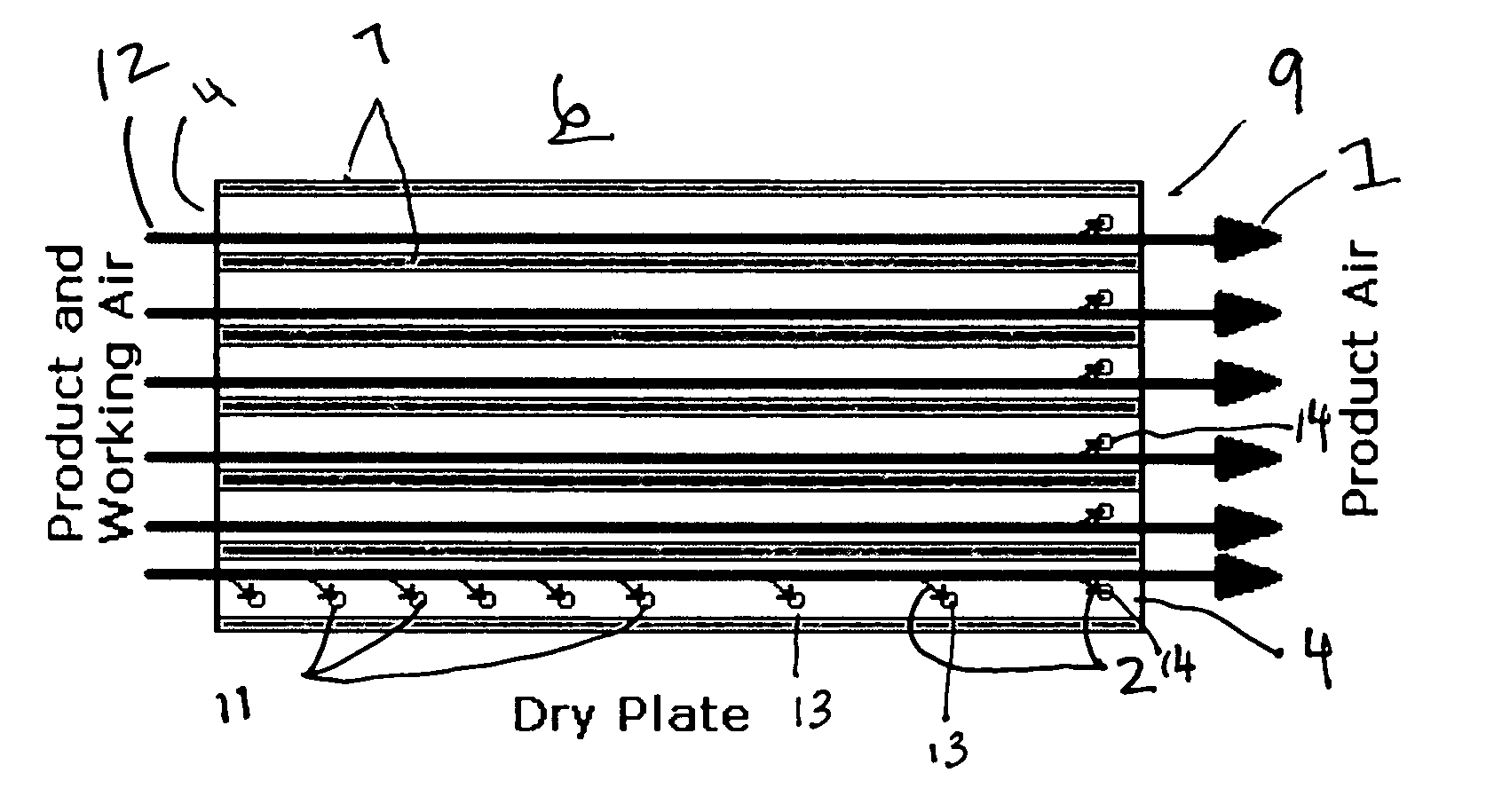

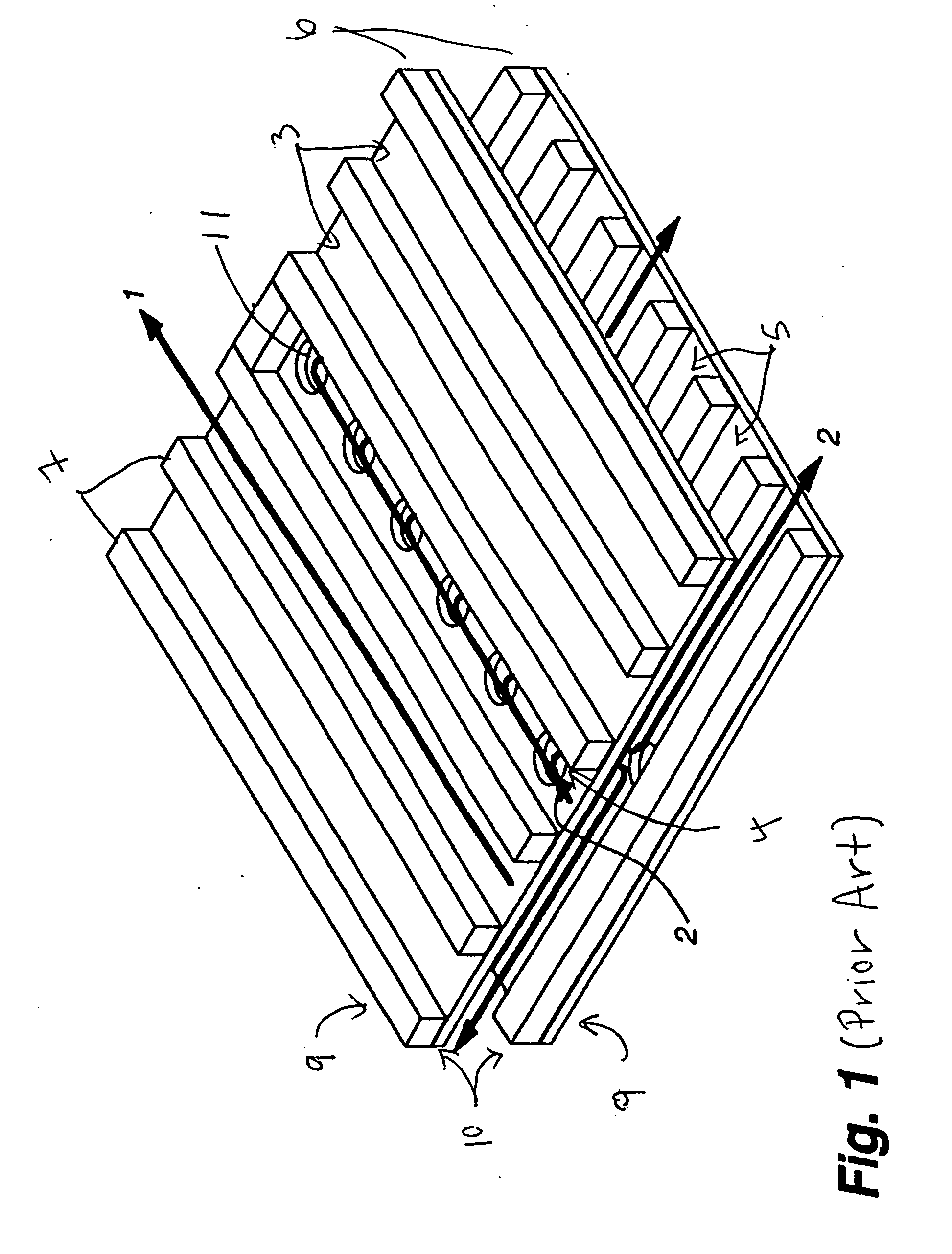

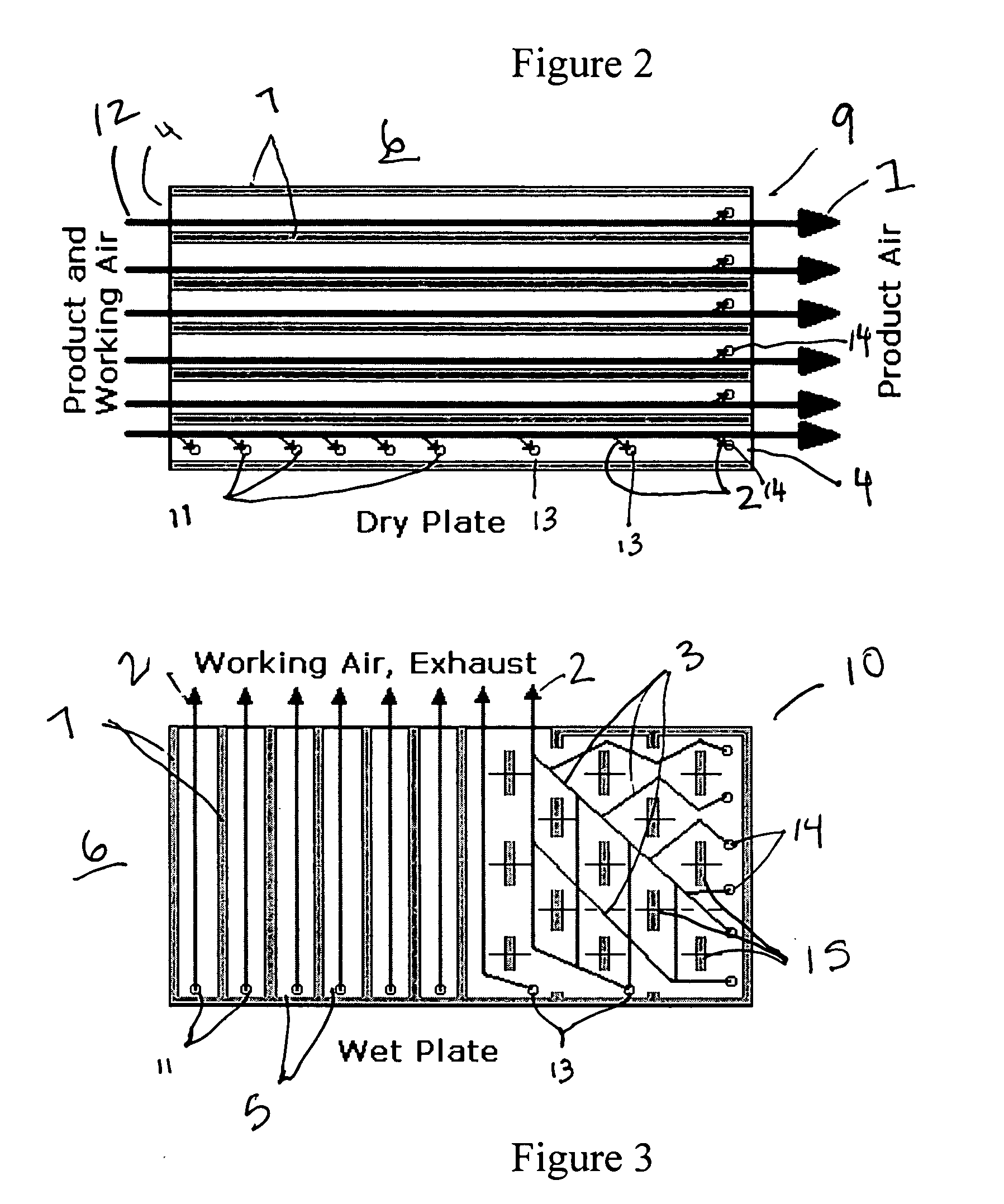

[0030]FIGS. 2-4 illustrate one embodiment of an indirect evaporative cooler wherein part of the product gas is used as working gas. Note that while the term “air” is frequently used in the following description, others types of gas may be used as well, so long as the same kind of gas is used for the product gas and the working gas. The following table lists reference numbers used in this patent:

1output product gas2output working gas3wet side paths4dry side channels5wet side channels6plates7channel guides8wick material9dry sides of plates10wet sides of plates11input end side perforations12Input common product and working air13output end side perforations14output end edge perforations15wet side path barriers

[0031]FIG. 2 is a plan view of the dry side 9 of a heat transfer plate 6 used in an evaporative cooler according to the present invention. Combined product and working air 12 enters dry side channels 4 from the left of the figure. Channels 4 are generally formed with a series of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com