Complex shaped fiber for particle and molecular filtration

a fiber and complex technology, applied in the field of filter system, can solve the problems of ineffective filtering out certain chemicals, short life span of conventional chemical filters, frequent replacement, etc., and achieve the effect of reducing contaminants and ultra-high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

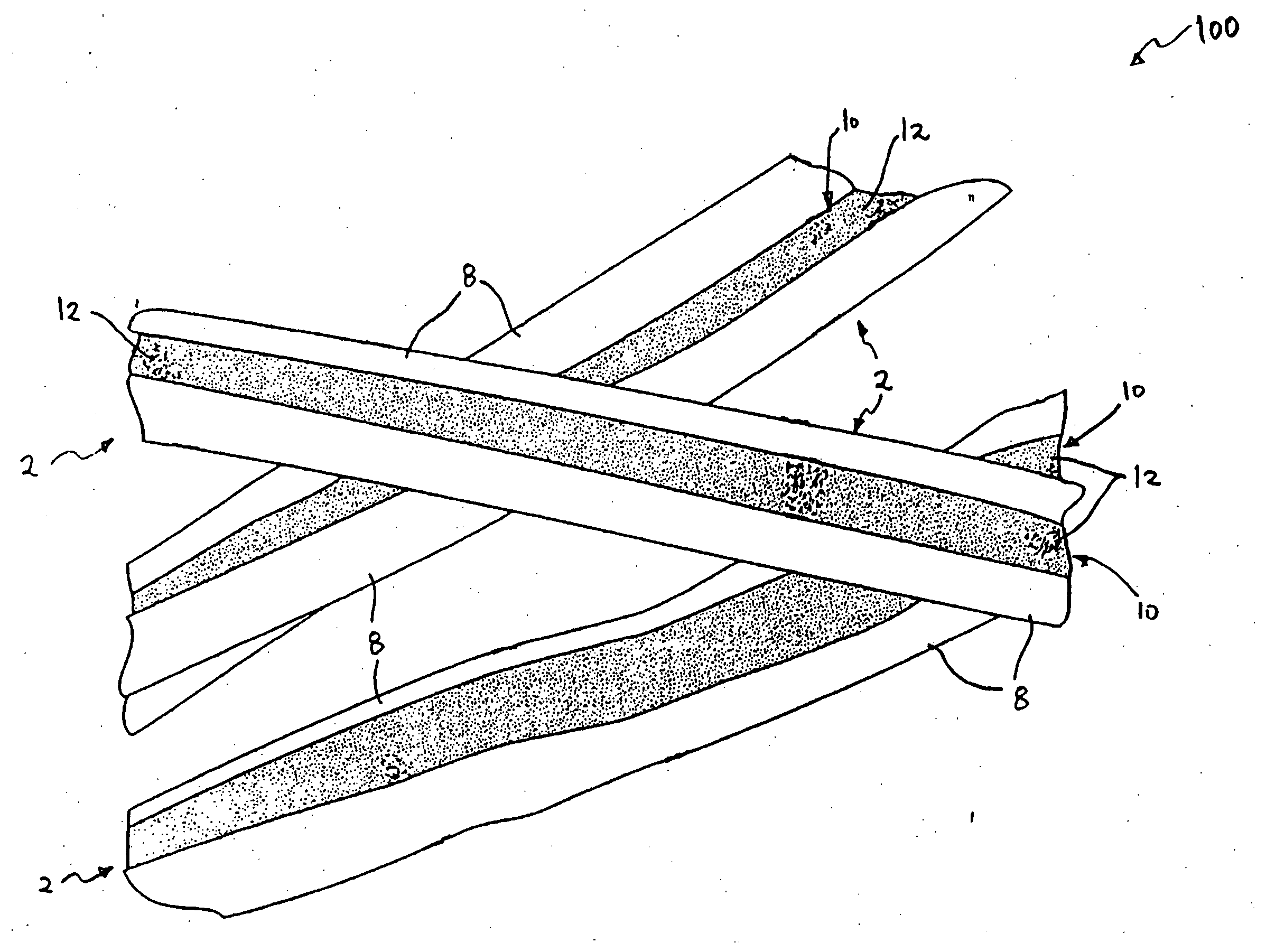

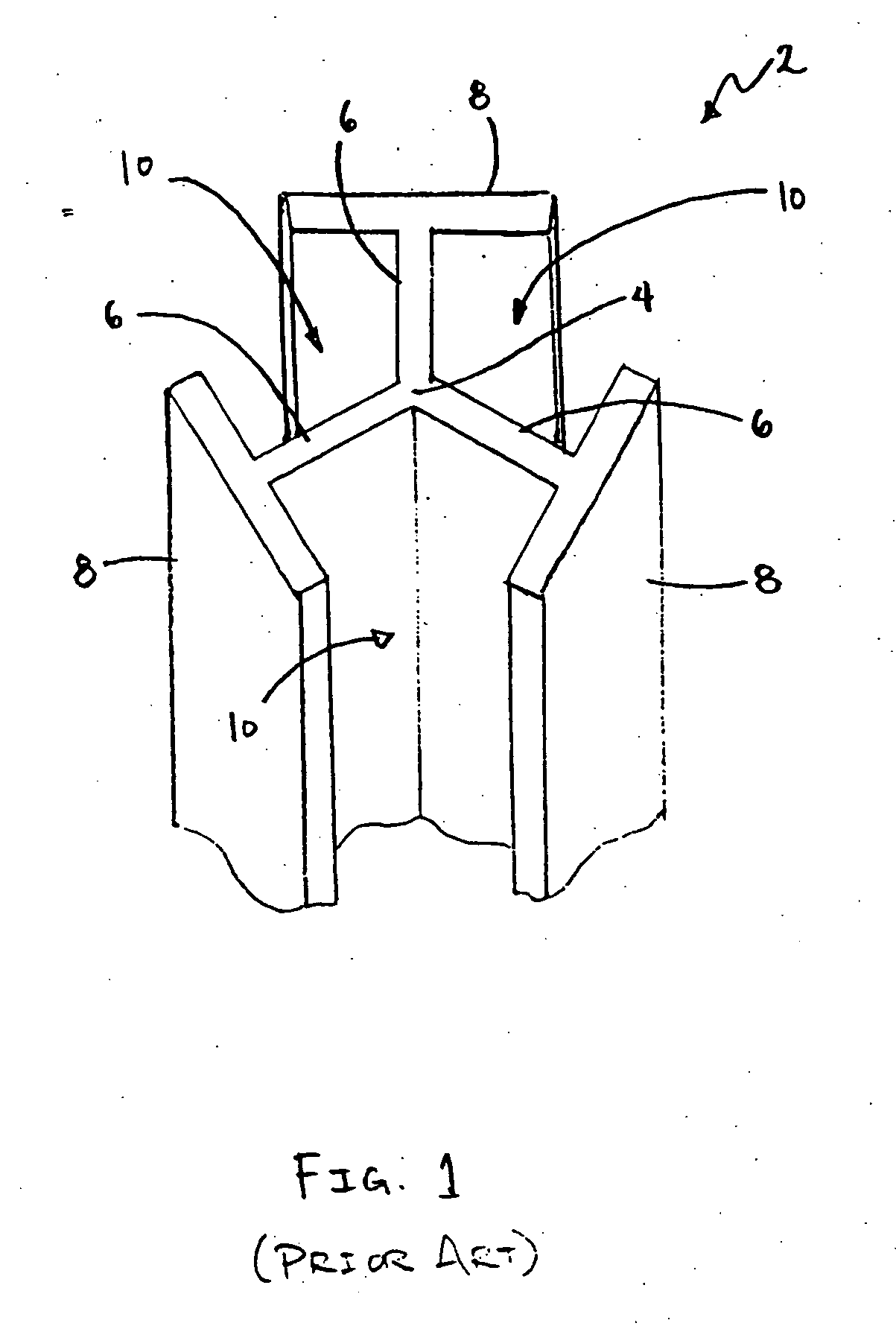

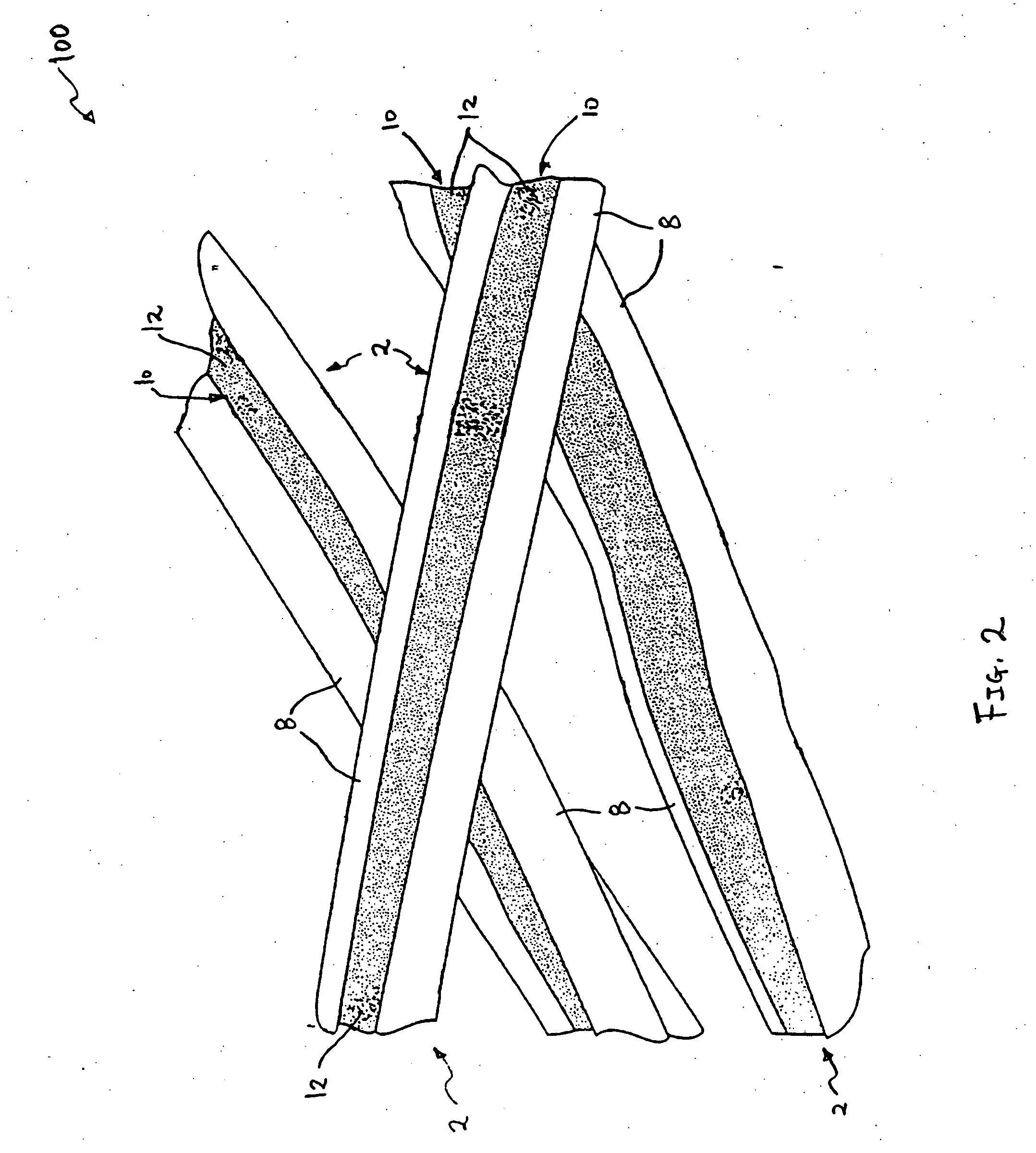

[0017]FIG. 1 shows a detailed view of a cross section of an individual multilobal fiber 2. Fiber 2 is a type of fiber made of thermoplastic polymers and formed by conventional fiber forming techniques, such as spinning a fiber composition through a conventional spinnerate, as described in the above-referenced U.S. Pat. No. 5,057,368. Fiber 2 includes a core 4, from which three lobes 6 extend outwardly. Each of lobes 6 terminates with a cap 8 which is perpendicularly attached to the end of lobe 6. The cavity formed between lobe 6 and adjacent caps 8 runs along the entire length of multilobal fiber 2 forming longitudinal slot 10. Multilobal fiber 2 has the ability to retain powdered particulate matter, such as powdered carbon. The carbon powder can be mechanically held within slot 10 entrapped by caps 8 without the use of any liquids. Entrapping the powder within slot 10 can be accomplished by dusting the powder into the fibers and then shaking off the excess powder or blowing the exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com