Dental matrix band seal in combination with a matrix band

a technology of dental matrix and matrix band, which is applied in the field of dental matrix band seal in combination with a matrix band, can solve the problems of cavity filling material deterioration, dampening or contaminating the surface of the tooth being filled, and current technology, so as to reduce or eliminate capillary action, and eliminate the ingress of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

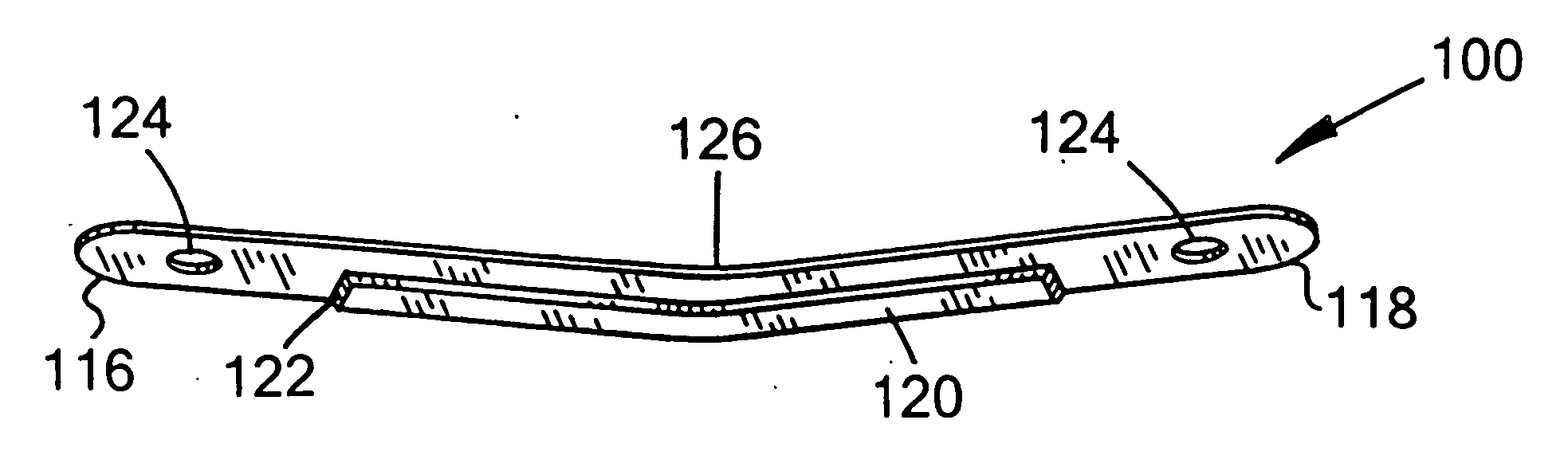

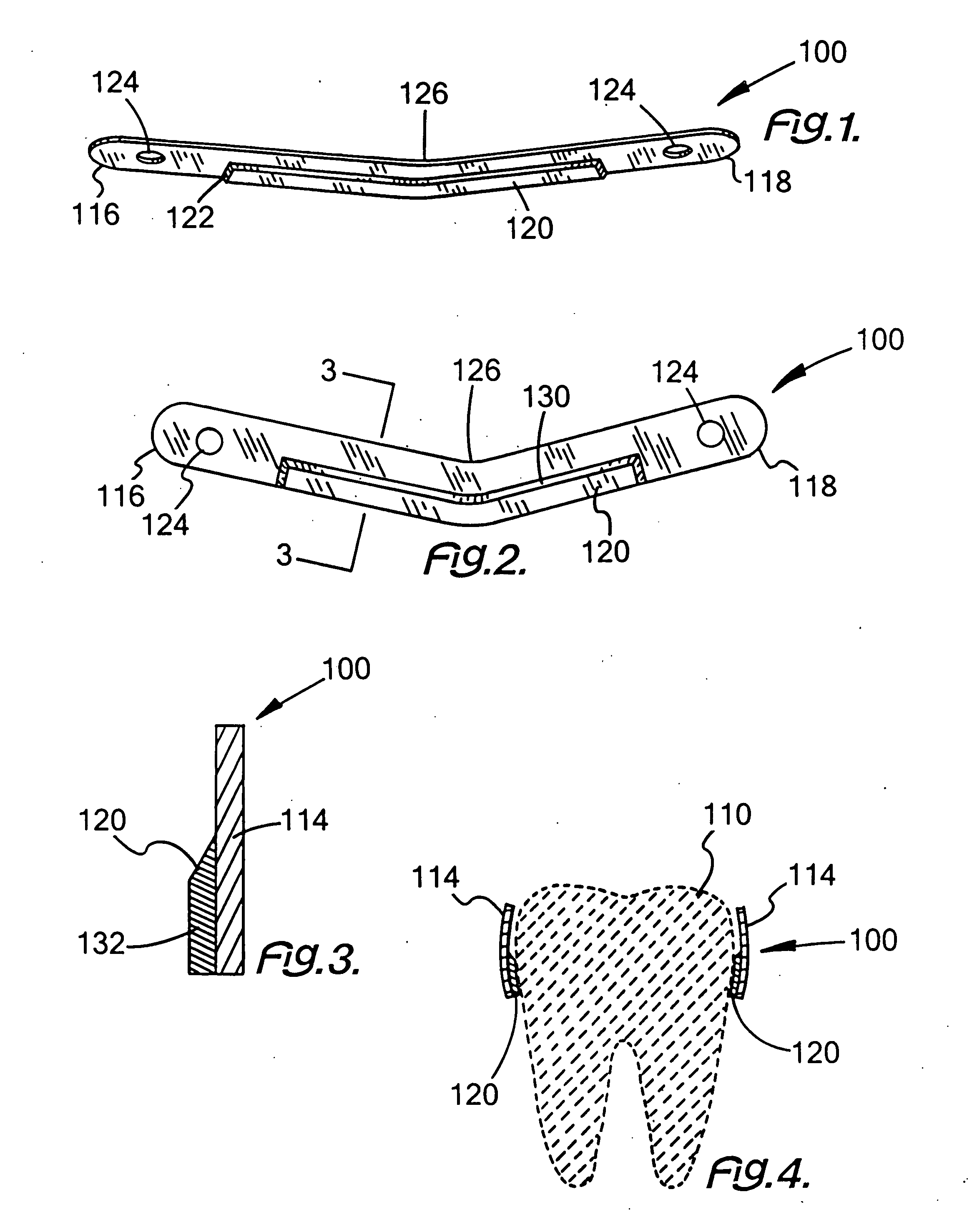

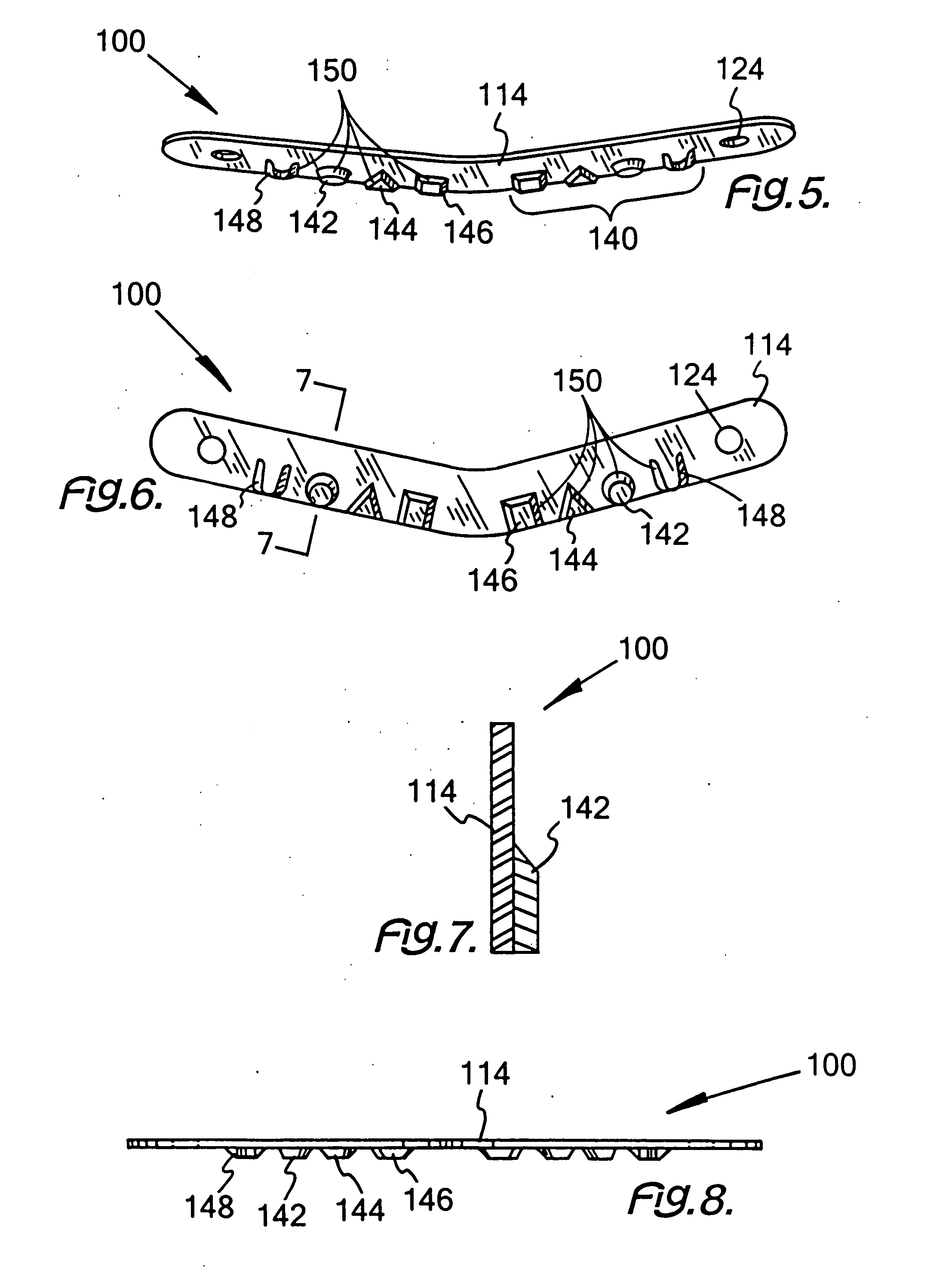

[0070] With the straight coated matrix band 100; having a strip polymer 120 is applied onto a stainless steel support base 114 etched in an acetic acidic solution having a pH of 5.5, the strip polymer 120 being based on a pharmaceutically acceptable siloxane polymer. That straight coated matrix band 100 is applied to a tooth 110 under repair, where the coating provided a seal that prevented the ingress of fluid into the area of the tooth being repaired.

example two

[0071] The procedure of Example One is repeated except that the etching solution is phosphoric acid and has a pH of 5.0. The coating adheres as well as in Example One.

example three

[0072] The procedure of Example One is repeated except that the etching solution has a pH of 4.7. The coating adheres adequately but is not as durable as the coating set forth in Example Two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com