Pillow

a technology of pillow and sleeve, which is applied in the field of pillow, can solve the problems of deterioration of comfort during sleep and instability at the head region, and achieve the effects of reducing heat conduction efficiency, preventing latent heat storage medium, and imposing no strain on the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

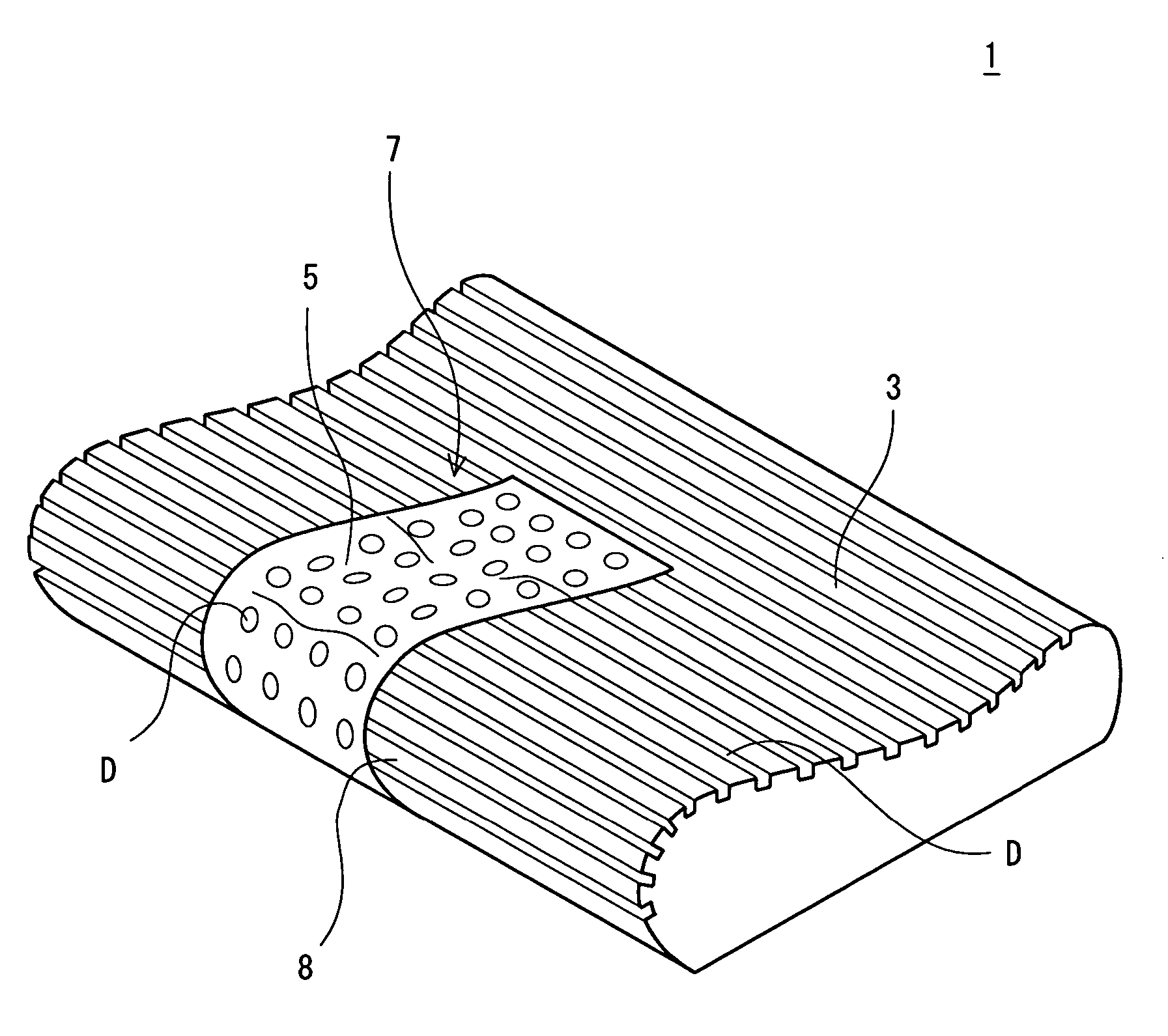

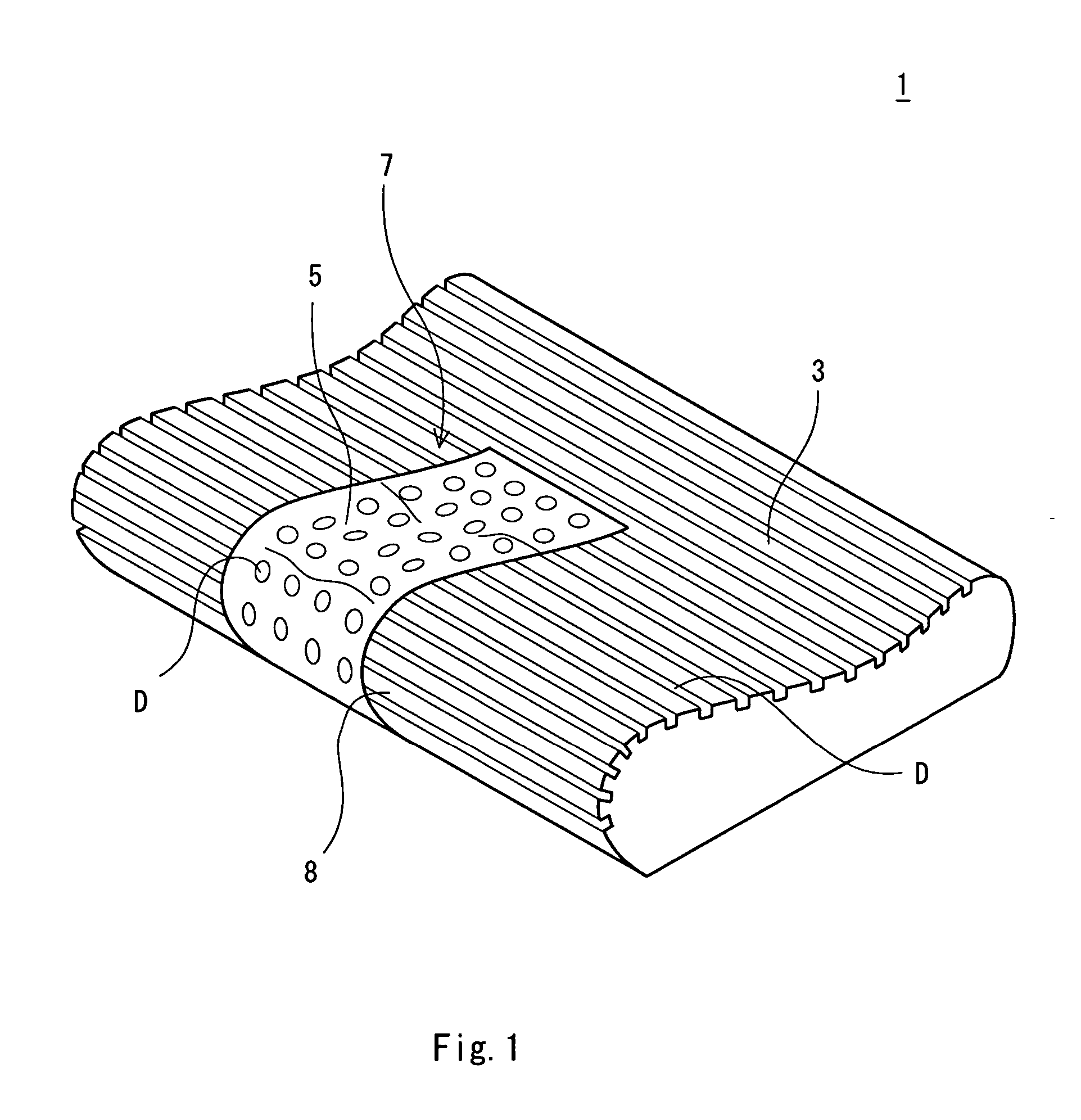

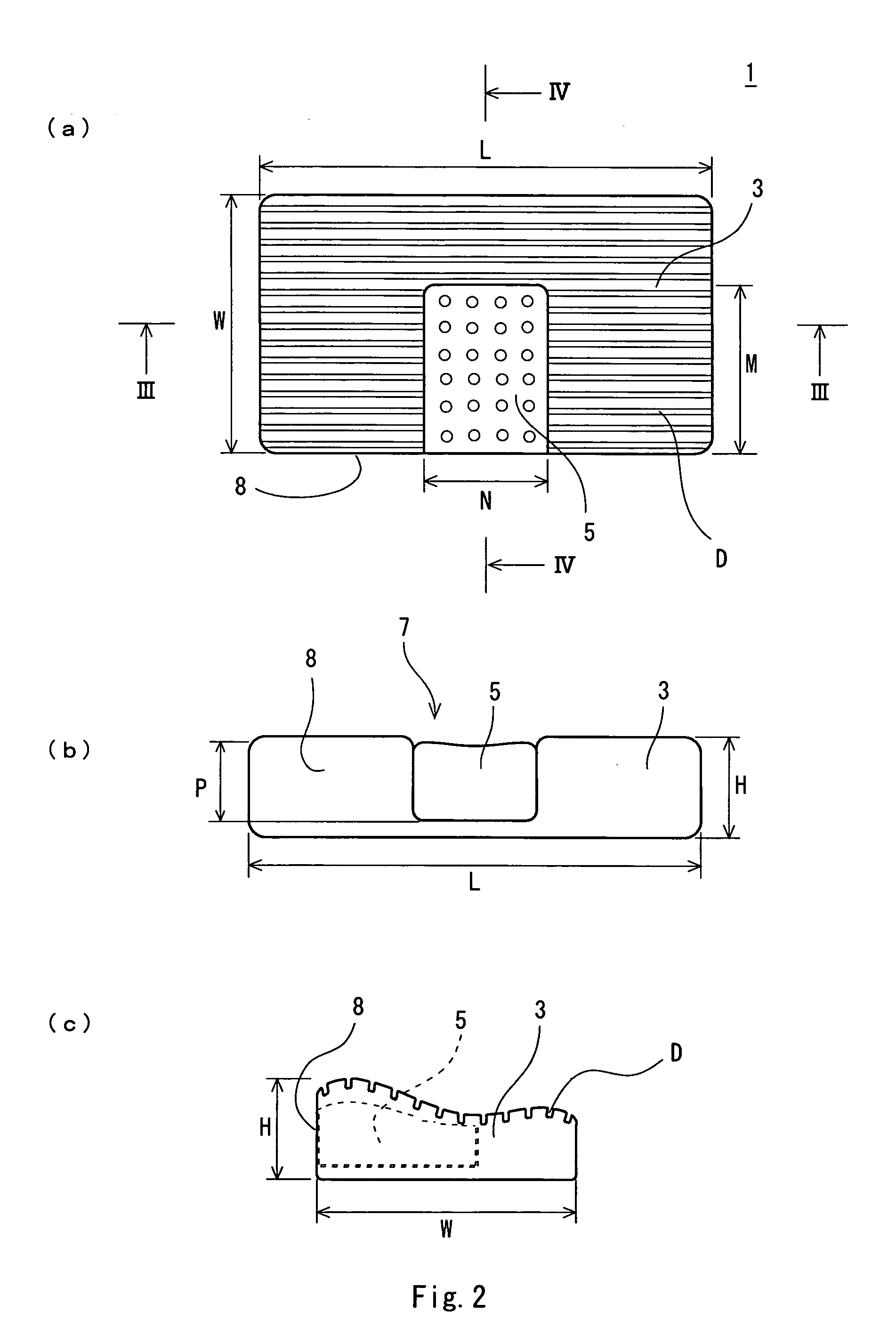

Image

Examples

example 1

[0077] A rubber composition containing a natural rubber as a base (100 parts by weight of a natural rubber, 115 parts by weight of a filler, 4 parts by weight of a softening agent, 5.5 parts by weight of zinc white, 1.1 parts by weight of stearic acid, 5 parts by weight a foaming agent, 2 parts by weight of sulfur, 0.9 part by weight of a vulcanization accelerator, 0.6 part by weight of an antiaging agent) was placed into a mold, and allowed to be vulcanized and expanded at 150° C. for 10 minutes to perfect forming. Accordingly, a main body having a concave portion was manufactured. On the other hand, a polyurethane film (thickness: 0.1 mm, tensile strength: 20 N, tear strength: 8 N, elongation at break: 220%) was laid on a mold having a shape corresponding to the shape of the concave portion of the main body, and then, a polyurethane prepolymer prepared by compounding and dispersing 10% by weight of microcapsules containing a latent heat storage medium (powder form) was cast into t...

examples 2 to 13

[0079] A cold insulator was produced similarly to Example 1 except that the melting point of n-paraffin as a latent heat storage medium, -or the amount of the microcapsule containing the latent heat storage medium was altered. This cold insulator was combined with the main body to obtain pillows of Examples 2 to 13. The cold insulator in Examples 5 and 6 is in a sheet form, which cold insulator obtained by filling microcapsules containing the above-mentioned polyurethane prepolymer and latent heat storage medium in a pouched sheet, without filling the polyurethane composition to be cured.

[Evaluation Test of Pillow]

[0080] (1) Determination of Temperature Change

[0081] The cold insulators of the above-mentioned Examples and Comparative Example were left to stand in a refrigerator (temperature inside: 5° C.) for 8 hours or longer, and thus, the internal temperature of the gel material was regulated to be 5° C. Next, an adult male whose body temperature was approximately 36° C. lay th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com