Barrier-protected container

a container and barrier technology, applied in the direction of axle-box lubrication, railway components, railway bodies, etc., can solve the problems of difficult or impossible to arrange reinforcement in the concrete in optimal configuration, extremely heavy encased structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004] The present invention aims to provide an alternative type of blast and / or ballistic resistant structure which is more convenient, more reliable and lighter than concrete encased freight containers.

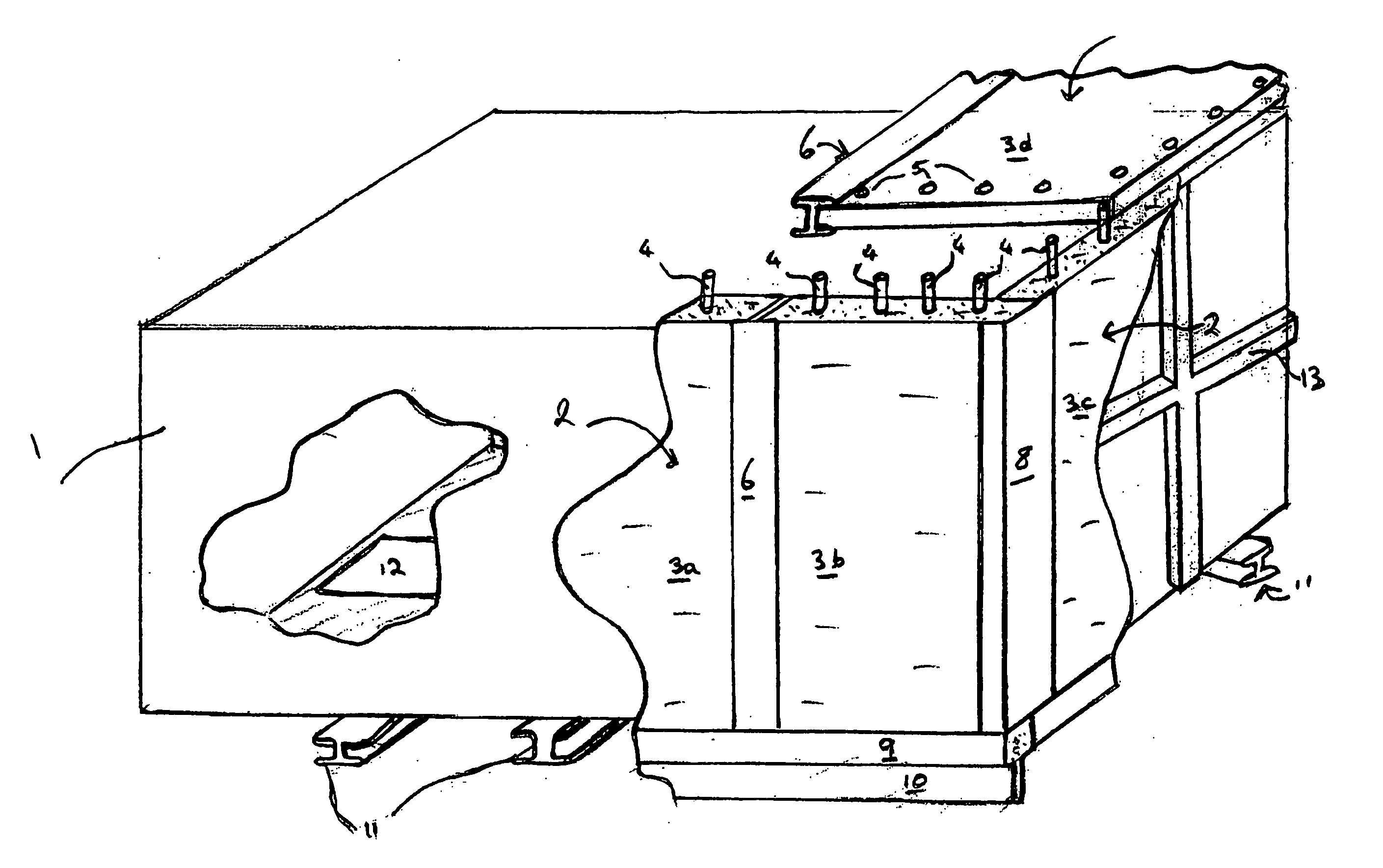

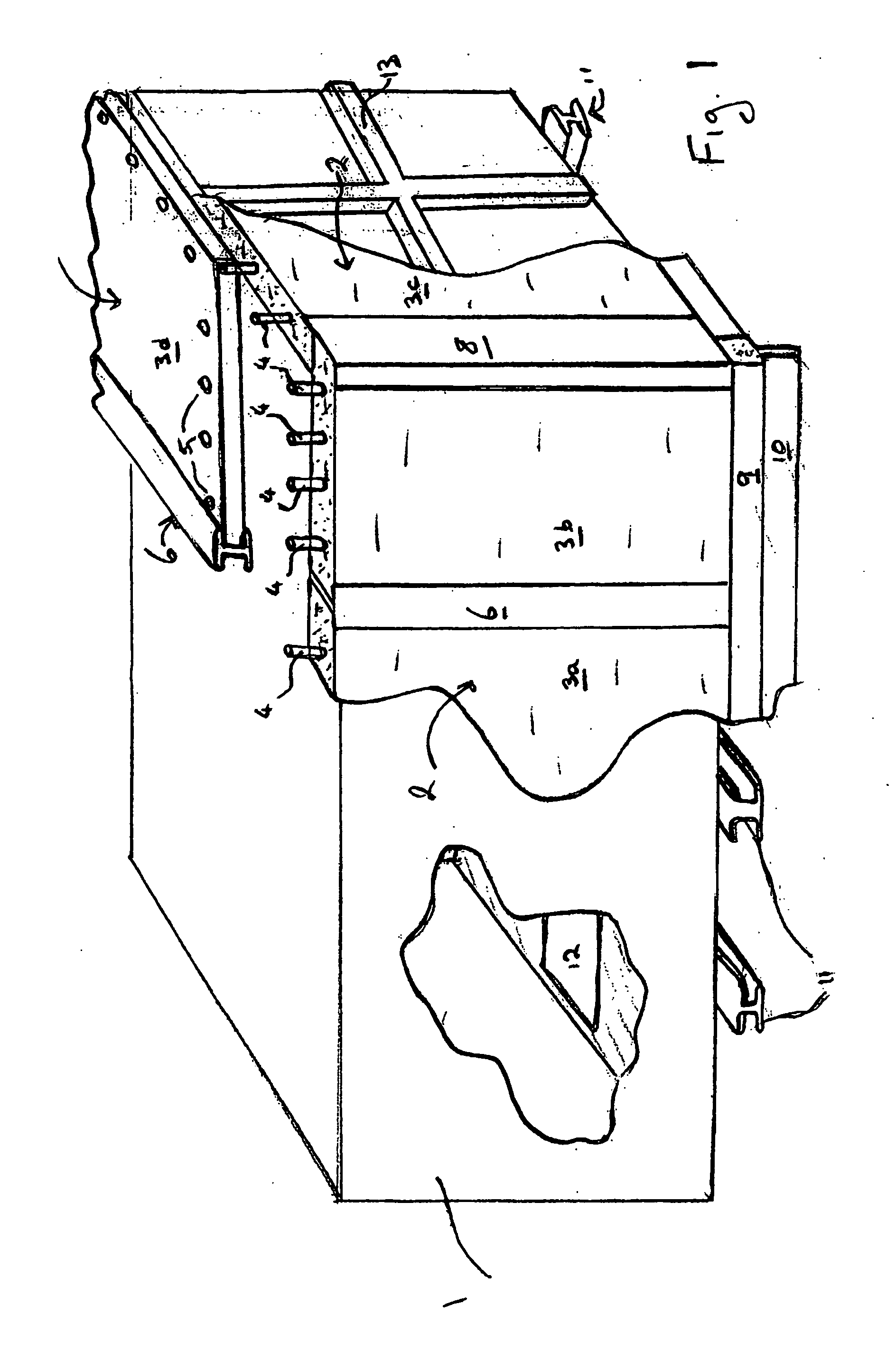

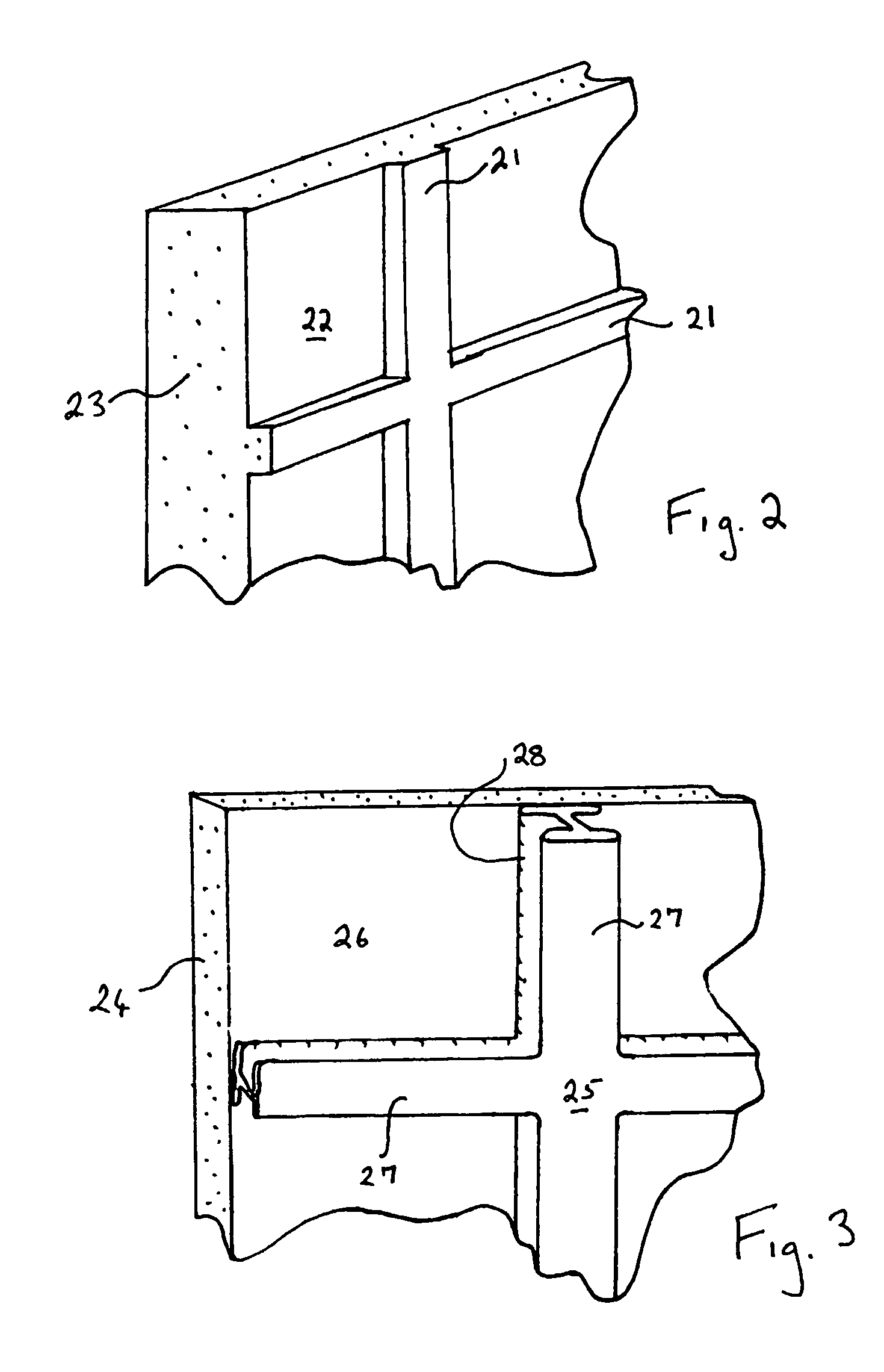

[0005] According to the invention, there is provided a structure comprising a walled freight container enclosing an interior volume of space, the container being at least partially clad internally and / or externally with a barrier structure, the barrier structure comprising a single panel or a plurality of panels of matrix material incorporating reinforcement elements, and means for human entry into and exit from the interior space of the container being located in a wall of the container and, if necessary for such entry and exit, also in the barrier structure.

[0006] As used herein, the terms “walled freight container” or freight container” or “shipping container” or “transport container” all refer to the reusable articles of transport equipment in common use for transporting goods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com