Leak resistant lid assembly for a beverage container

a beverage container and lid technology, applied in the field of leak-resistant lids for containers or cups, can solve the problems of affecting the leakage rate of liquids, the tendency of liquids to leak out of the lid in the rim area, and the approach is not entirely successful, so as to achieve the effect of high leakage resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

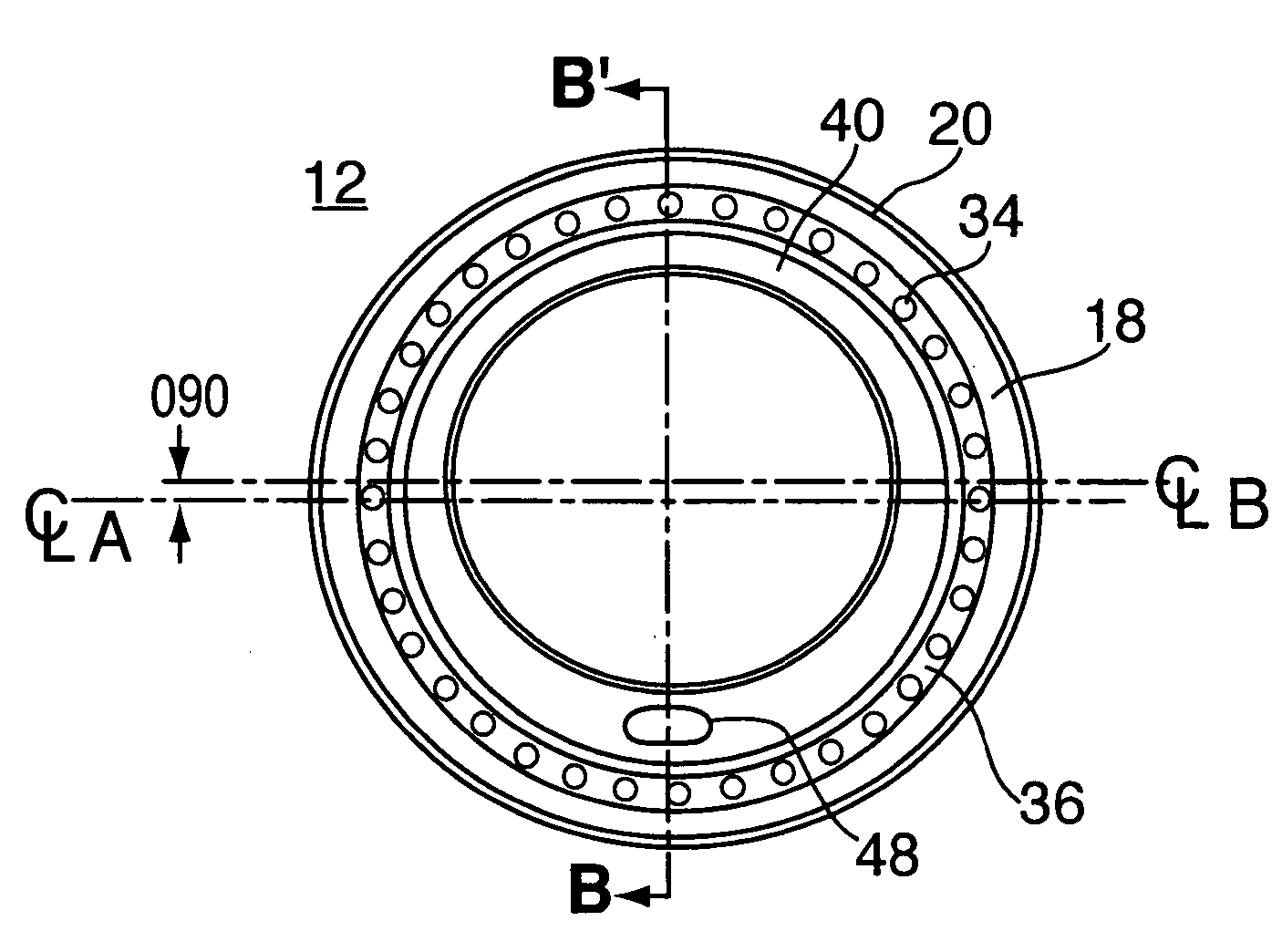

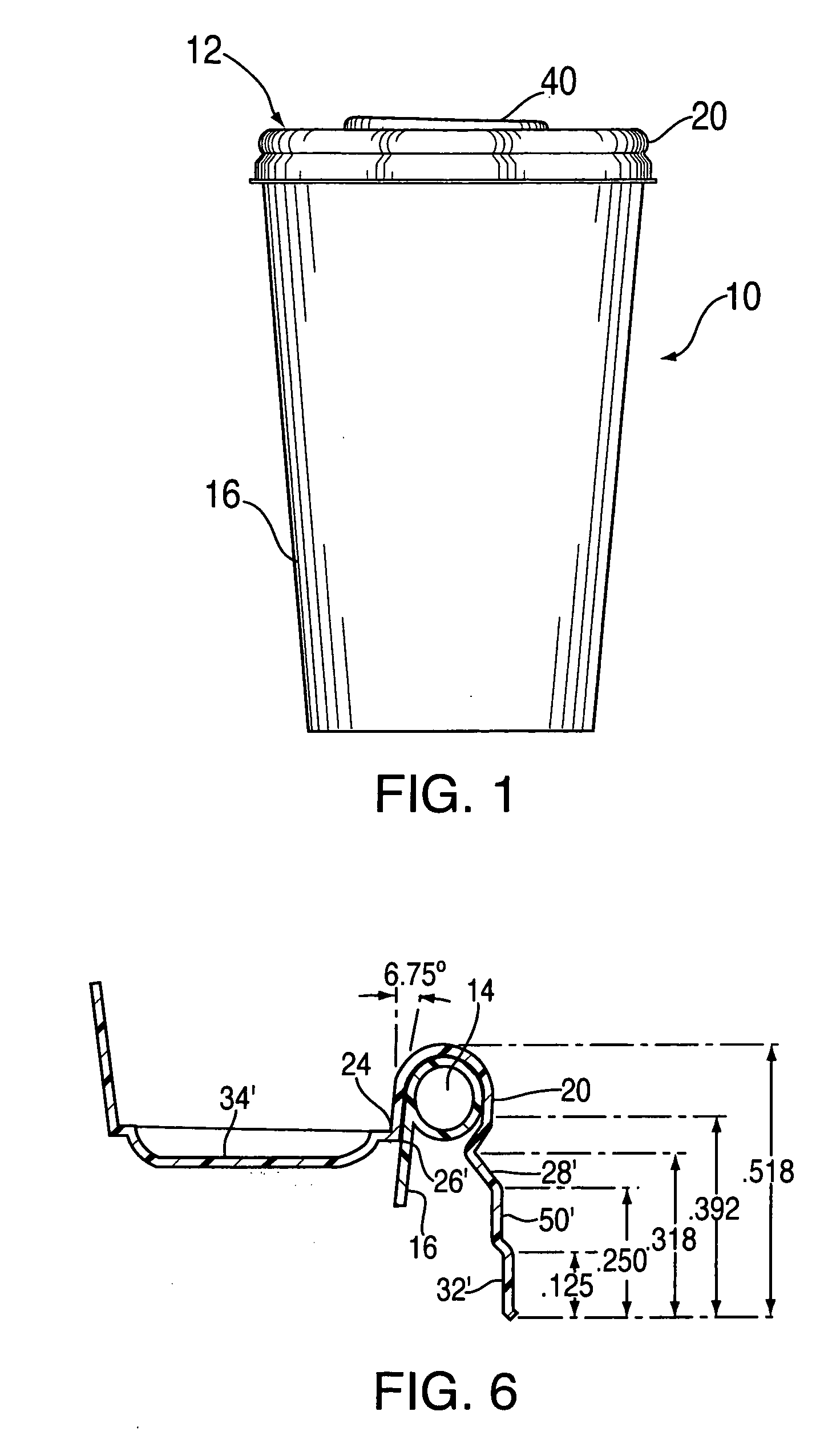

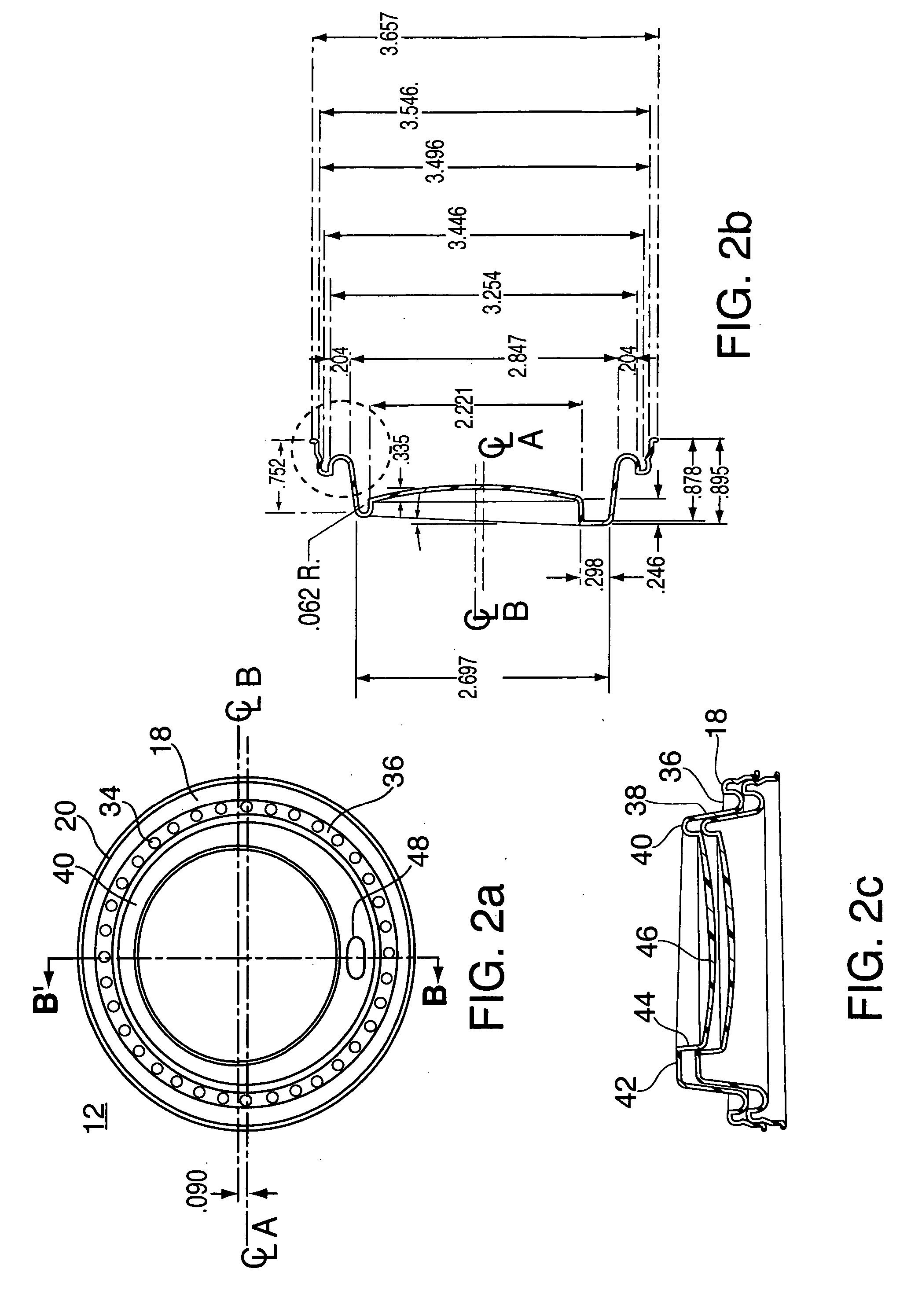

[0018] Referring to FIG. 1, a typical container or cup assembly 10 suitable for beverages and being formed from paper, plastic, plastic foam or the like, in a generally cylindrical or frusto-conical shape, is shown. A lid 12 constructed according to the present invention is shown sealably mounted at the top of container 10. Lid 12 (other forms of which are shown in greater detail in others of the figures) preferably is produced by thermoforming a thin, flat sheet of clear or opaque (black, white or colored) plastic such as polystyrene onto a lid mold to form the desired lid shape which will be explained below. The lid may also be formed by injection molding while maintaining the desired properties and characteristics as set forth hereinafter. The thickness of the plastic for the lid typically is about 0. 017 inches in its finished form.

[0019] The container 10 typically is a paper cup suitable for hot or cold beverages and will be referred to hereinafter as cup 10. As is customary, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com