Motor frame cooling with hot liquid refrigerant and internal liquid

a technology of hot liquid refrigerant and motor frame, which is applied in the direction of refrigeration components, lighting and heating apparatus, domestic cooling apparatus, etc., can solve the problem that single-phase cooling cannot be completely removed, and achieve the effect of enhancing both the two-phase and the single-phase heat transfer arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

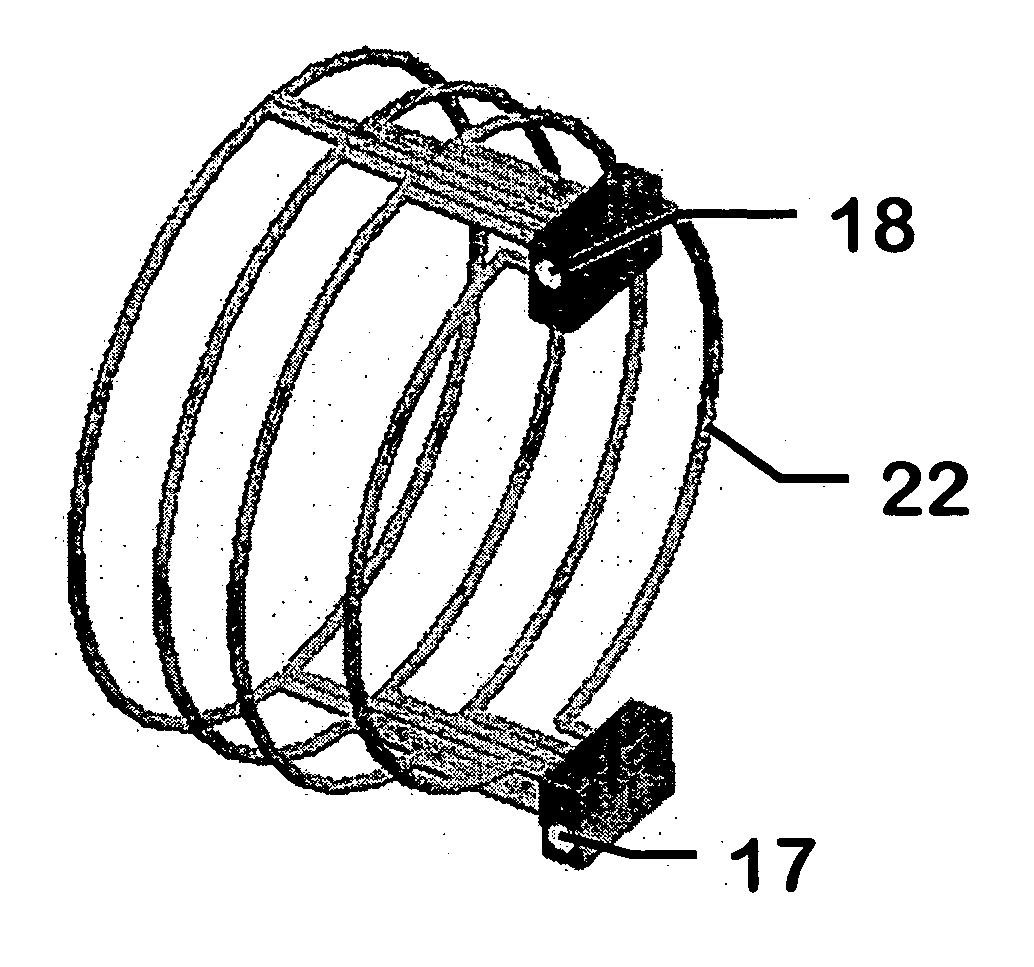

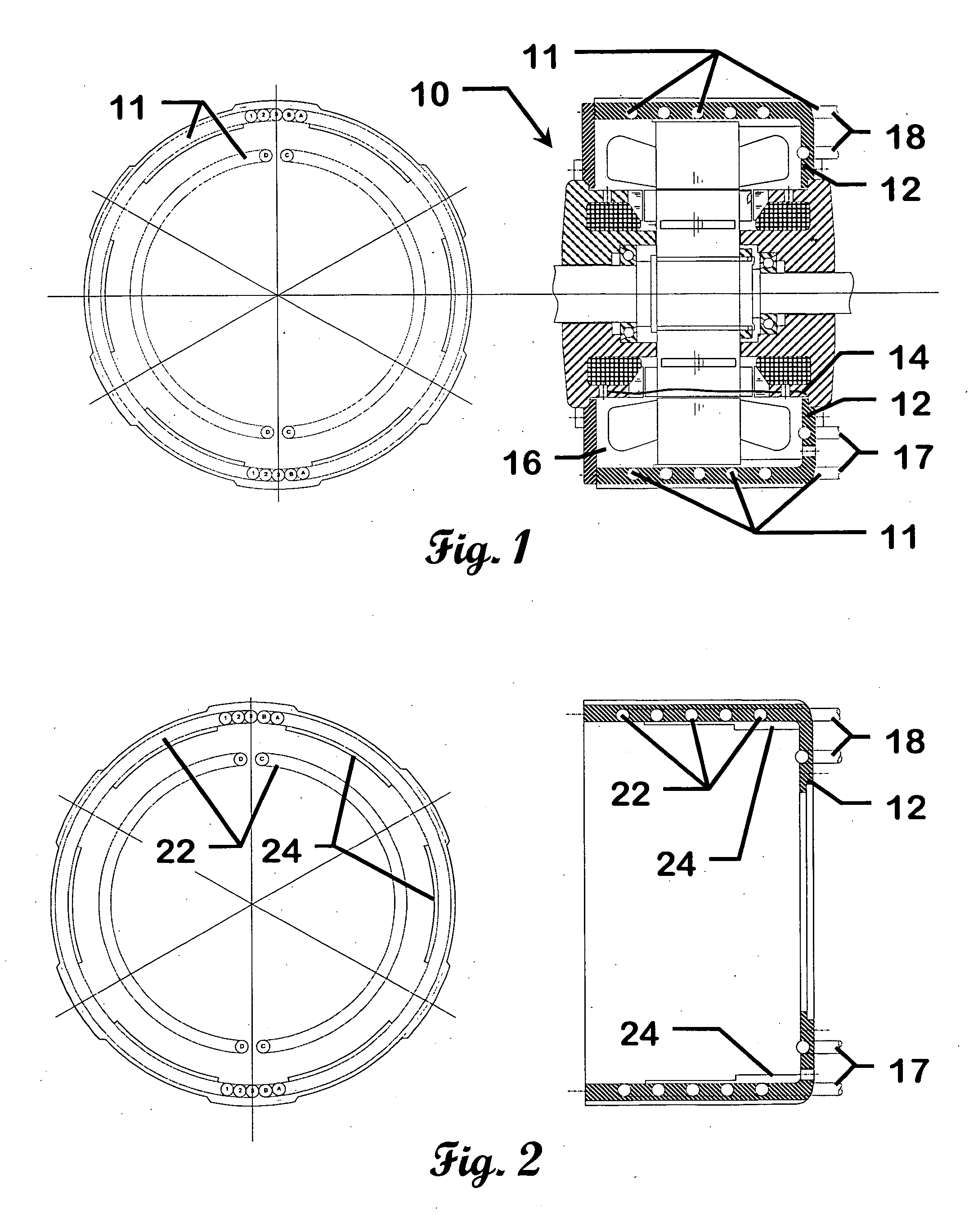

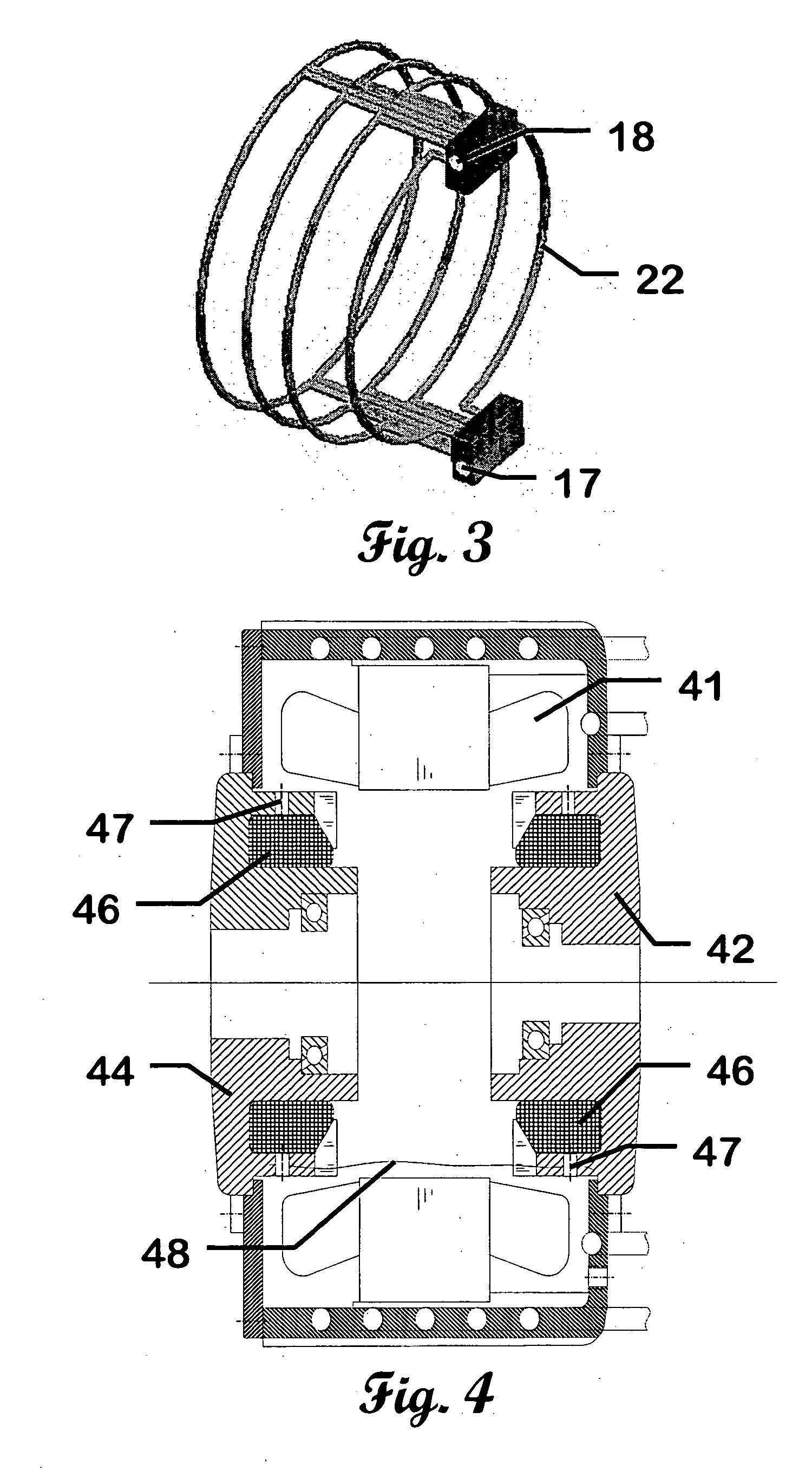

[0018]FIG. 1 shows an embodiment of the invention using tubes 11 cast in a frame 12 and internal liquid level 14 inside electric machine 10 for combined two-phase and single-phase cooling. Metal tubes withstand the high pressures required by the hot liquid refrigerant flowing in the frame 12. An internal liquid 16 such as a transmission or lubrication oil is filled at the bottom of the frame 12. Hot liquid refrigerant 17 enters the electric machine 10 from a floating refrigerant loop (not shown) as described in co-pending U.S. patent application No. 60 / 565,461 filed Apr. 26, 2004, herein incorporated by reference, and hot vapor refrigerant 18 exits the electric machine 10 returning to the floating refrigerant loop. The hot vapor refrigerant 18 that exits the electric machine 10 can be a mixture of refrigerant vapor and liquid depending on the heat load imposed by the electric machine. The floating refrigerant loop can be a stand-alone loop having a dedicated pump and condenser. Or, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com