Suspension component having localized material strengthening

a stabilizer bar and component technology, applied in the direction of resilient suspensions, interconnection systems, suspensions, etc., can solve the problems of unneeded process costs, heavy stabilizer bars, and rubber bushings that dampen the movement of stabilizer bars, and achieve good ductility and easy heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

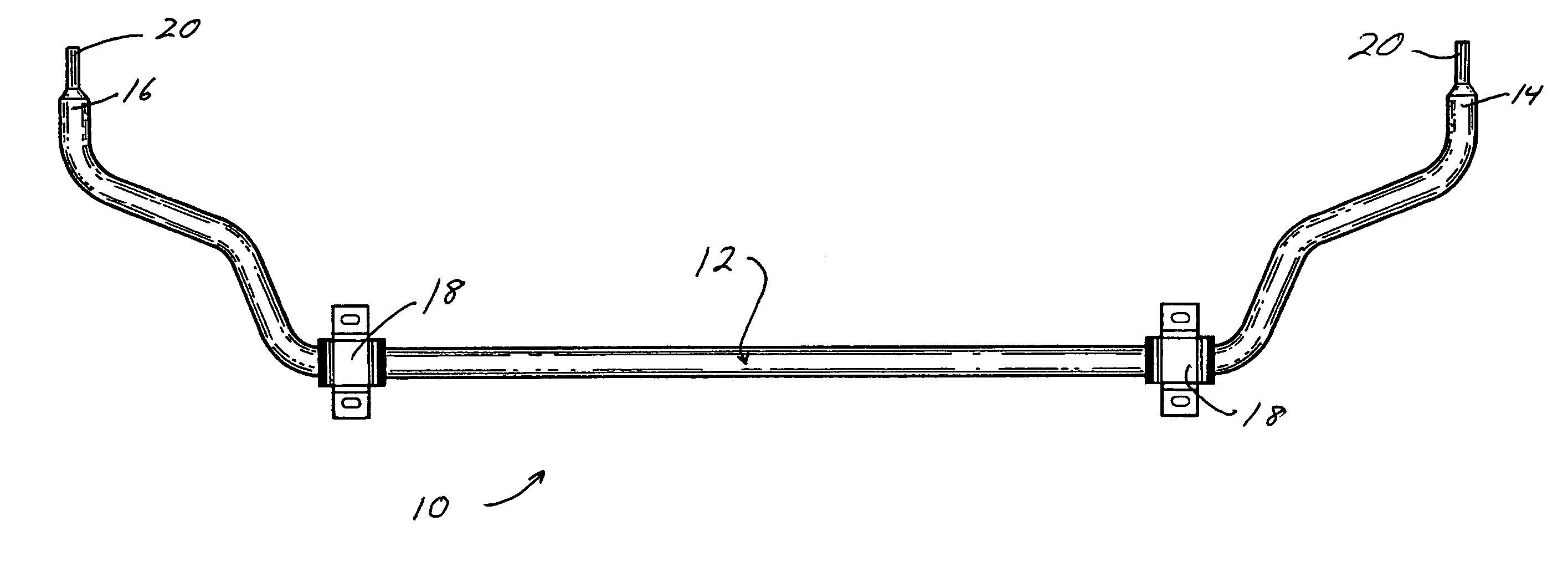

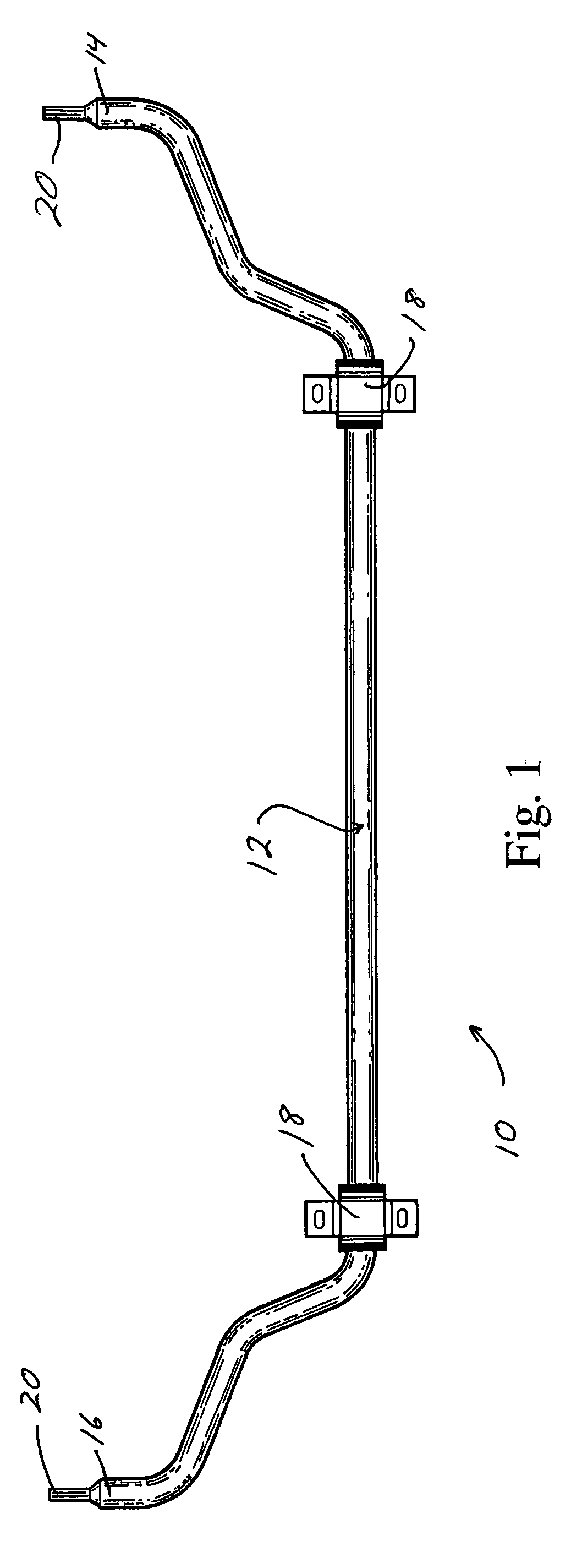

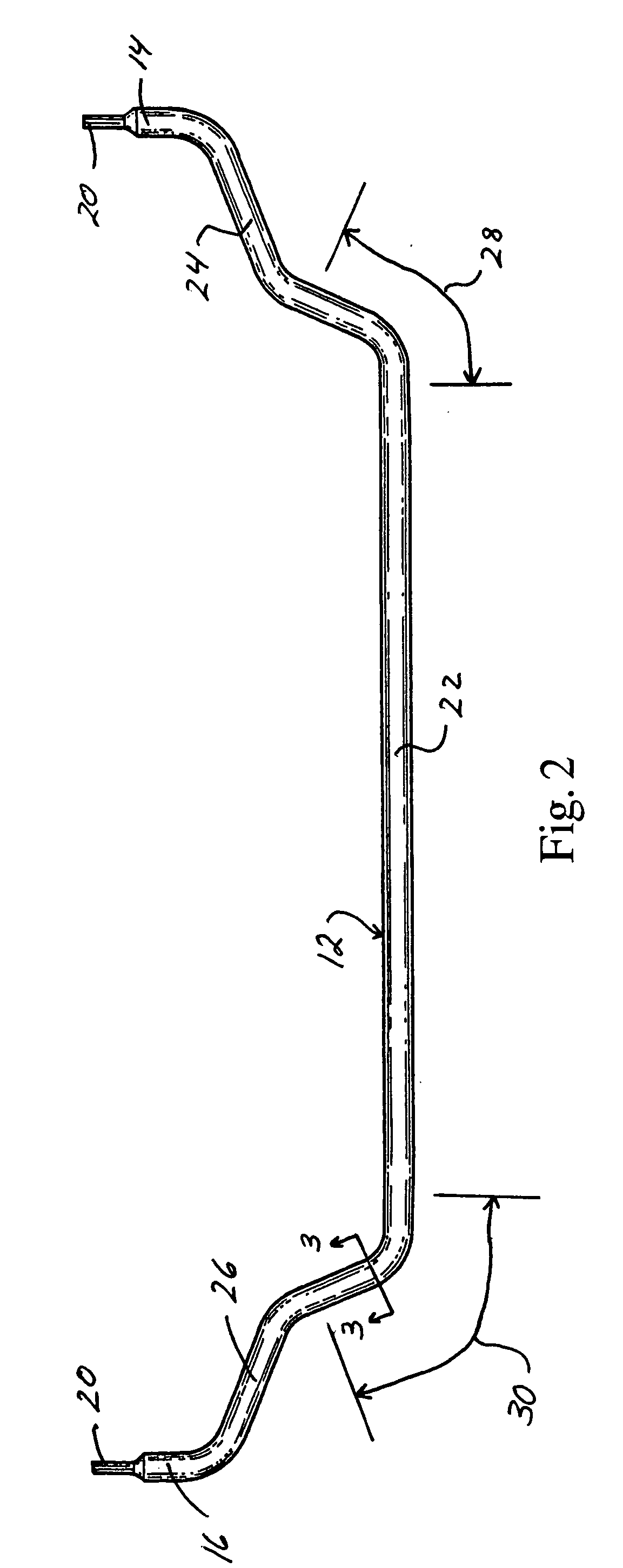

[0022] Referring to FIG. 1, a suspension component for an automotive vehicle is shown generally at 10. The suspension component shown is a stabilizer bar, however, it is to be understood, that the teachings of the present invention are applicable to other suspension components. The stabilizer bar assembly 10 includes a stabilizer bar 12 having opposing first and second distal ends 14, 16. The stabilizer bar 12 is generally made from steel, and can be solid or hollow between the ends 14, 16. The stabilizer bar 12 further includes at least one bushing assembly 18 mounted thereon. The bushing assemblies 18 are adapted to mount the stabilizer bar 12 to the structure of the automobile.

[0023] Each of the first and second distal ends 14, 16 have an attachment point 20. The attachment points 20 are adapted to connect the distal ends 14,16 to wheel assemblies (not shown) on the automobile. The attachment points 20 can be attached to the distal ends 14, 16, by welding. Alternatively, the att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com