Heat dissipation module with noise reduction

a heat dissipation module and noise reduction technology, applied in the direction of liquid fuel engines, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of heat dissipation design hitting a bottleneck, heat convection and heat dissipation design insufficient space inside the case housing of notebook pc, etc., to achieve the effect of reducing nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

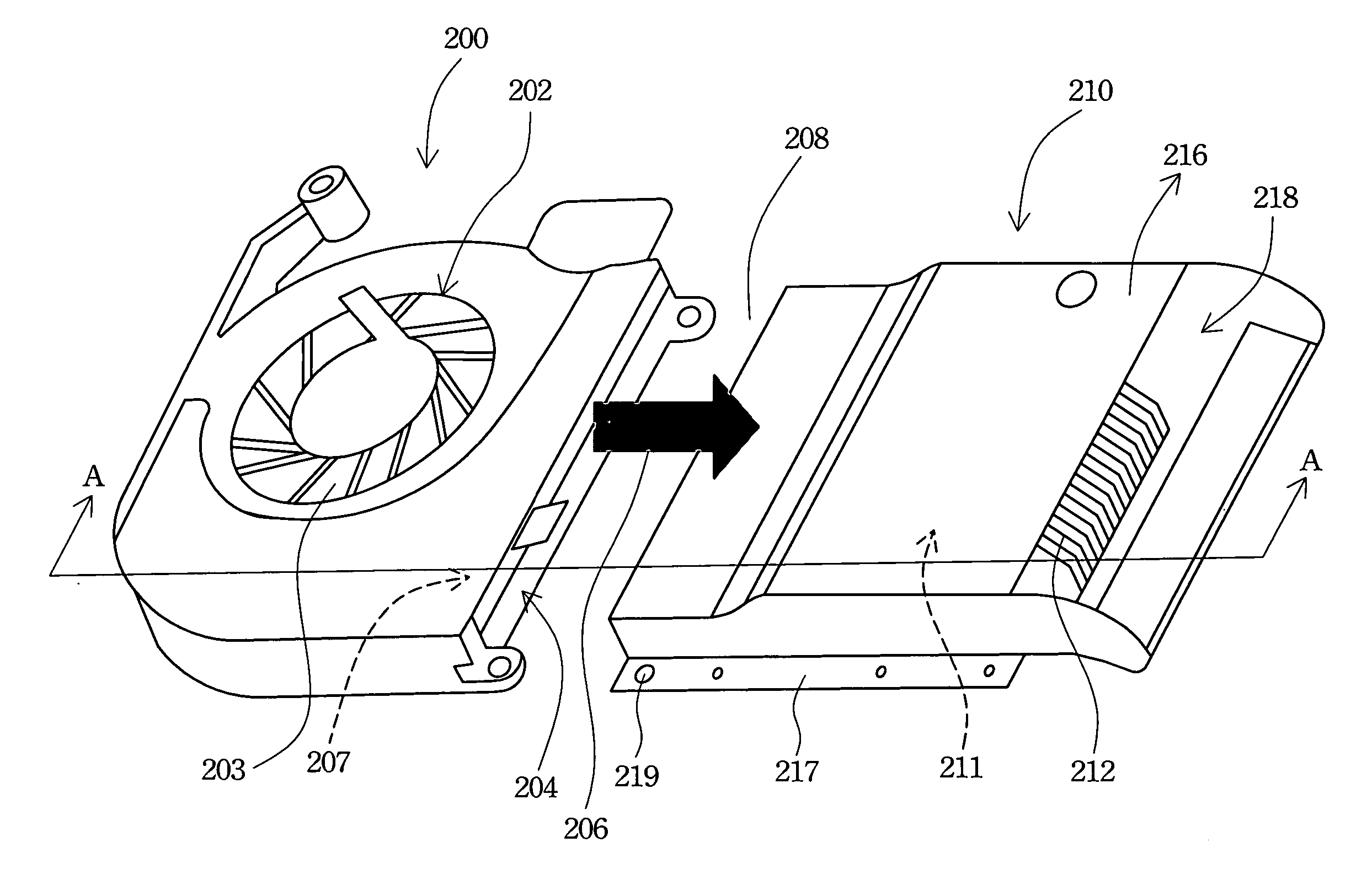

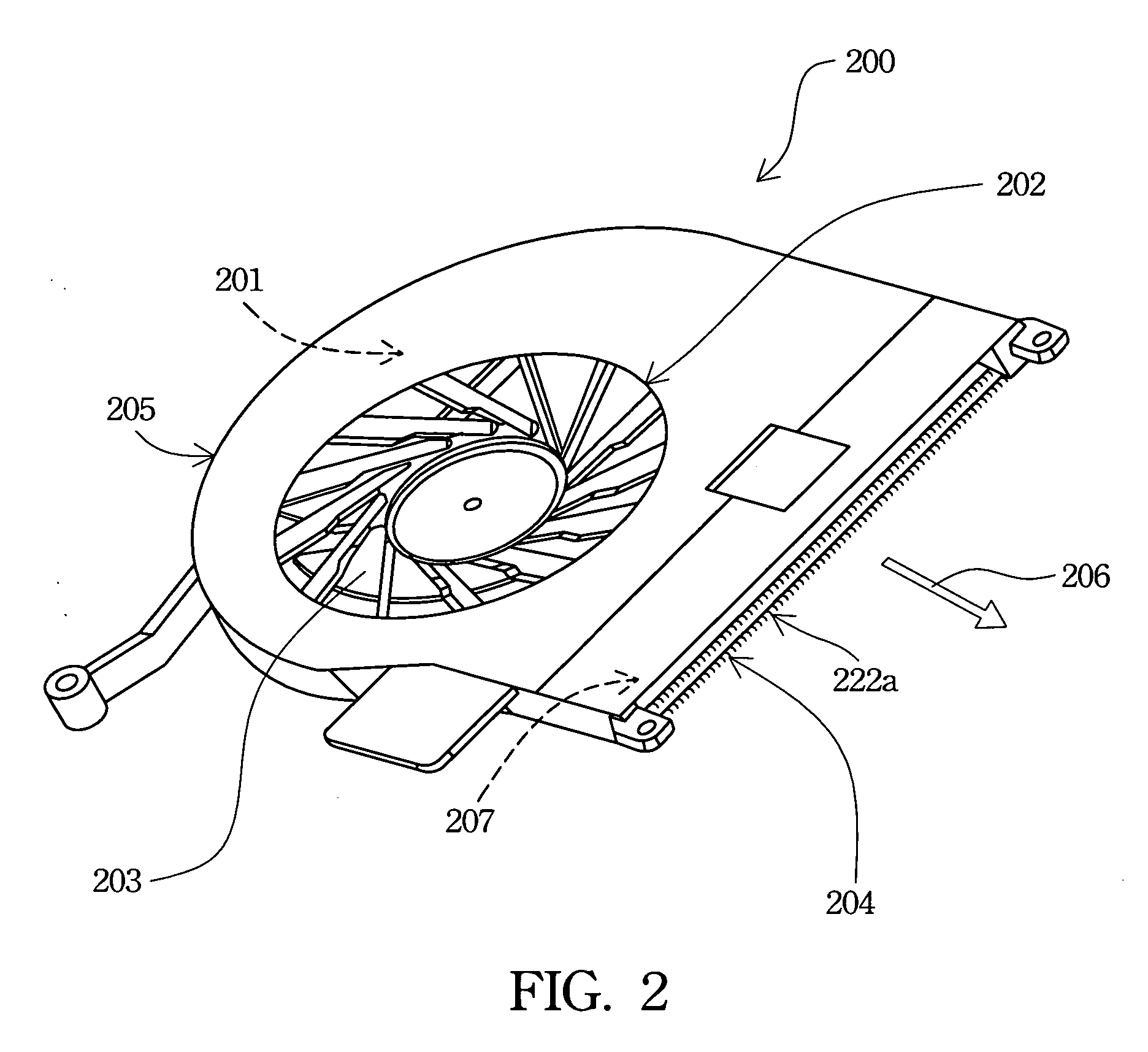

[0018] In order to reduce noise caused by strong airflow, the present invention discloses a heat dissipation module with a noise reduction function. By attaching a hair structure to an inner sidewall of a centrifugal fan's outlet, noise can be reduced. The hair structure can also be attached on an inner sidewall of a flow channel, such as a dissipation fin set, to reduce noise.

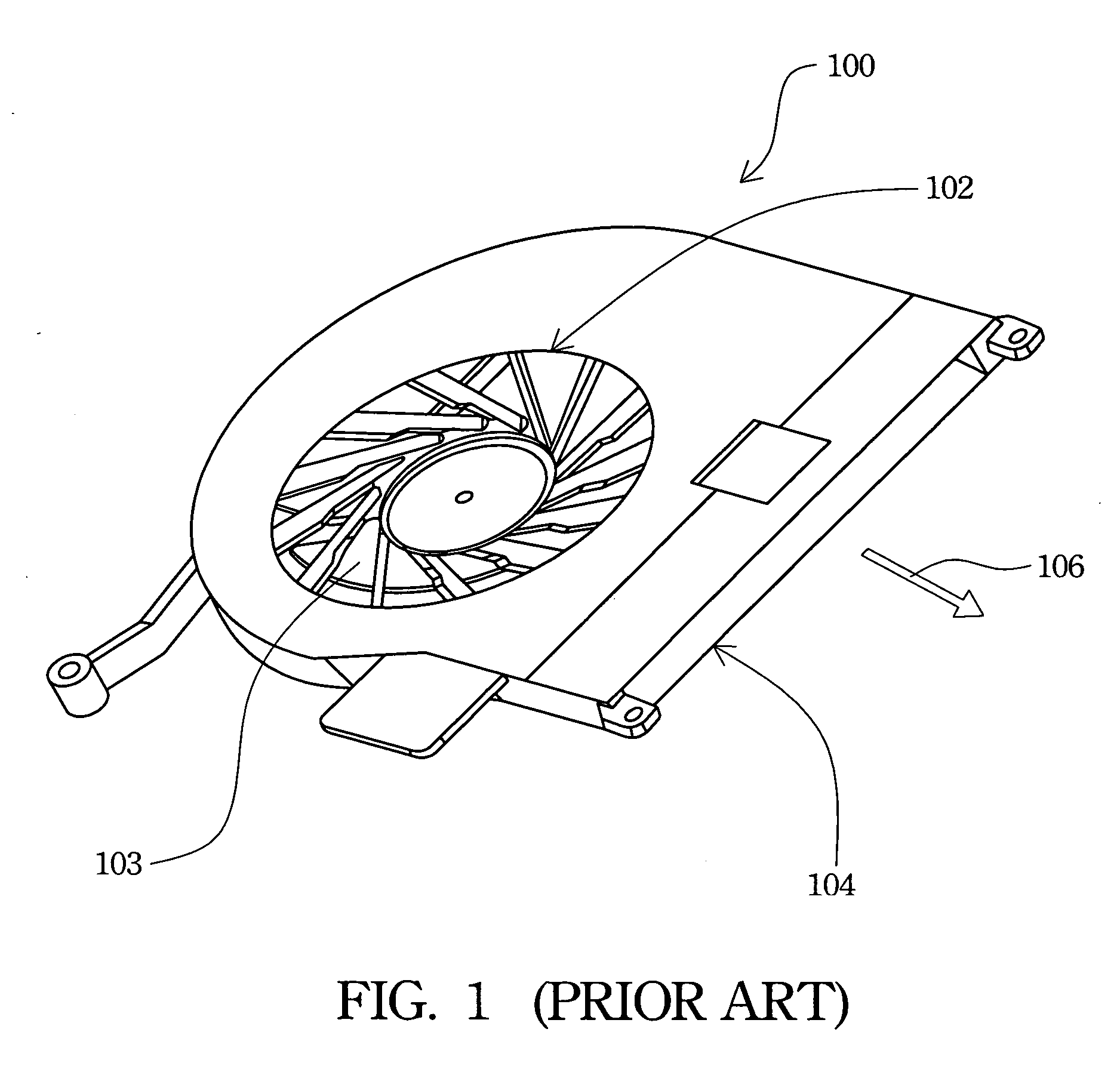

[0019]FIG. 2 illustrates a perspective view of a centrifugal fan with a noise reduction function according to one preferred embodiment of this invention. A centrifugal fan 200 includes a centrifugal impeller 203. A motor (not illustrated in FIG. 2) in the centrifugal fan 200 rotates the centrifugal impeller 203 to input air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com