Modular floor terminal with damper

a module and floor terminal technology, applied in the field of module floor terminals, can solve the problems of unpredictable and uncontrollable performance, difficult to predict the effect of air current in the plenum, and difficult to plug and play installation, and achieve the effect of convenient and easy plug and play installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

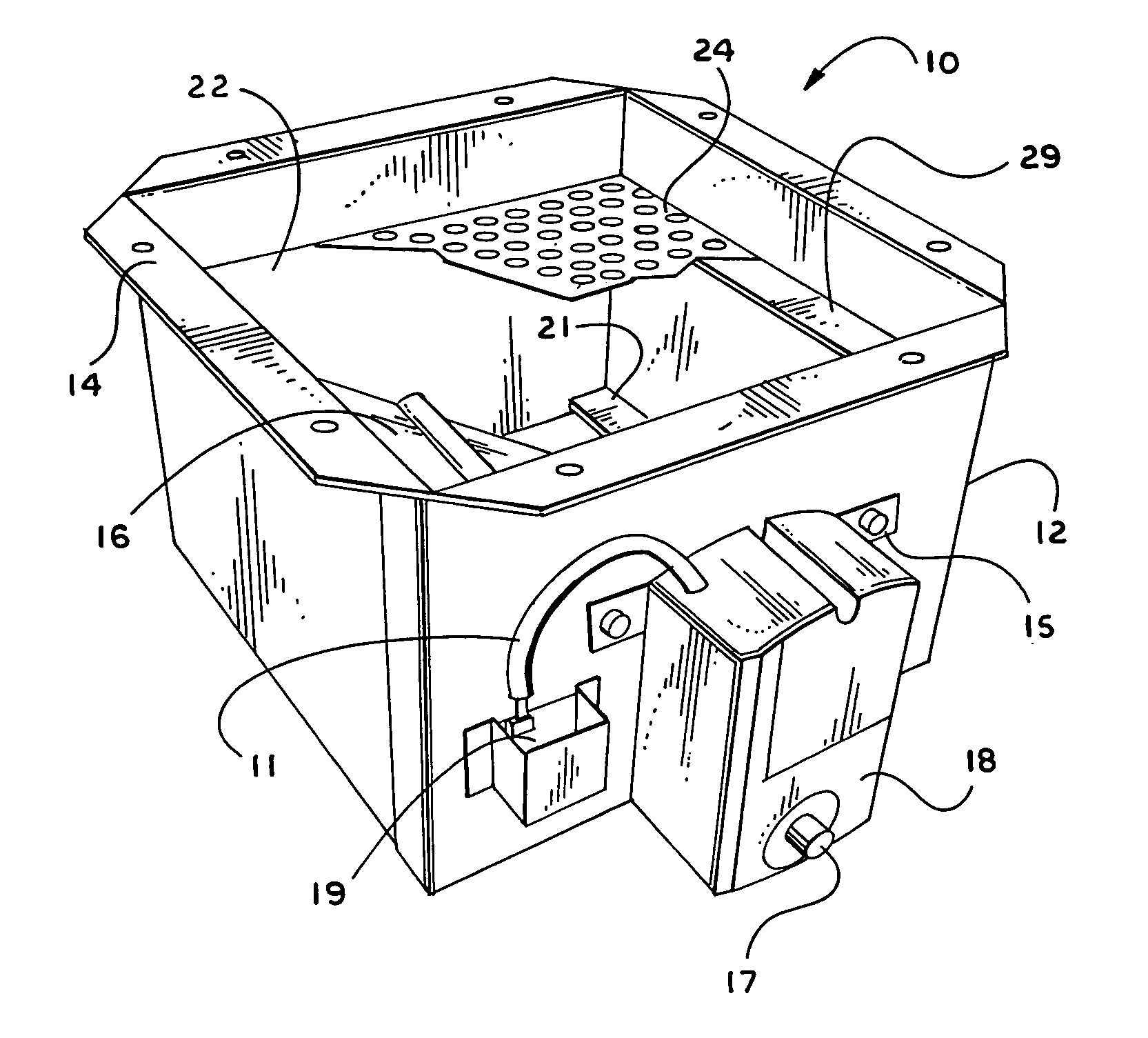

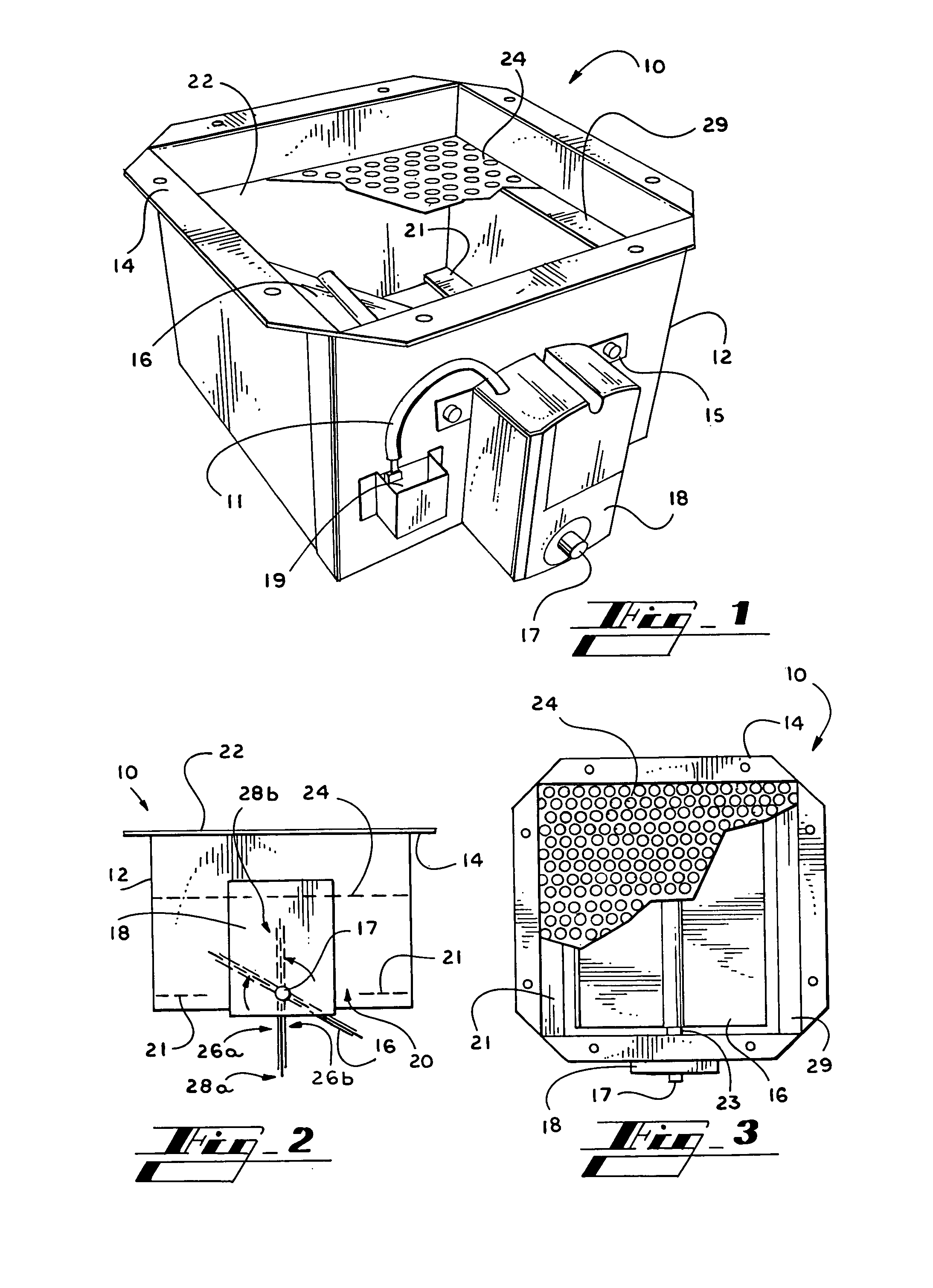

[0019] With reference to FIGS. 1-3, a round floor boot terminal 10 in accordance with the present invention is illustrated. The round floor boot terminal 10 consists of a square housing 12, an air inlet 20, an air outlet 22, a damper 16, and a floating point damper actuator 18. The square housing 12 consists of four sheet-metal sides. Extending mounting flanges 14 are located at the top of the housing 12 adjacent the air outlet 22. The air inlet 20 is downwardly facing at the bottom of the housing 12. A set of baffles 21 surround the air inlet 20 to restrict the size of the air inlet 20 to accommodate the size of the damper 16 (FIG. 2).

[0020] The rotating damper 16 is connected to a shaft 17 extending horizontally between two opposite sides of the housing 12. The floating point actuator 18 is mounted onto the housing 12 with a mounting plate 15 and connected to the shaft 17. The floating point actuator 18 rotates the shaft 17 through about a 90 degree range of motion to open and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com