Shear wall aspect ratio reducing frame (ARRF)

a technology of reducing frame and shear wall, which is applied in the direction of building reinforcements, construction, building components, etc., can solve the problems of high labor intensity, large site preparation, and large height, and achieve the effect of reducing the force on the shear wall, increasing the shear capacity, and reducing the resistance of shear forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

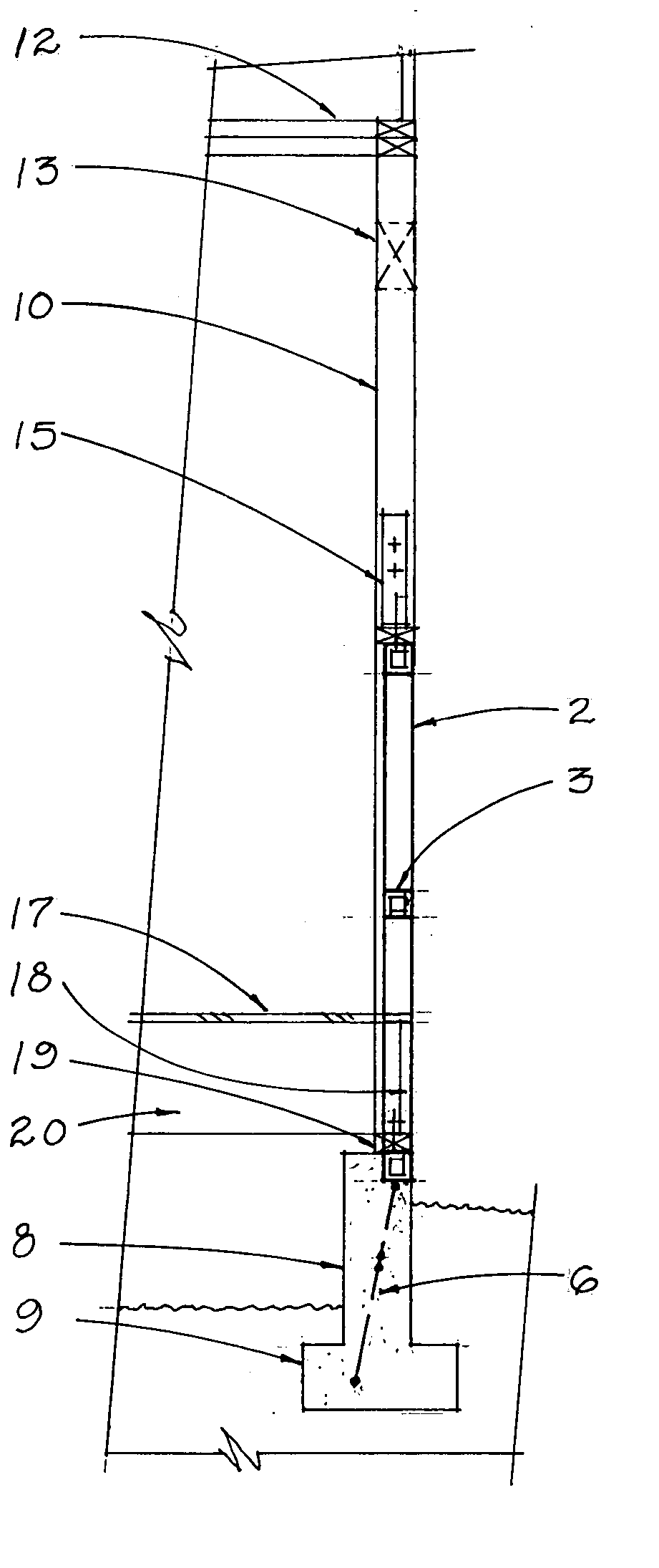

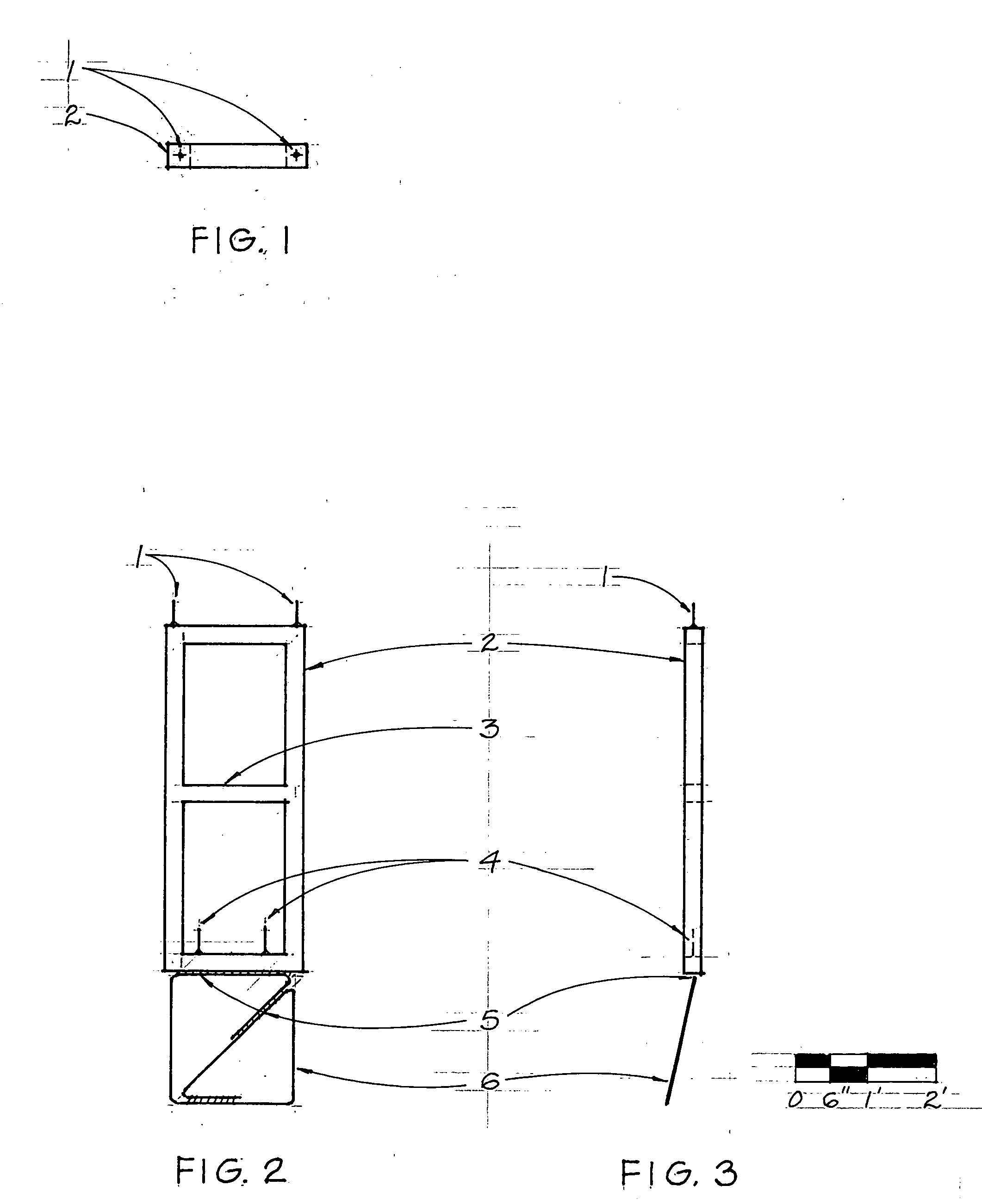

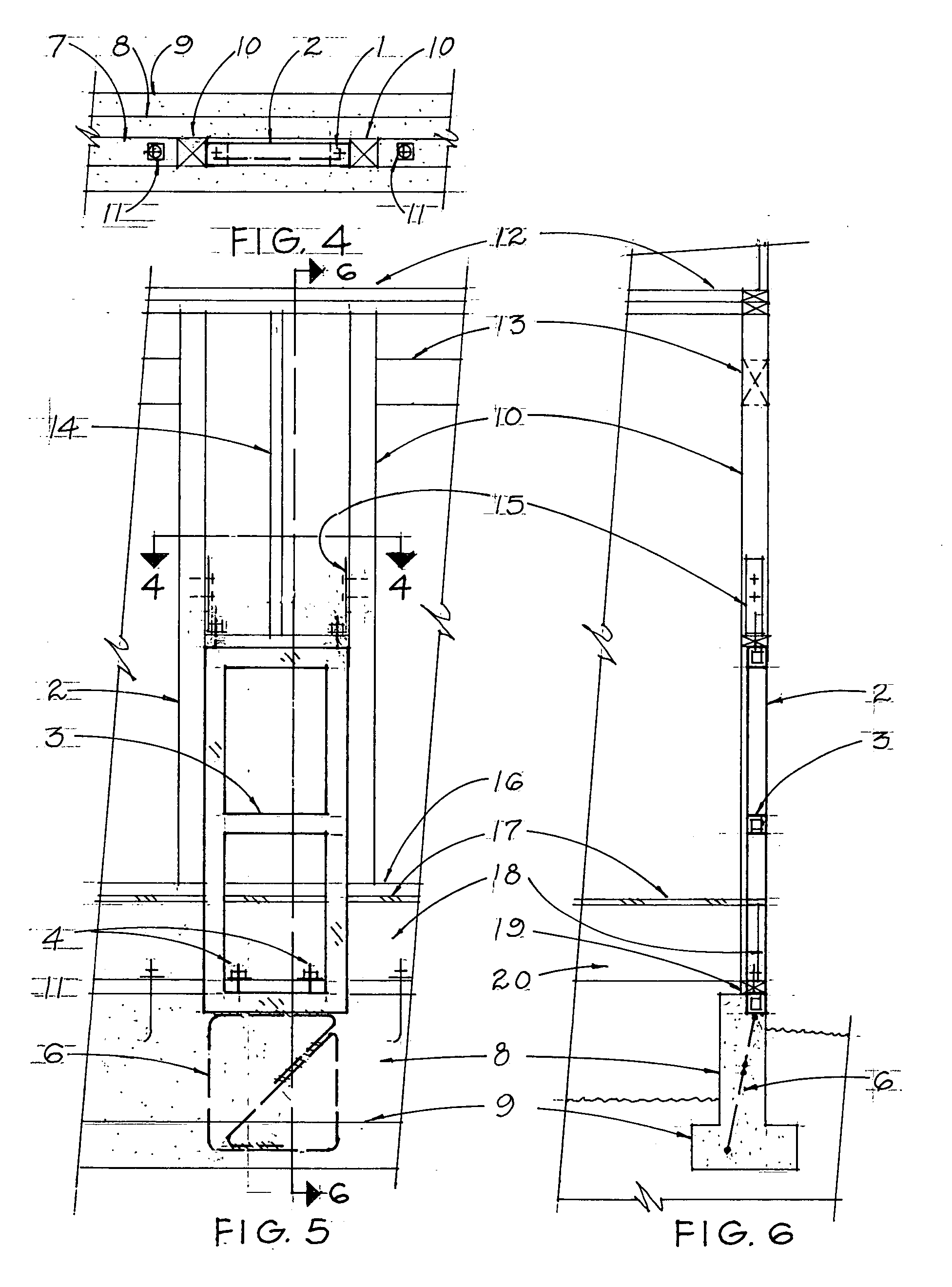

[0017] The ARRF is a shop-fabricated steel device that is installed in the foundation of a house prior to the pouring of the concrete for the foundation. During shop fabrication the five straight tube steel pieces are set in a jig and welded together. The threaded steel rods are welded into place. The rebar lower section is bent into its specified configuration, internally welded where required and then welded to the bottom of the now assembled (welded) tube steel section. The entire assembly is cleaned with acetone or equal, the rebar lower section is masked and the tube steel upper section is primed and painted. The ARRF is now ready to be transported to the construction site

DETAILED DESCRIPTION OF THE INVENTION (continued)

[0018] After the house foundation formwork has been installed, the rebar section of the ARRF is placed on dobies (small concrete spacers) and wire-tied to the adjacent formwork ensuring that it is straight, level and plumb. The foundation rebar is installed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com