Method for operating a belt retractor and a belt retractor for a safety belt

a technology of belt retractor and safety belt, which is applied in the direction of belt retractor, vehicle safety belt, belt retraction, etc., can solve the problem that the force-limiter system of the safety belt is not substantially increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

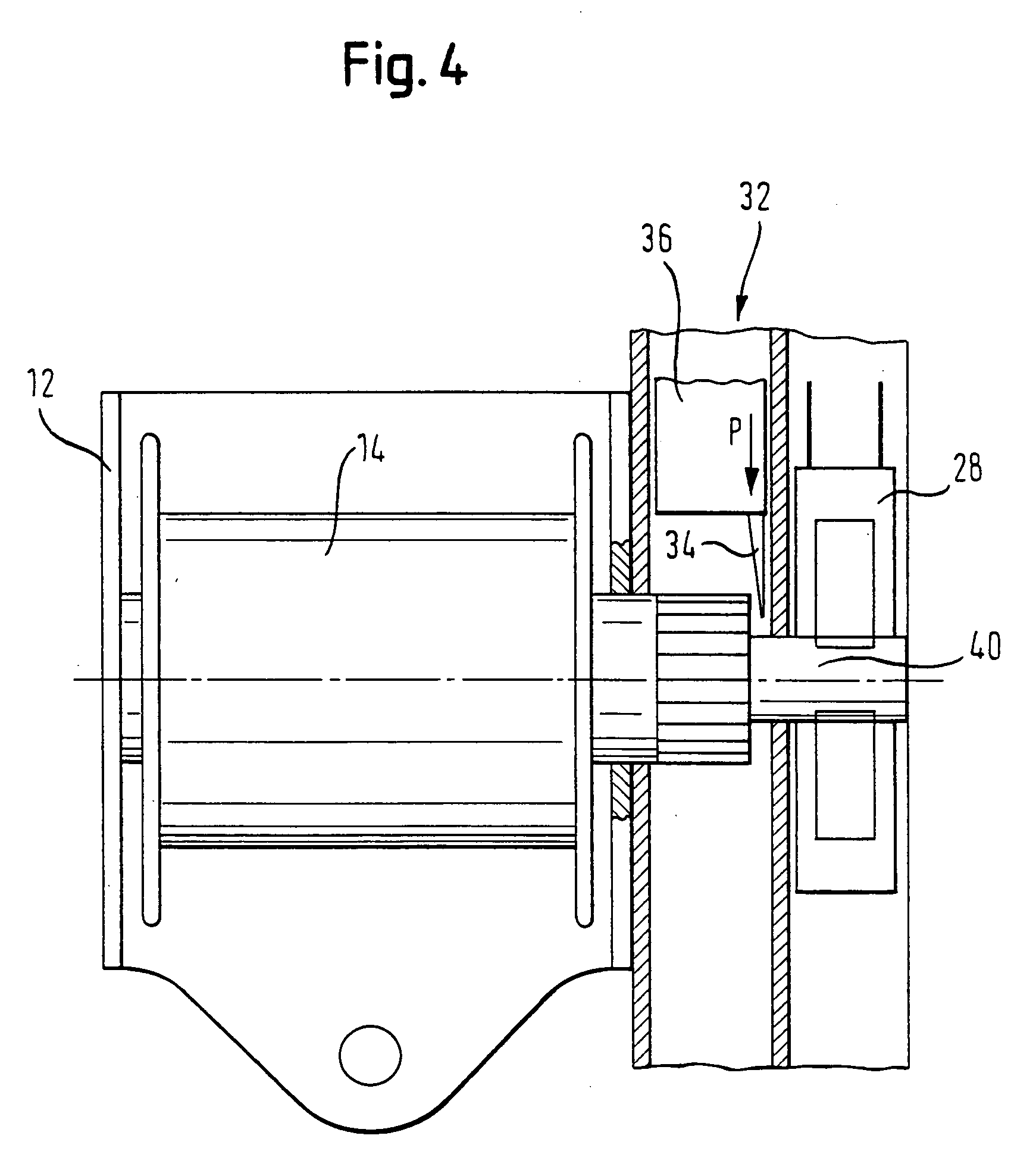

[0032] In FIG. 4 a second embodiment is shown. The safety mechanism 32 also has an actor 36 here, which can move a separating element 34. In the same manner as in the embodiment according to FIGS. 2 and 3, the separating element is constructed as a sharp blade. This blade acts here on a shaft 40 which connects the pre-tensioner drive 28 with the belt spool 14. Through activation of the pyrotechnic gas generator 26, the actor 36 moves the separating element 34 in the direction of the arrow P, whereby the shaft 40 is separated, sheared off or otherwise broken. Provision can be made that the shaft 40 is provided with a nominal fracture site.

third embodiment

[0033] In FIG. 5 a third embodiment is shown. Instead of the shaft 40, here a connecting pin 42 leads between the pre-tensioner drive 28 (symbolized here by a pinion) and the belt tensioner drive 24 (symbolized here by a pinion coupled with the belt spool 14). The connecting pin can be transferred by the actor 36 (formed here by a pressure chamber which is closed of from one end side of the connecting pin 42 and can be acted upon by the pressure of the compressed gas generated by the gas generator 26) in the direction of the arrow from the initial position shown in FIG. 5, in which the pre-tensioner drive 28 is coupled with the belt spool 14, into a separating position in which the connecting pin 42 no longer engages into the pinion of the belt tensioner drive 24 and thereby the connection to the belt spool 14 is interrupted.

fourth embodiment

[0034] In FIGS. 6 and 7 a fourth embodiment is shown. Here, also, a connecting pin 42 is used, which can be transferred from an initial position (see FIG. 6) into a separating position (see FIG. 7). In the initial position, the connecting pin 42 connects two toothed wheels 50, 52 which are part of a gear 54 between the electric motor 30 of the pre-tensioner drive and the belt spool 14. In the initial state, the connecting pin 42 provides a torque-transferring connection between the two toothed wheels 50, 52. At the same time, it serves for mounting. A slider 56 engages on the connecting pin 42, which slider can be acted upon by the actor 36 so that it draws the connecting pin 7 in the direction of the arrow P into the separating position. In the latter, the torque-transferring connection between the two toothed wheels 50, 52 is interrupted, so that the belt spool can turn in the unwinding direction without the electric motor 30 having to be entrained.

[0035] According to a further de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com