Printing unit

a printing unit and printing technology, applied in the field of printing units, can solve the problems of large space occupation, large maintenance work, and large size of printing units incorporated in such information terminals, and achieve the effect of simple in itself, complicated maintenance work, and simple replacement of rolled sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

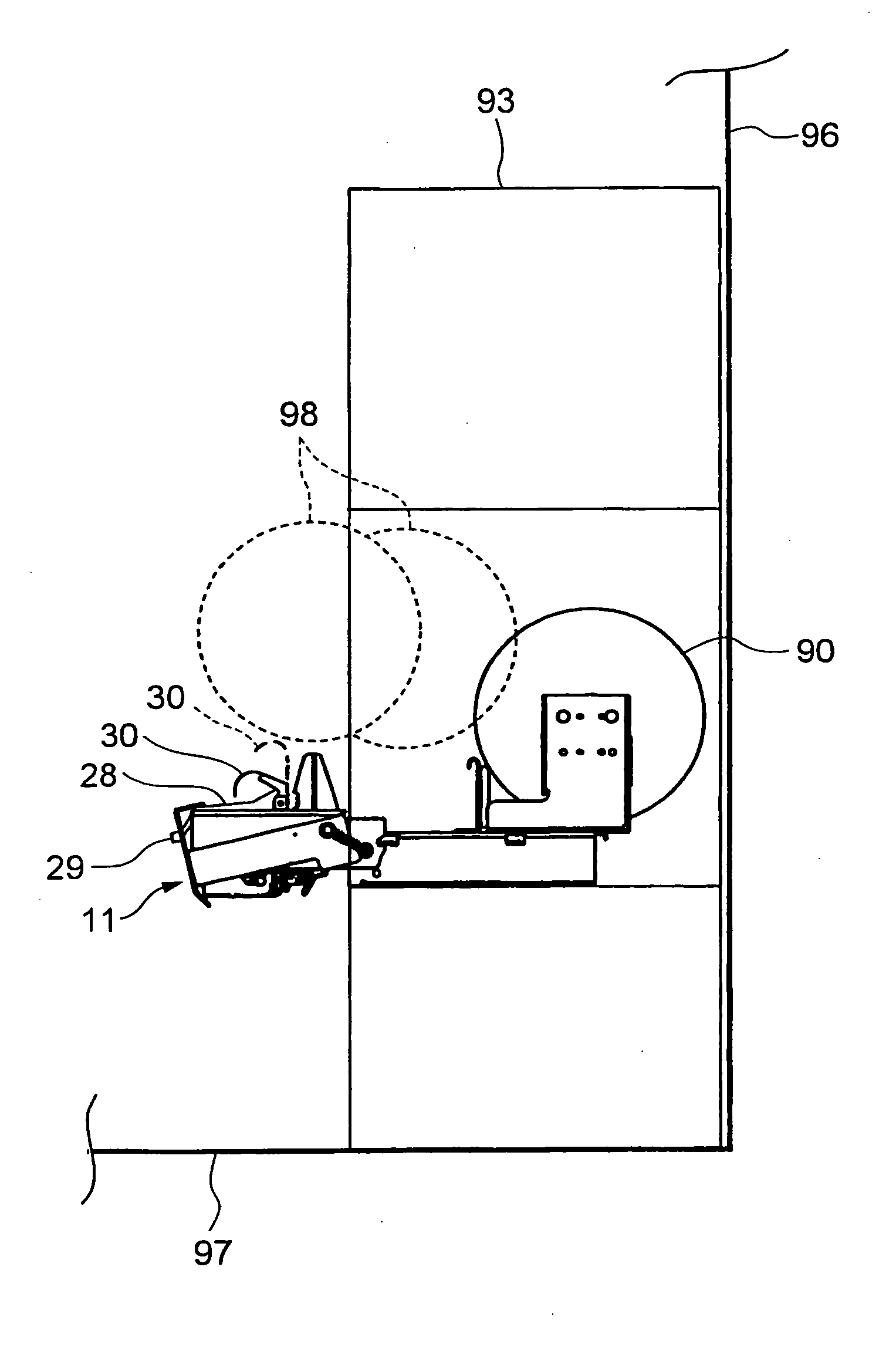

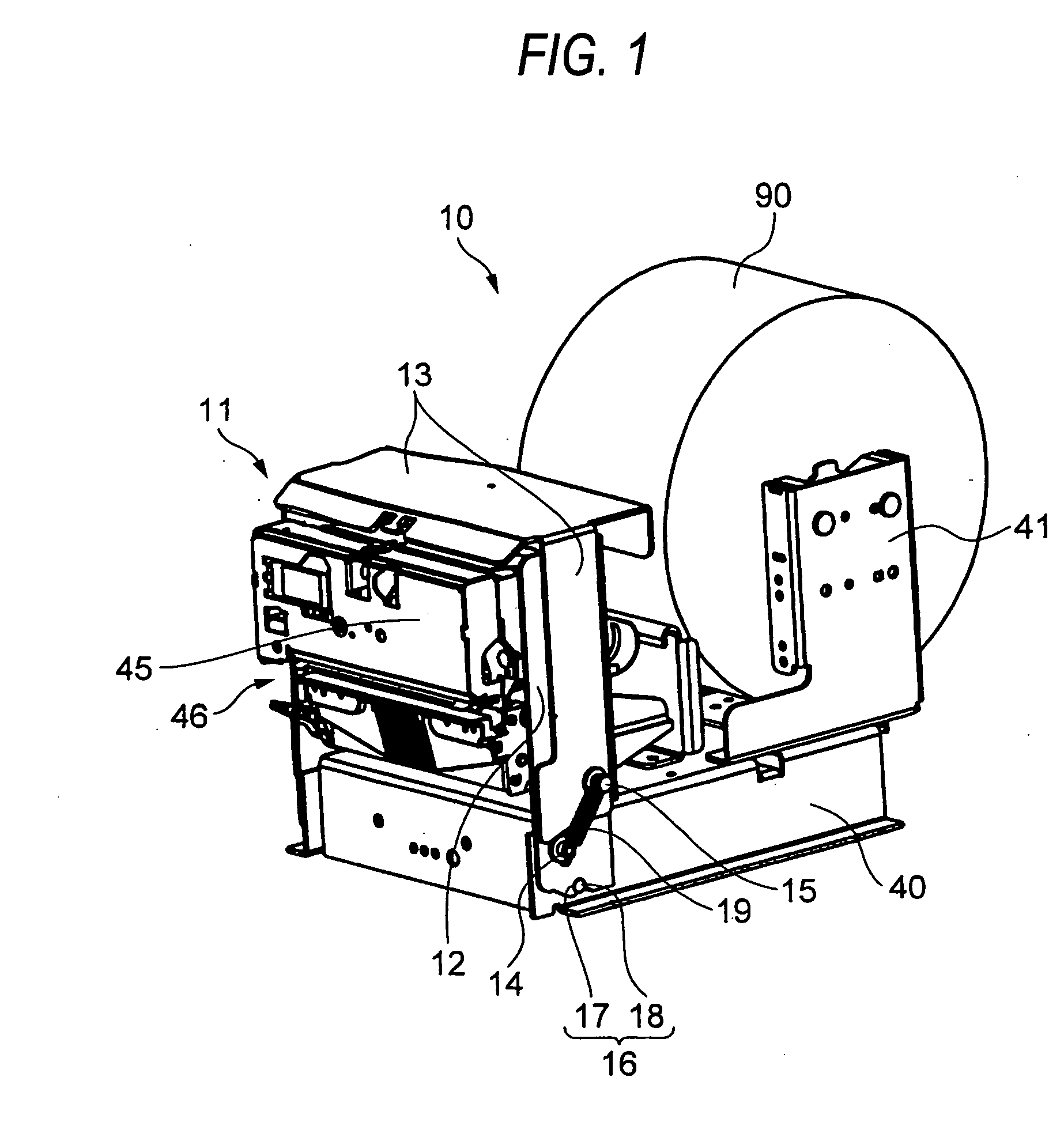

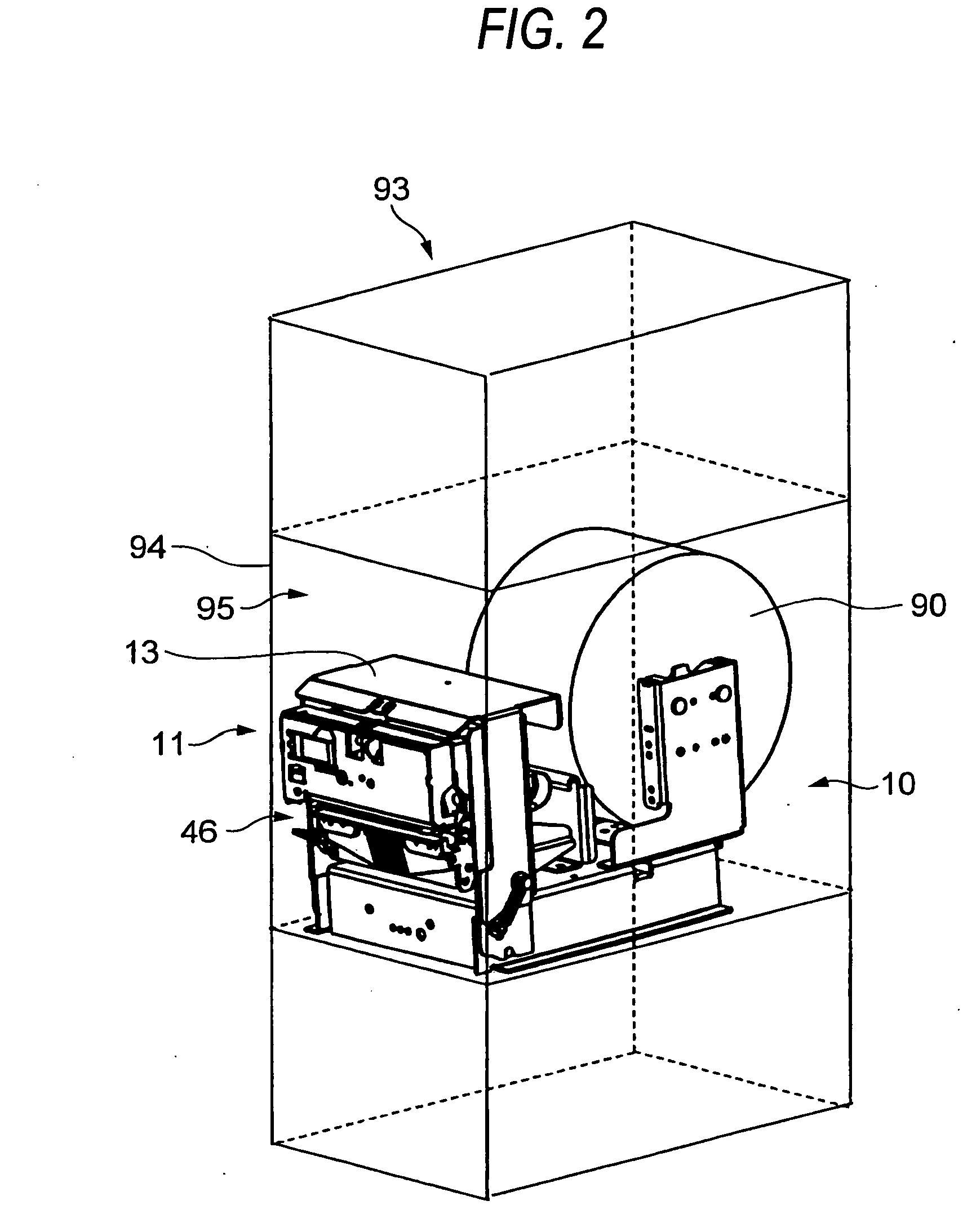

[0076]FIG. 1 shows a printing unit 10 according to the invention. In this embodiment, the printing unit 10 is equipped with a front section 11 that is pivotable outward, a base frame 40, and a rolled sheet holder 41 for holding a rolled sheet 90 inside the printing unit 10. The front section 11 includes a release lever 13 and a movable frame 12 and is lifted up by pulling, to the front side, the release lever 13 that is provided on the front side of the apparatus. As a result, the movable frame 12 is unlocked and can be pivoted forward. Therefore, by pulling the release lever 13 to the front side together with the movable frame 12, the entire front section 11 is tilted forward. Since the movable frame 12 can be unlocked and the front section 11 can be tilted forward merely by such a simple manipulation (pulling the release lever 13 to the front side), the front portion can be easily freed with one hand. Although the front portion can be freed by pulling the release lever 13 to the f...

second embodiment

[0108]FIGS. 15 and 16 show a printing unit according to the invention. This printing unit is different from the printing unit 10 of FIGS. 1 to 14 in the release lever 32 and the buffer plate 30 escape mechanism. In this embodiment, the release lever 32 is provided with projections 35, and an actuator shaft 36 extending parallel with the buffer plate 30 is attached to the tip portions of the projections 35. The buffer plate 30 is provided with, on both sides, a link portion 37 having a hole. The actuator shaft 36 is attached to the release lever 32 in a state that it penetrates through the holes of the link portions 37. Therefore, the release lever 32 is connected to the buffer plate 30 via the link portion 37, and the projections 35, the actuator shaft 36, and the link portions 37 constitute a link mechanism. When the release lever 32 is pivoted counterclockwise, the actuator shaft 36 rotates counterclockwise about the second shafts 15 which are the pivot centers of the release leve...

third embodiment

[0110] FIGS. 17 to 19 show a printing unit according to the invention. This printing unit is different from the printing units of FIGS. 1 to 16 in the buffer plate 30 escape mechanism.

[0111] In this embodiment, the release lever 80 is inclined inward by a prescribed angle in the locked state. The release lever 80 is provided with an actuator plate 81 that is bent at a prescribed angle and serves to actuate the buffer plate 30. The buffer plate 30 is pivotally supported by the movable frame 12 via the pivot shaft 31, and is provided with, in its rear, an engagement portion 38 that is bent upward and engages with the actuator plate 81.

[0112] With the above structure, when the release lever 80 is pivoted, the actuator plate 81 pushes the engagement portion 38 counterclockwise and thereby causes the buffer plate 30 to escape to the position shown in FIG. 19. In this embodiment, it is possible to cause the buffer plate 30 to escape without using a wire by a simpler mechanism than in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com