Method and apparatus for producing labeled, plastic foam containers, and product of same

a technology of labeling and packaging, applied in the direction of manufacturing tools, liquid handling, closures using stoppers, etc., can solve the problems of poor printing capability difficult to apply print or graphical designs directly to the surface of plastic foam containers, eps containers suffer from certain limitations, etc., to improve printability, improve rigidity, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following describes machines for labeling plastic foam containers, and a process for using such machines, in accordance with various embodiments of the present invention. It should be appreciated, however, that the following description is intended to be merely exemplary of the various features of the invention and should not limit the proper scope of the appended claims.

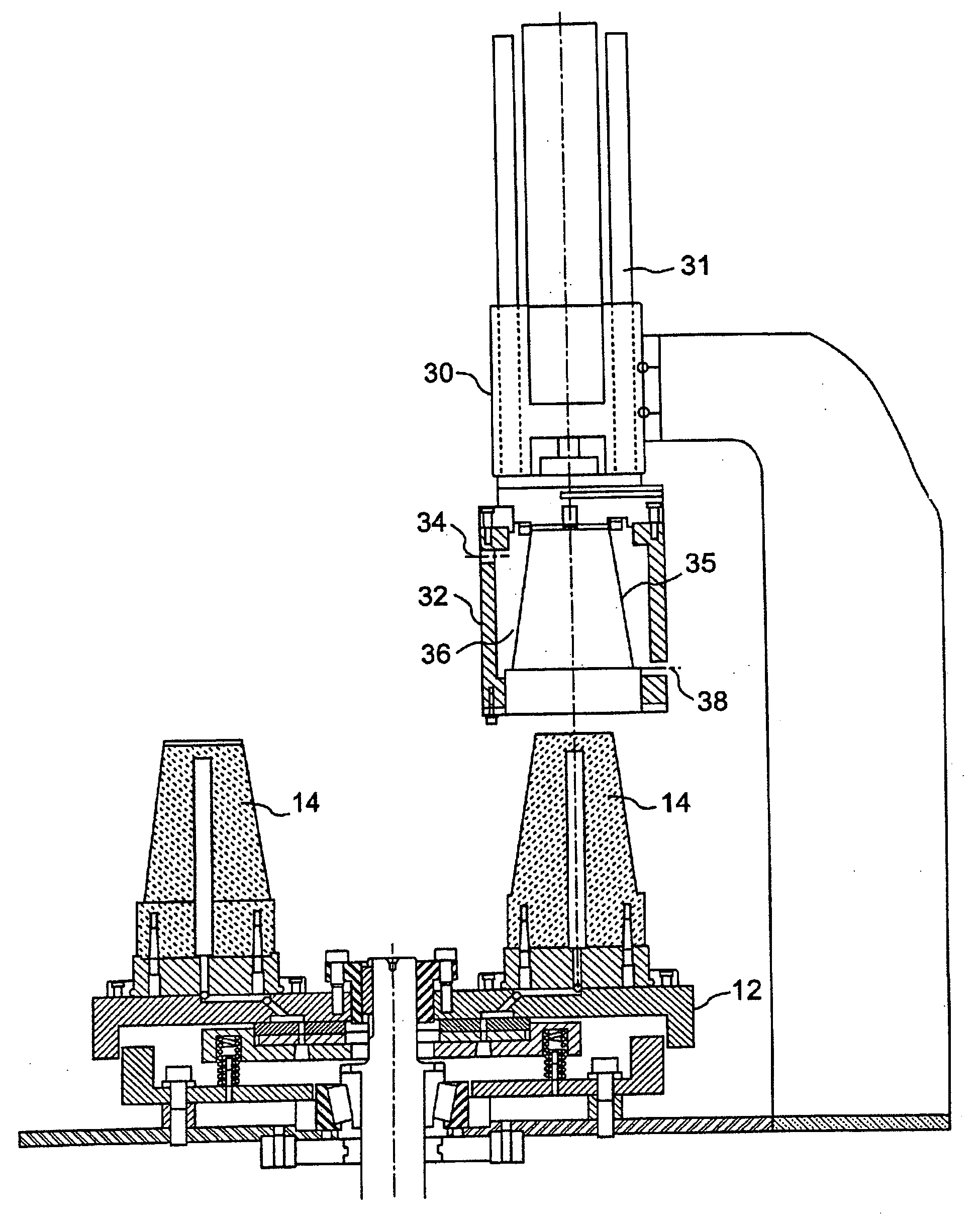

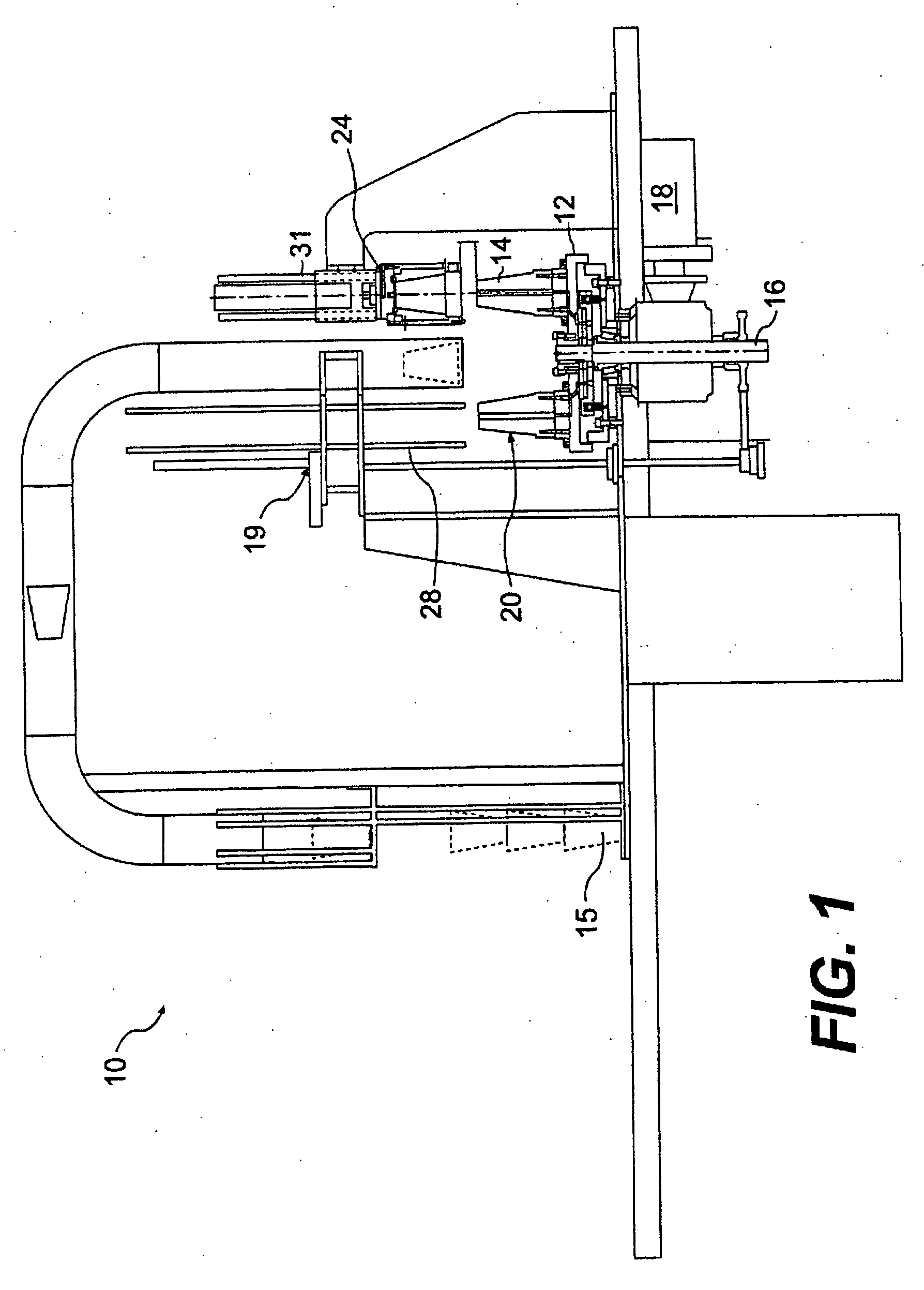

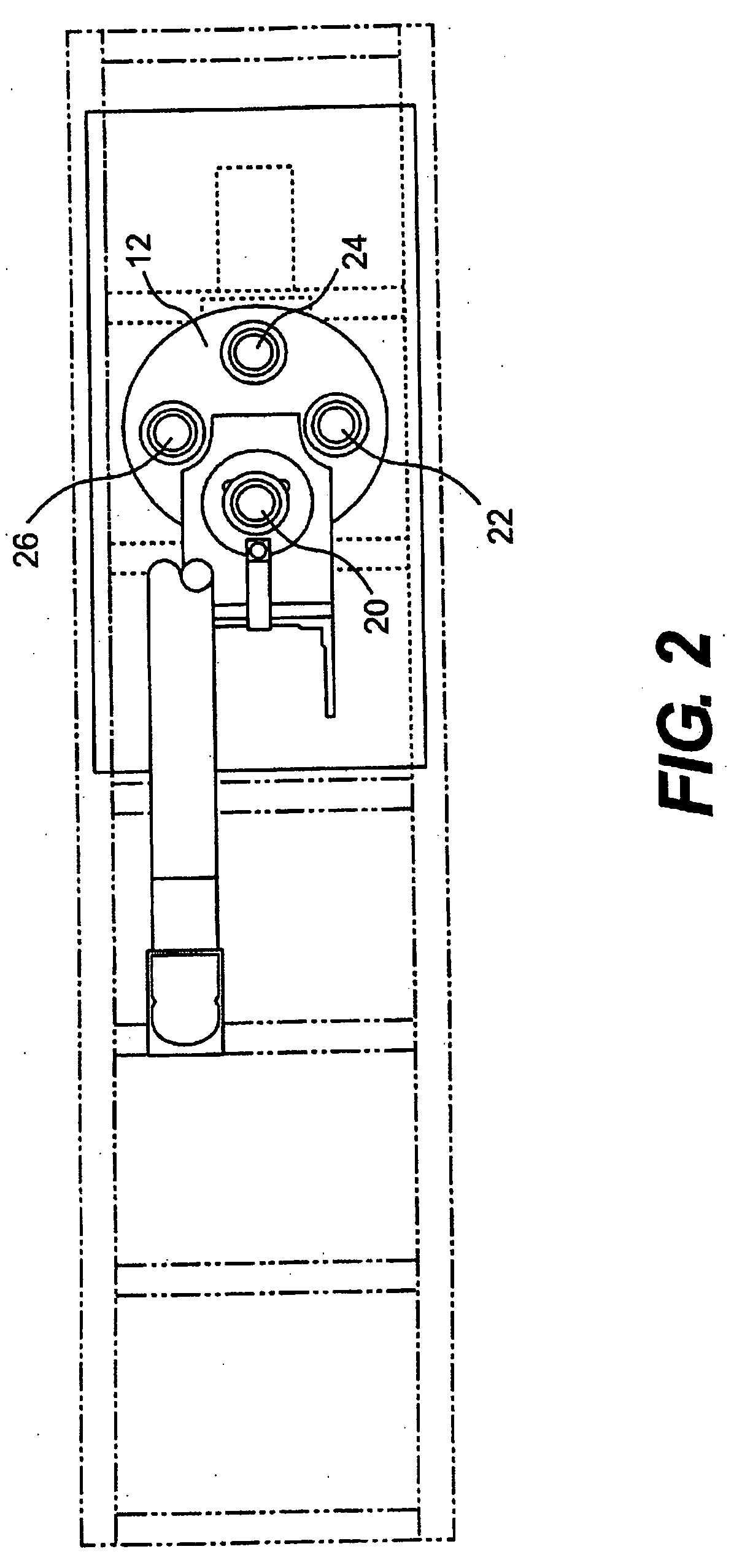

[0033]FIG. 1 is a schematic view of a machine 10 for forming a labeled plastic foam container 15 in accordance with a first embodiment of the invention. As illustrated, the machine 10 includes a turret 12 having a plurality of mandrels 14 attached thereto. Each mandrel 14 has a tapered shape and is configured to receive a plastic foam container 17, which is preferably an EPS cup.

[0034] The turret 12 of this example is driven by a shaft 16, which is operatively connected to an index drive 18, of a type conventionally known in the art. The index drive 18 rotates the turret 12 by 90 degrees so as to precis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com