Interlocking honeycomb-cored panel system for construction of load supporting surfaces

a technology of honeycomb cores and load supporting surfaces, which is applied in the direction of bridges, building components, constructions, etc., can solve the problems of affecting requiring immense labor to complete the road, and essentially impossible to remove, so as to improve the visual effect of the ground suppor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The panels of the present invention may offer a durable, reusable system for construction of roadways and other ground support surfaces. The panels can be assembled to create work surfaces of various dimensions. Because the panels are designed to interlock with one another they can be connected together in a wide number of combinations to provide the correct alignment for any ground support application. This flexibility of assembly, along with the durability of the panels allows for quick and easy installation, usually requiring only one layer of panels on virtually any ground substrate. The panels may be formed to be positively buoyant to float on water, to enhance their usefulness.

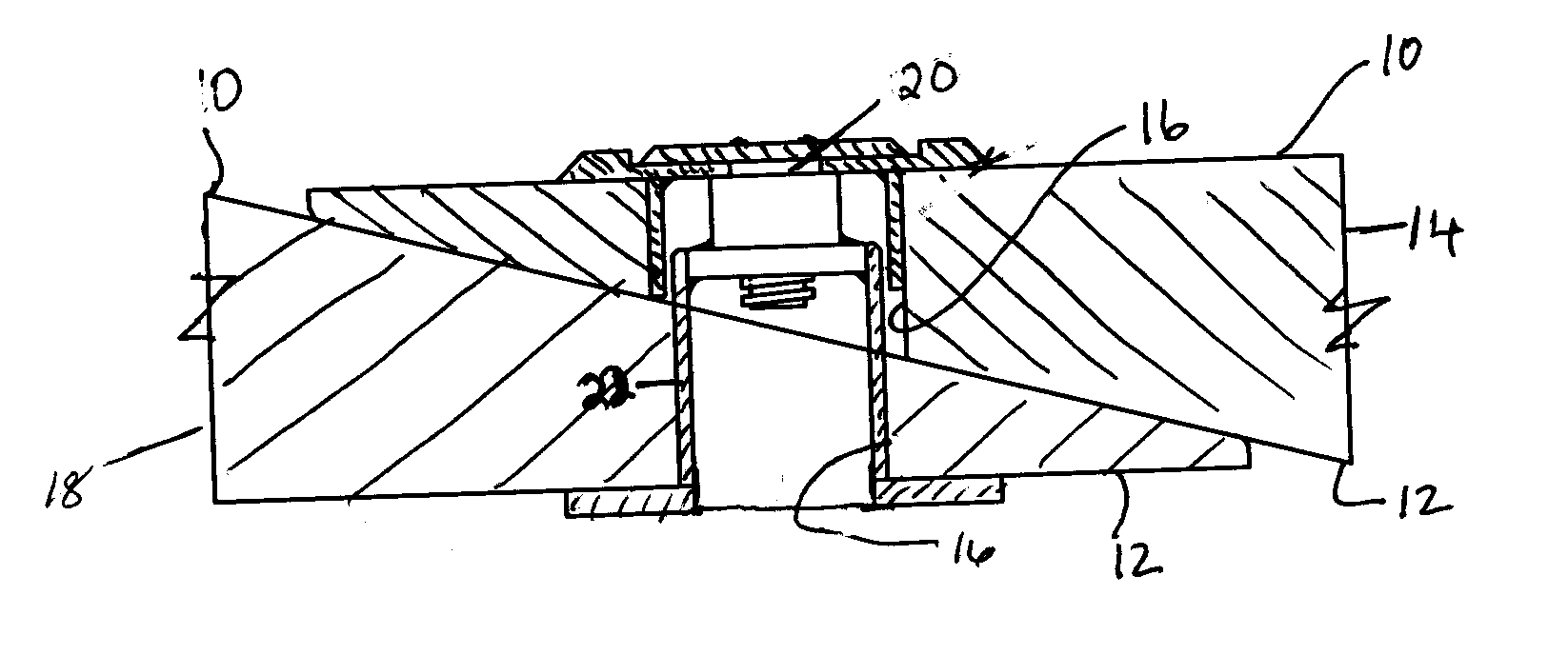

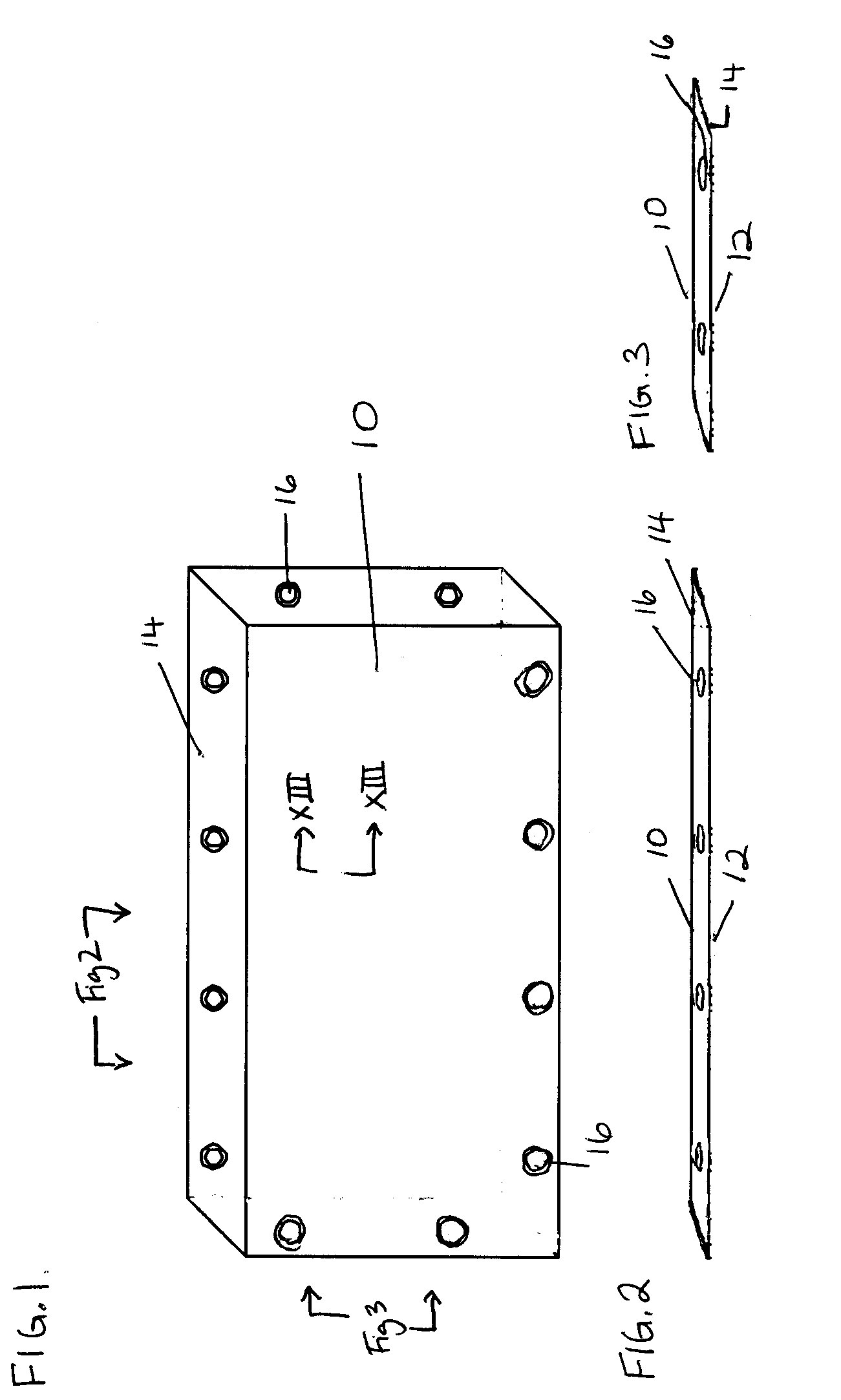

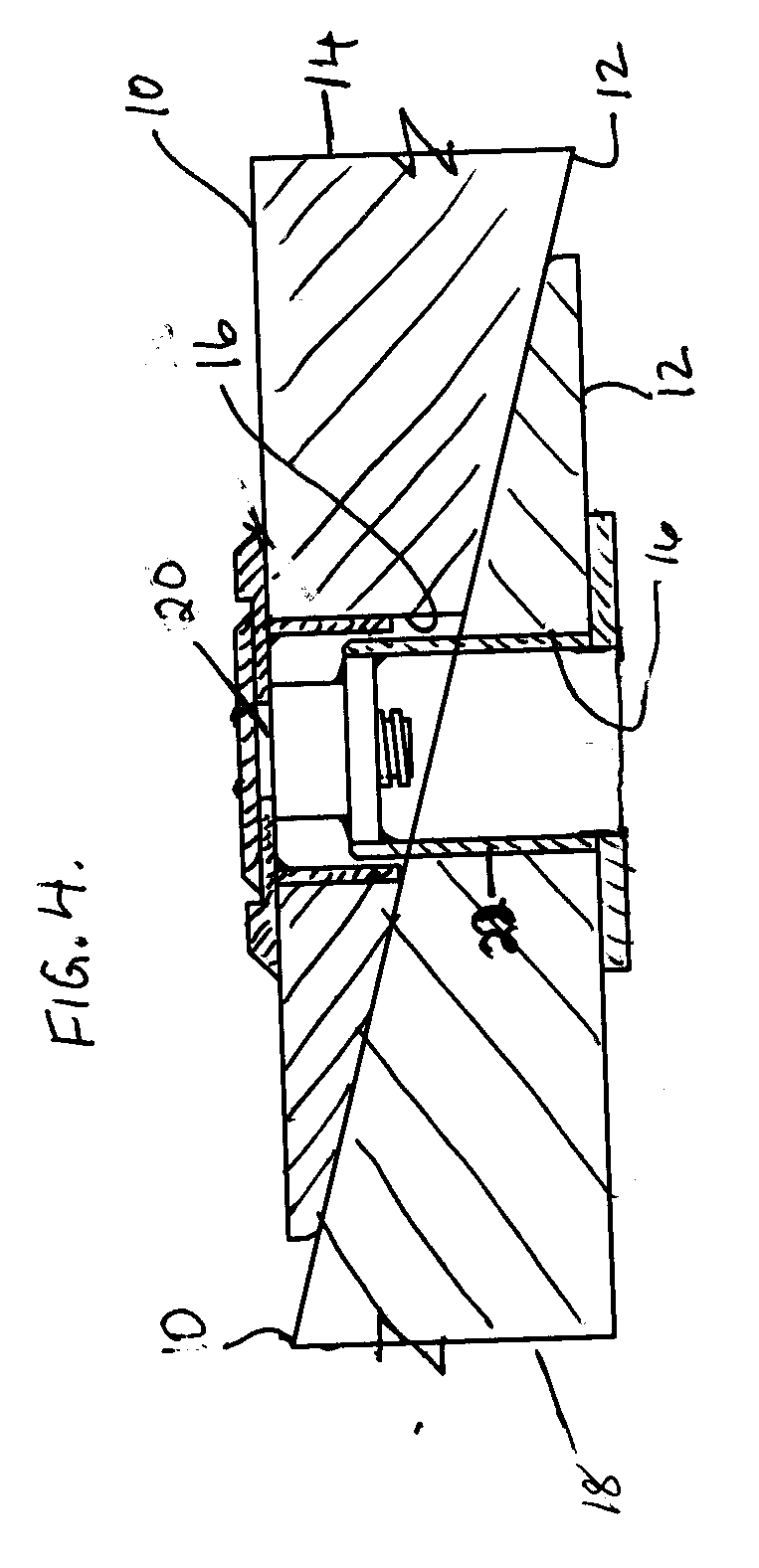

[0031] Referring to FIGS. 1 to 3, a panel useful in the system is provided with an expansive upper surface 10 and a lower surface 12. A panel may include a wedge-shaped edge 14 along one or more selected edges. In the embodiment shown, all the sides of the panels have a wedged-shaped edge. A wedg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com