High velocity ammunition system and firearm

a high-speed, ammunition technology, applied in the direction of ammunition projectiles, weapons, ammunition loading, etc., can solve the problem of fragmentation of sabots, and achieve the effect of high muzzle velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

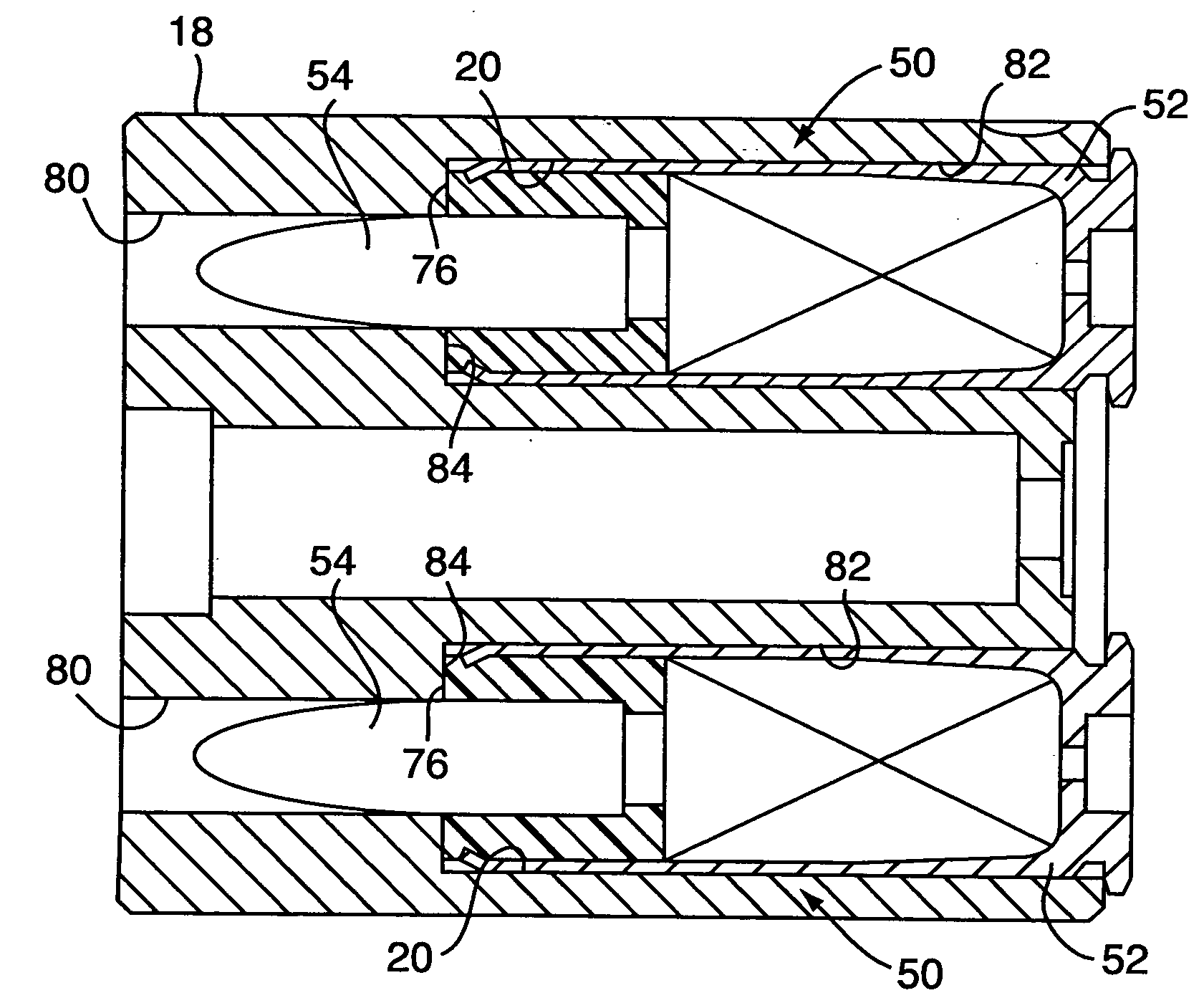

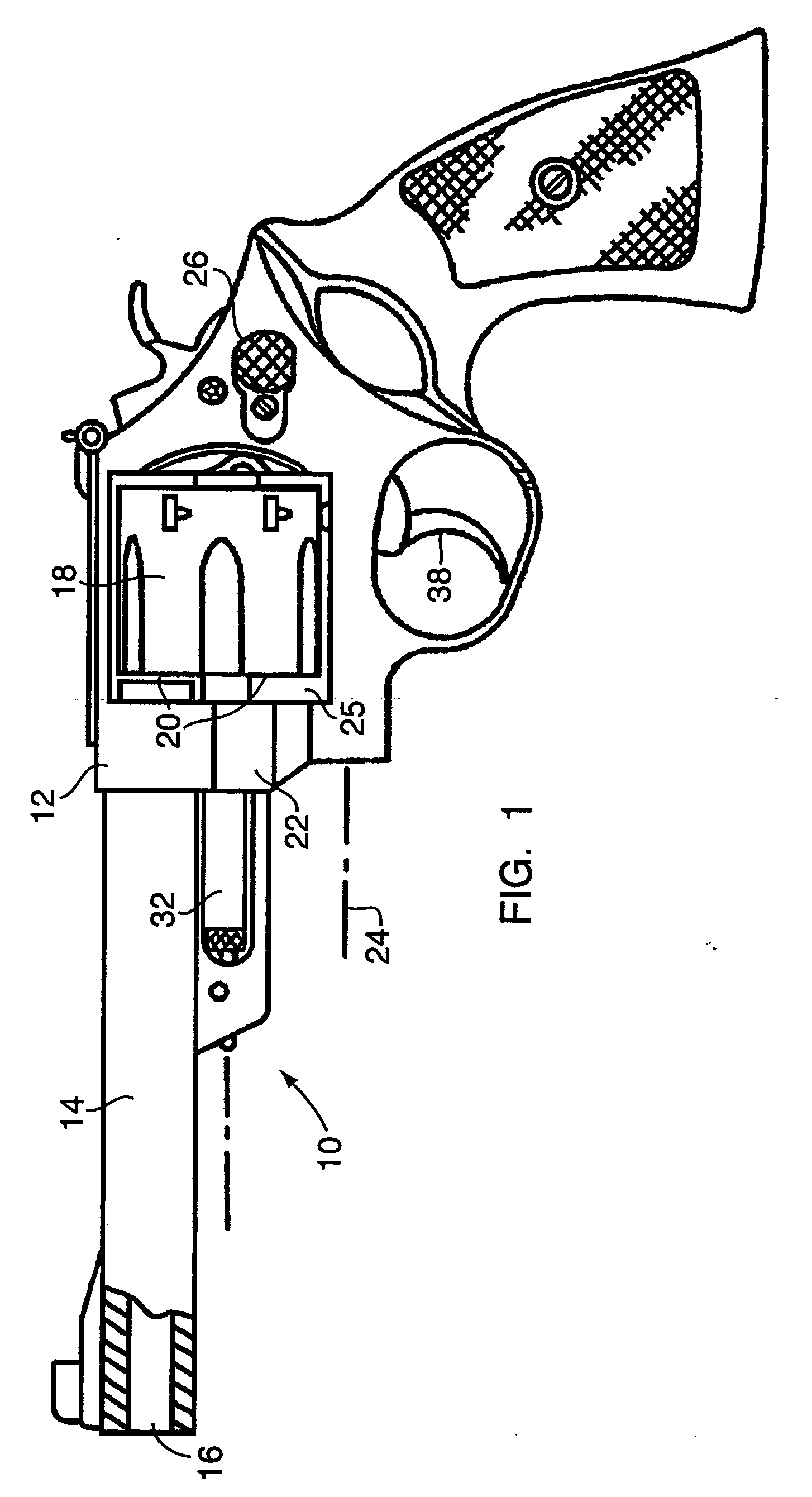

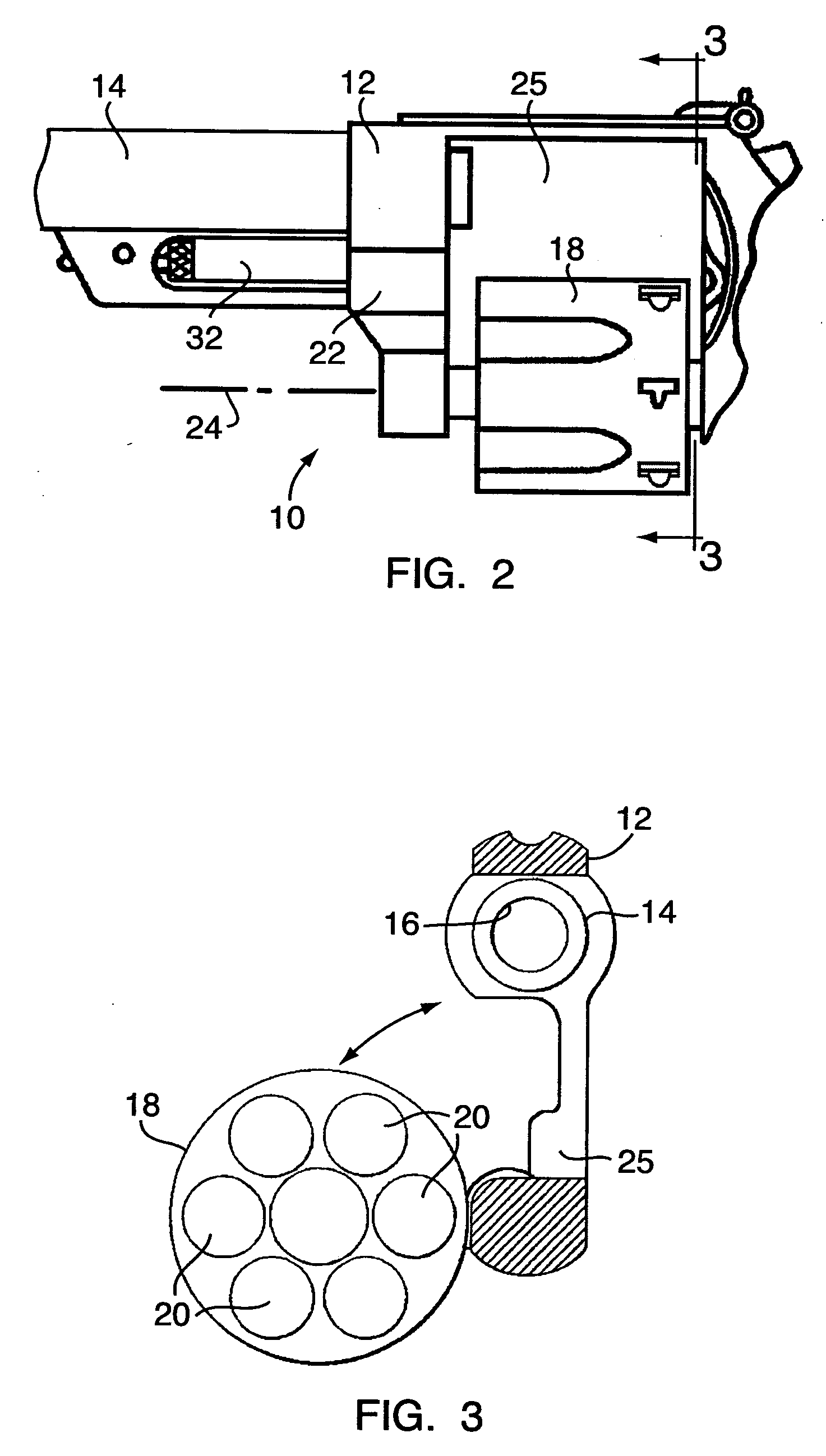

[0028] Turning now to the drawings, a high velocity firearm or revolver embodying the present invention and particularly adapted to fire high velocity ammunition embodying the invention is shown in FIG. 1 and indicated generally by the reference numeral 10. The illustrated firearm 10 is a modified Model 500 Smith & Wesson Revolver, manufactured by Smith & Wesson Corp., Springfield Mass., assignee of the present invention, and includes a frame 12 and an axially elongated barrel 14 mounted in fixed position and projecting in and axially forward direction from the frame. The barrel defines a rifled bore, 16 which extends axially through it from a breech or rear end to a forward or muzzle end. The revolver 10 further include a rotary cylinder 18, which is supported for indexable rotation relative to the frame has a circumaxially series of equangularly spaced apart chargeholes 20,20 extending therethrough. The chargeholes are chambered in accordance with the present invention to receive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com