Collapsible bulk material container

a container and bulk material technology, applied in the field of shipping and storage containers, can solve the problems of bursting containers, unique packaging problems, load shifting, etc., and achieve the effect of convenient erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

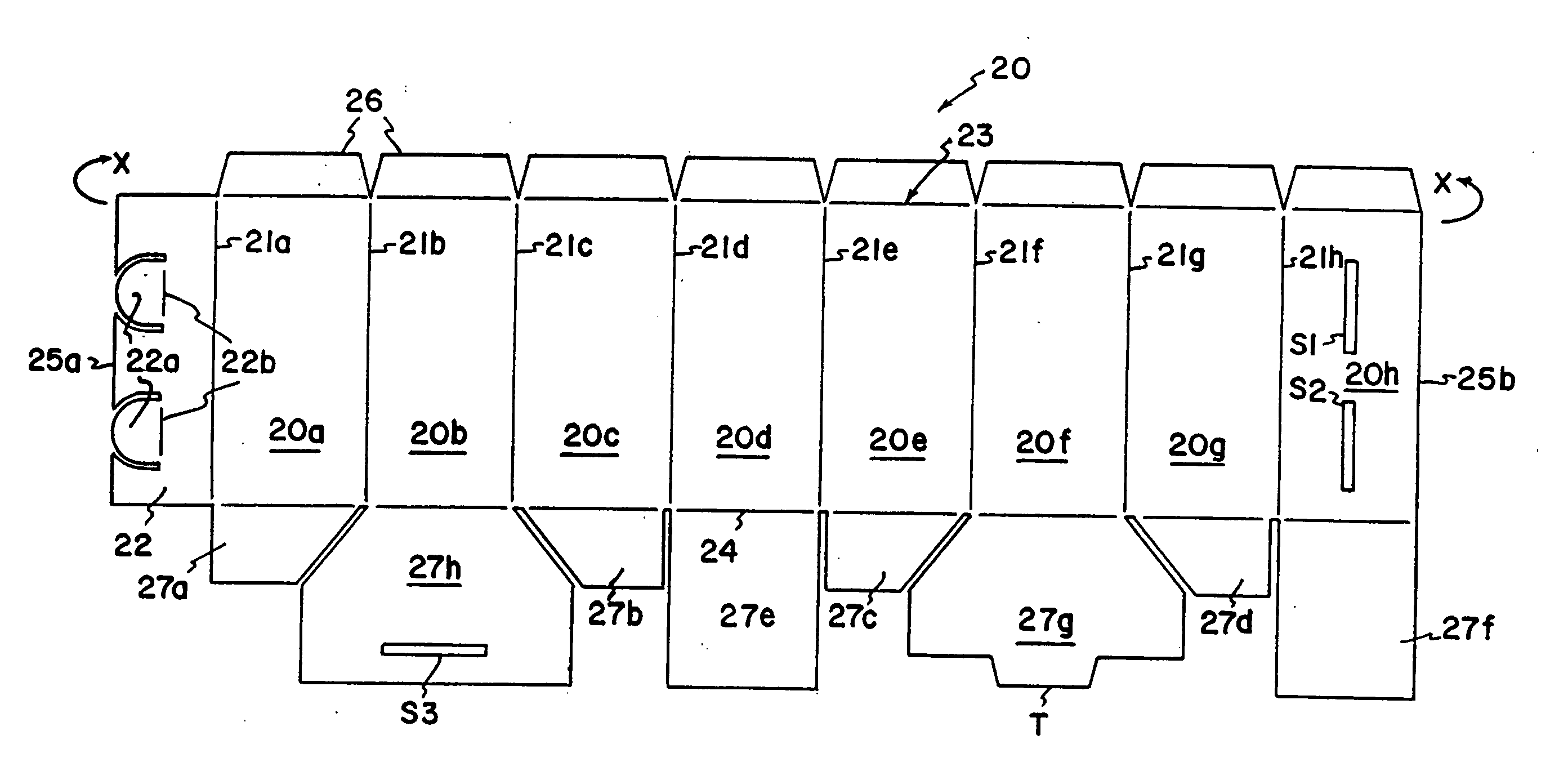

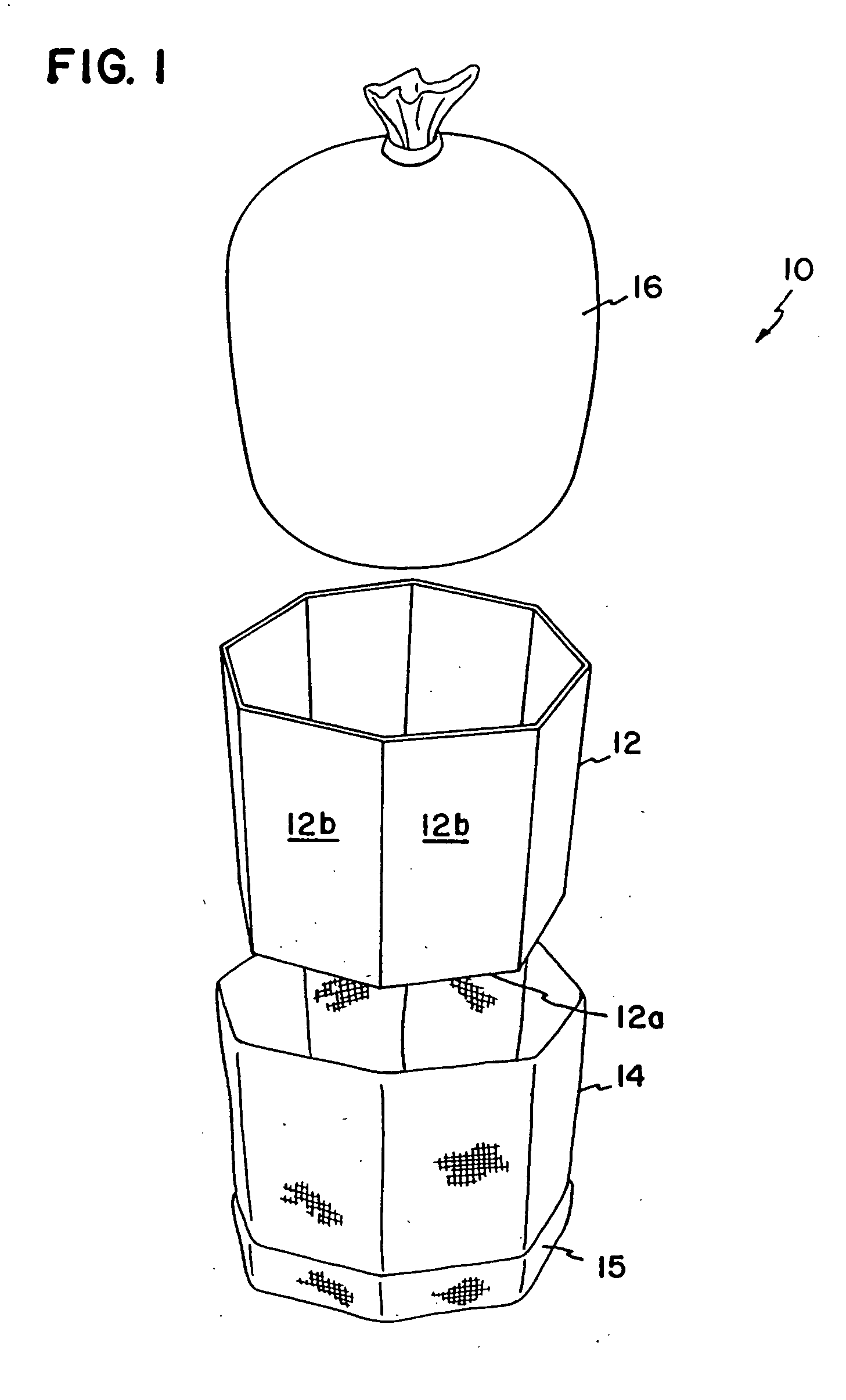

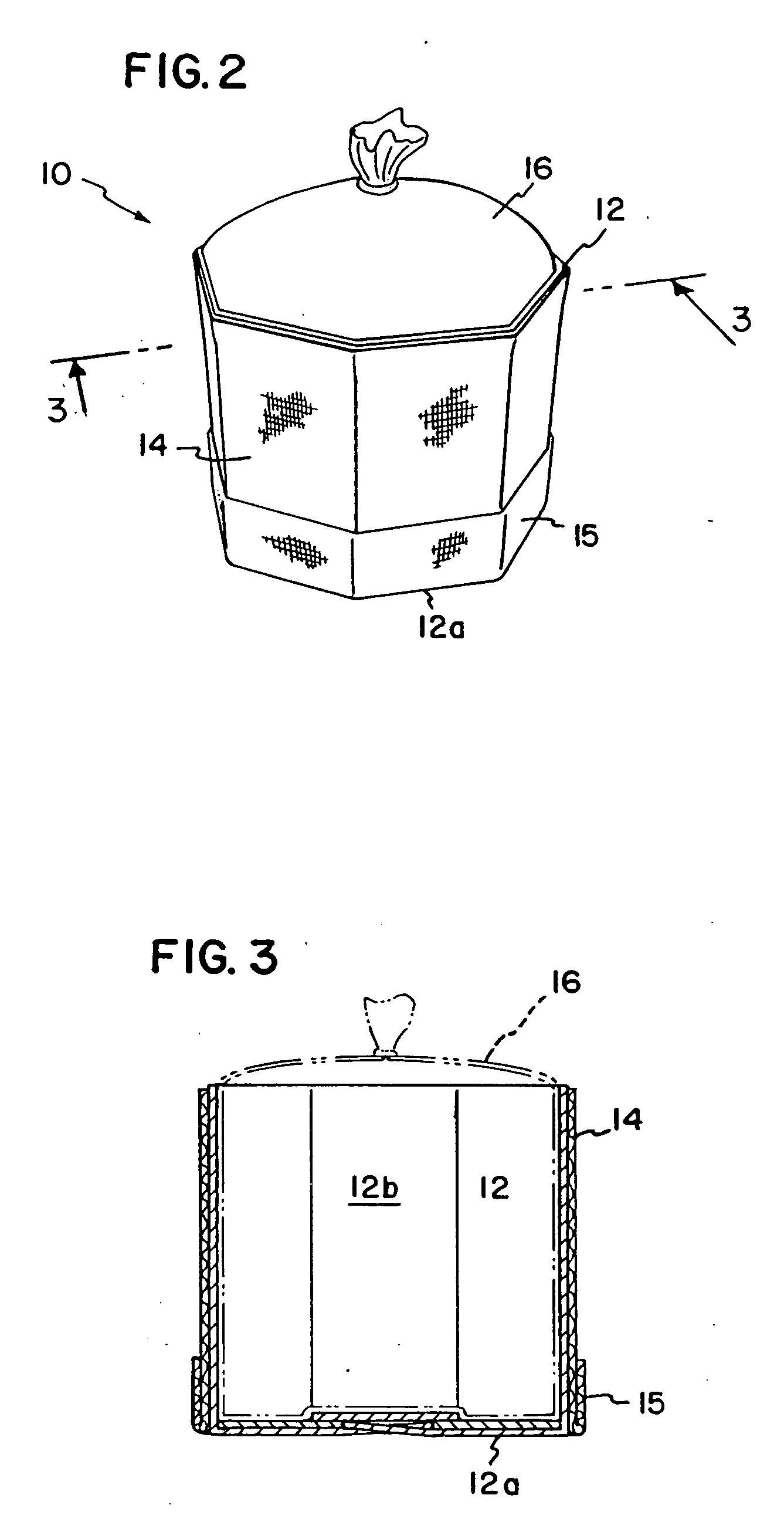

[0048] the forming member, constructed from corrugated cellulose (cardboard) material, is illustrated at 20 in FIGS. 4A-4D. In the preferred embodiment, the forming member 20 is configured from a single piece of corrugated material that is scored and patterned for folding, as illustrated in FIG. 4A. Referring thereto, the forming member 20 has eight sidewall portions 20a-20h consecutively connected and defined by intervening fold lines 21a-21h respectively, which eventually define the eight “corners” of the forming member. A connecting wall member 22 is contiguous with sidewall 20a and extends outwardly from fold line 21a. Connector wall 22 has a pair of arcuate tabs 22a cut into the wall and projecting back from the side edge 25a back to fold lines 22b. The forming member 20 also has an upper edge 23, a lower edge fold line 24 and oppositely disposed side edges 25a and 25b. Each of the sidewalls 20a-20h has a tab 26 projecting upwardly therefrom that folds along the upper edge 23 o...

second embodiment

[0055] A second octagonal embodiment of a forming member 20′ is illustrated in FIGS. 5A-5D. The general function and folding pattern of the corrugated sheet defining the forming member 20′ is basically the same as that of the forming member 20 with the following changes: (1) the uniform width dimension of the sidewalls has been changed to an irregular width pattern; (2) the upper individual tabs 26 of the forming member 20 have been replaced by a pair of elongate tabs 26′ having fold score marks 26a replacing the notched cuts of the forming member 20 pattern; and (3) the slot S3 of bottom tab 27h has been deleted in bottom tab 27h′ of the second forming member, and the lower edge of bottom 27g′ has been reconfigured to include three tabs T1, T2 and T3, separated by a pair of notches. When assembled as illustrated in FIG. 5D, the second embodiment forming member 20′ provides a more elongated octagonal structure than the regular rectangular structure of the FIG. 4 forming member.

[0056...

third embodiment

[0072] The inserts 64 and 64′ described above did not have any “bottoms”. However, the one-piece insert, constructed from corrugated cellulose (cardboard) material, which does have a bottom structure, is illustrated at 20 in FIG. 4A. In this configuration, the embodiment of the forming member, previously described and illustrated at 20 in FIGS. 4A-4D, is used as the one-piece insert, which is placed within an outer forming member 12. When so used, the insert is sized smaller than the outer forming member in order to fit within the forming member 12. This embodiment is configured and folded according to the directions given above for the embodiment of the forming member illustrated at 20 in FIGS. 4A-4D.

[0073] The one-piece insert configurations described above are by no means exhaustive of the configurations that are possible. Depending upon the forming member configuration utilized, the insert should be accordingly shaped and configured to fit within the forming member. While severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com