Wind energy installation comprising conductor rails

a conductor rail and wind energy technology, applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of costly process, and achieve the effect of convenient, economic and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

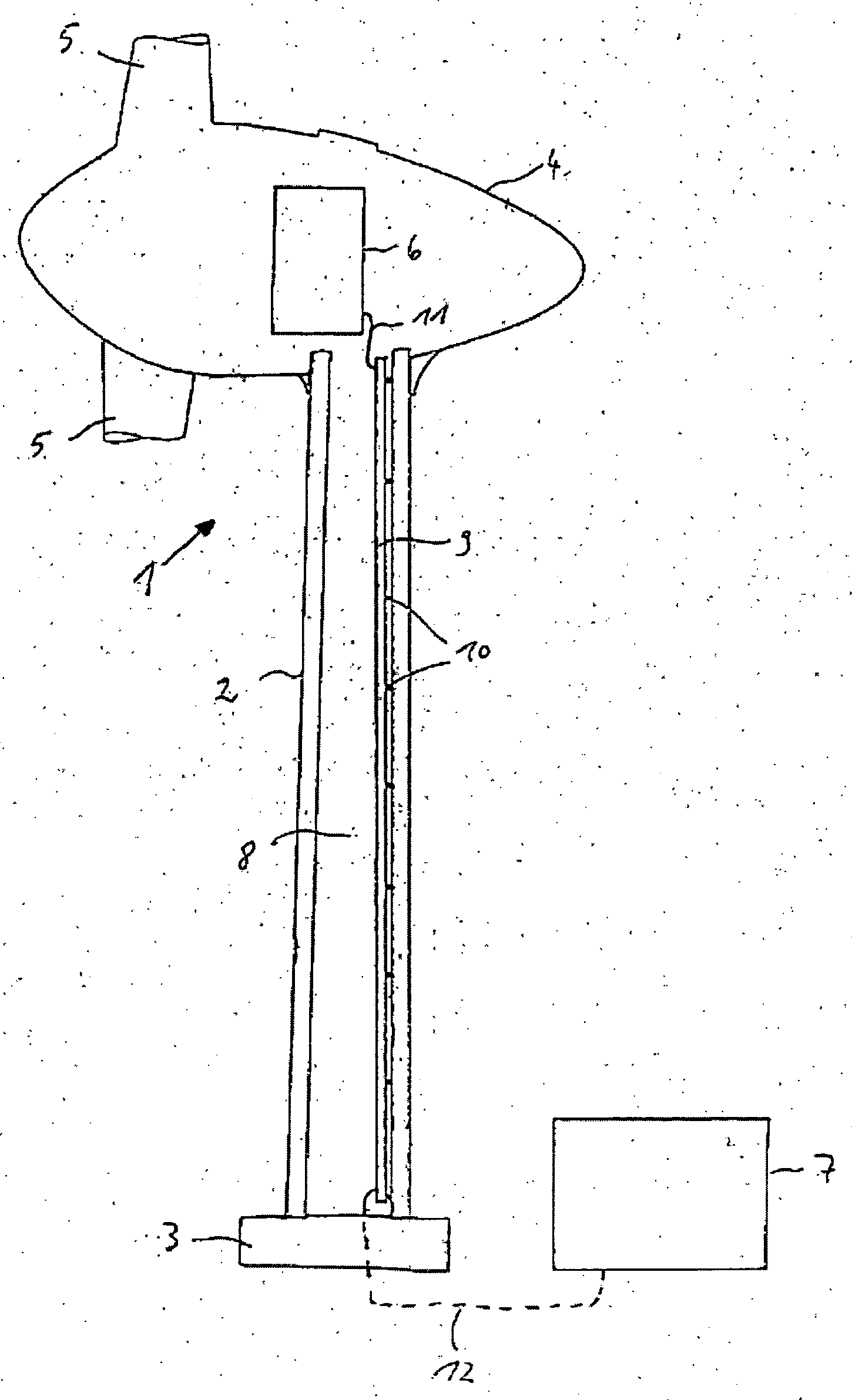

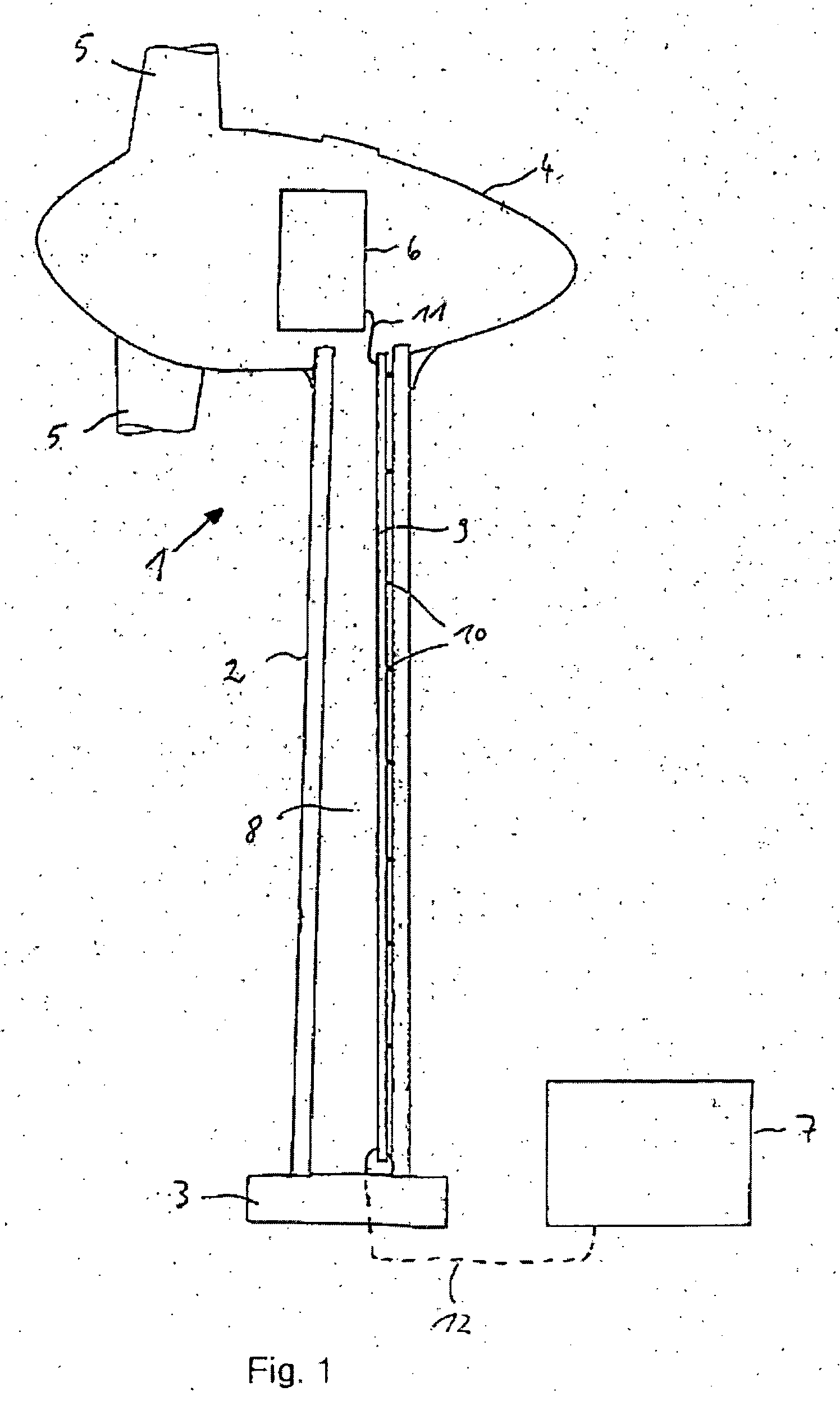

[0026] The wind-power system 1 shown schematically in FIG. 1 and described in German Pat. No. 10 152 557 has a tower 2 with a foundation 3, a gondola 4 supported so that it can rotate in the region of the top of the tower, as well as a power module 7 arranged in the region of the tower base, for example, in a small, separate housing. Within the gondola 4, there is a rotor supported so that it can rotate about a horizontal axis with several rotor blades 5, as well as an electrical generator 6. The rotor is set in rotation by the force of wind acting on the rotor blades 5 and drives the generator 6 for generating electrical power.

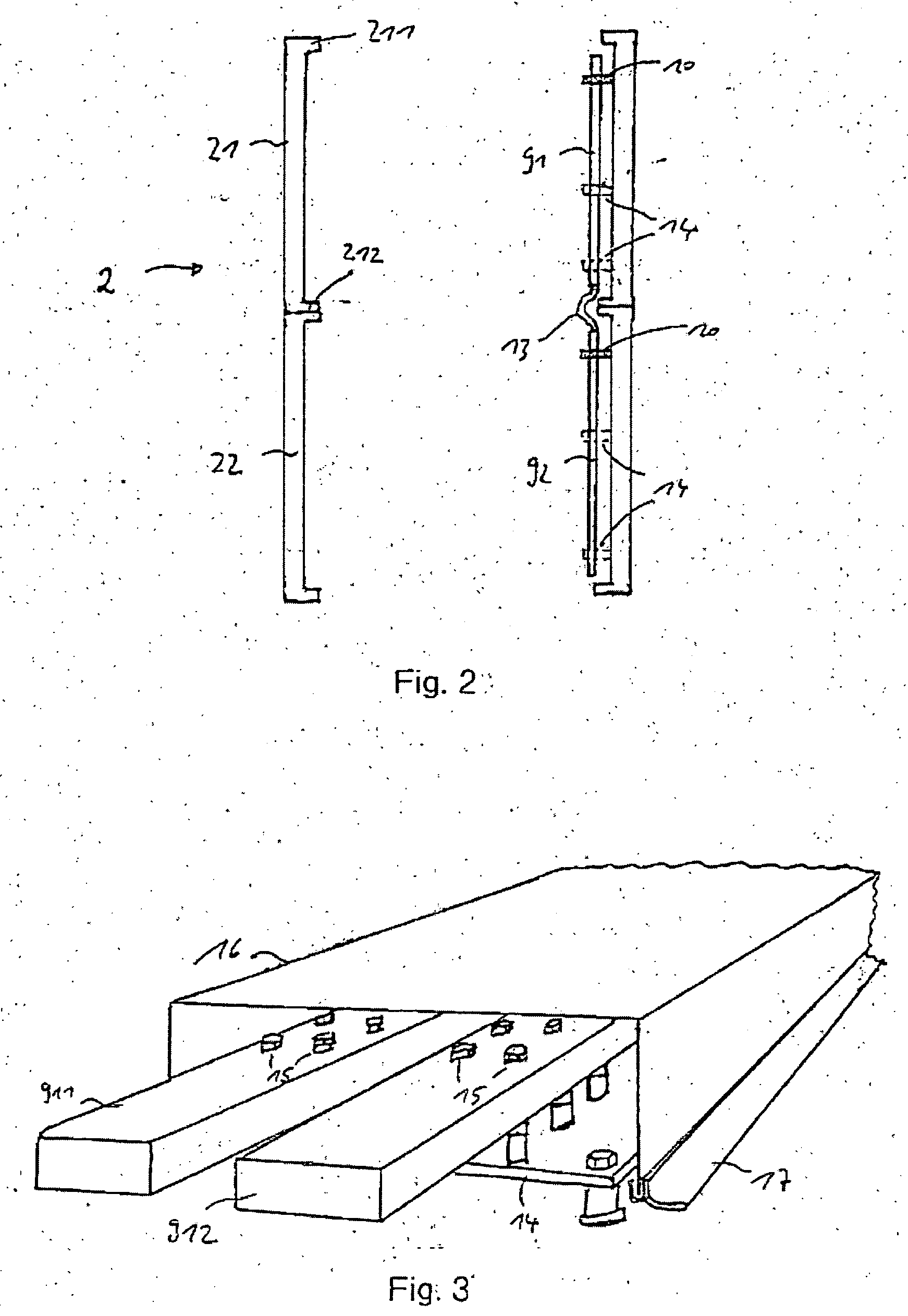

[0027] For transmitting the energy generated by the generator 6 to the power module 7, which has numerous electrical units, such as a transformer or optionally a rectifier for further processing of the electrical power before it is fed into the power network or transmitted to a load, according to the invention, there are busbars, preferably two busbars, atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com