Housing for the nacelle of a wind turbine

a wind turbine and nacelle technology, applied in the direction of machines/engines, liquid fuel engines, final product manufacturing, etc., can solve the problems of large geometric tolerance, large size of components, and associated large impurity, and achieve the effect of low production cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

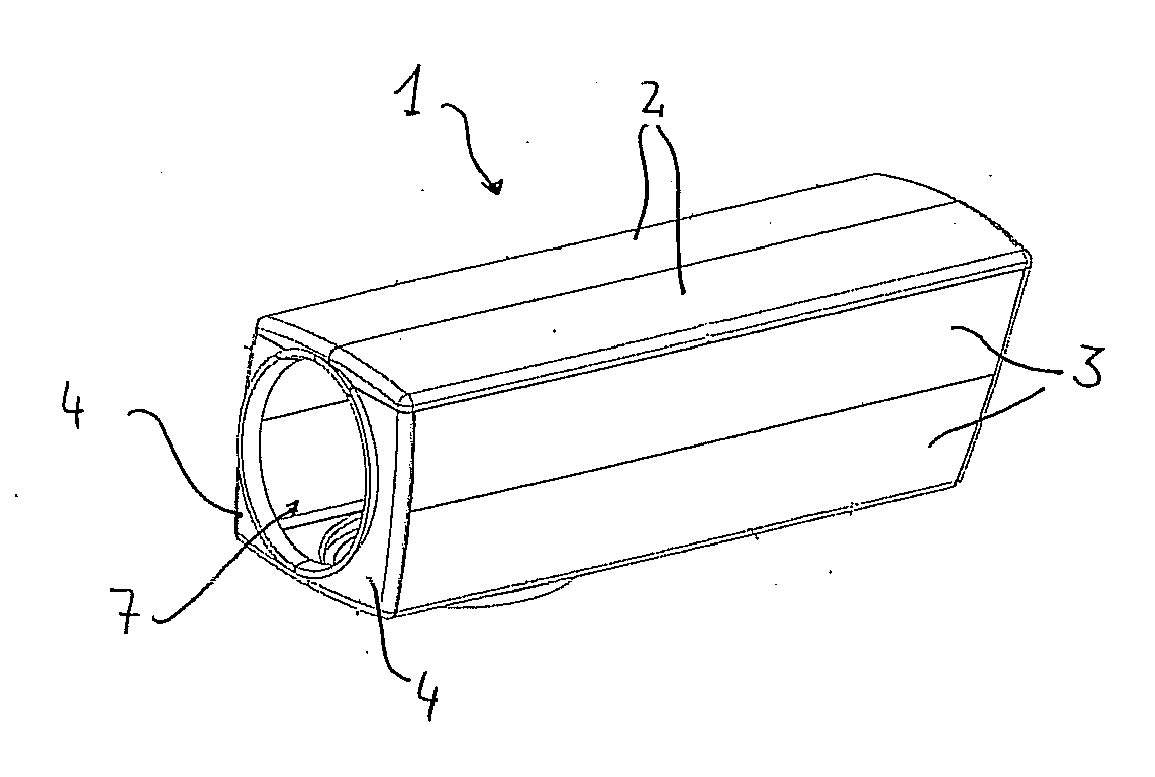

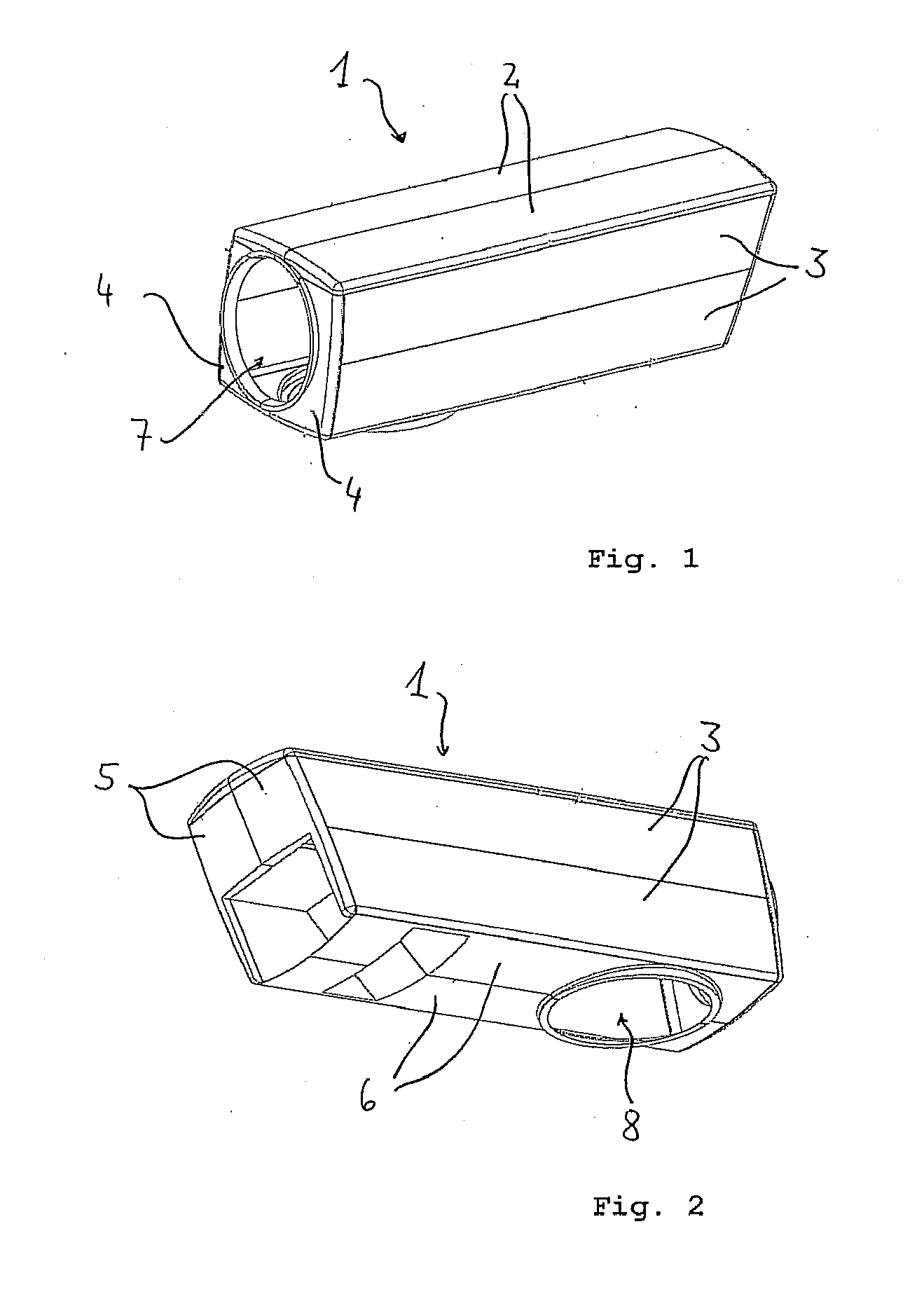

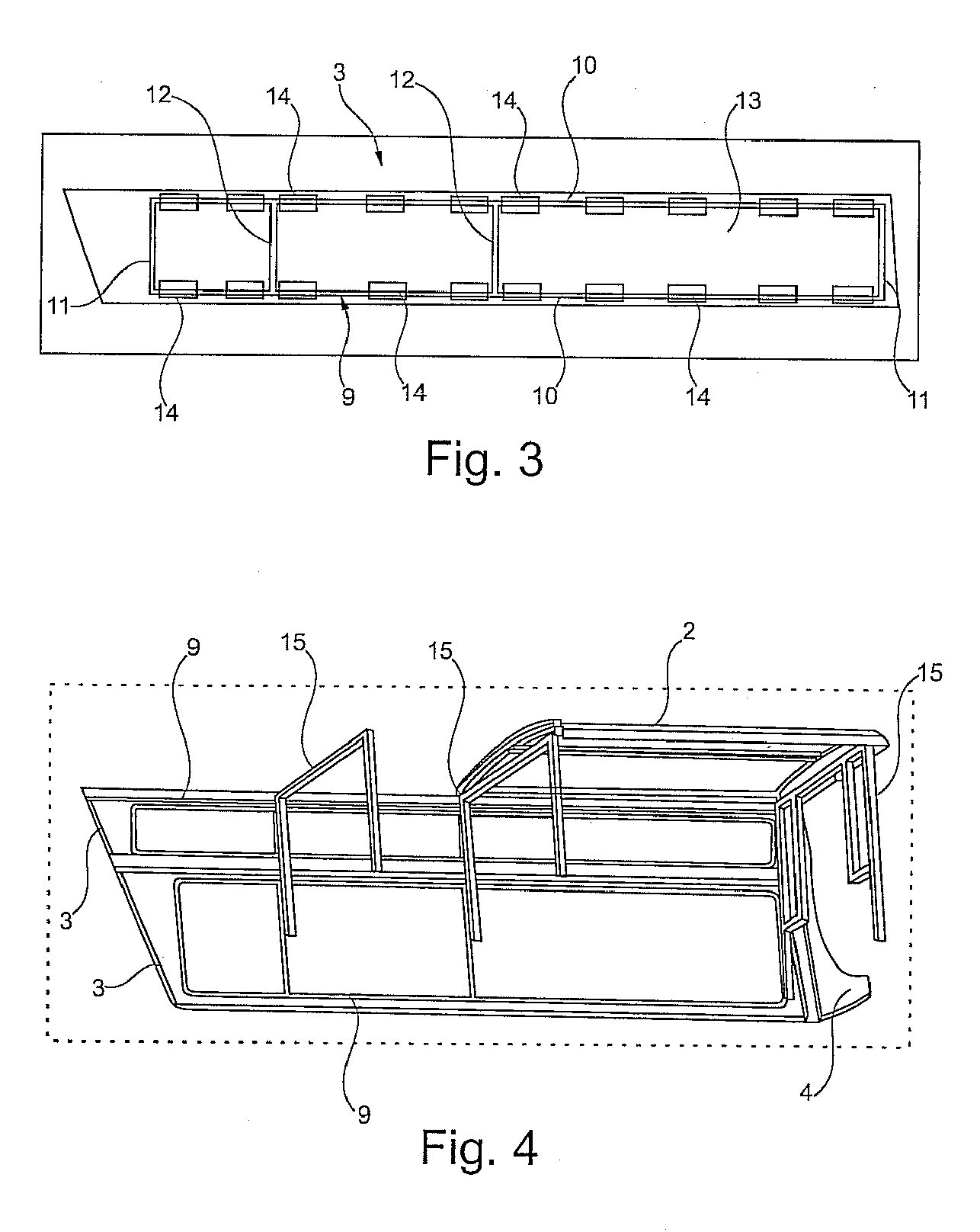

[0045]In the drawings, in schematic basic views that are not to scale, individual views are shown of one exemplary embodiment for a housing of the invention for the nacelle of a wind turbine. These drawings and the description below of the exemplary embodiment shown in them are intended to promote understanding of the invention in its general scope and are not limiting.

[0046]In FIGS. 1 and 2, the basic construction of a housing 1, constructed according to the invention from one support structure and a plurality of covering segments, for the nacelle of a wind turbine is shown in two different views. The housing 1 may also be called a machine house covering. On a support frame, not shown in detail in these drawings, a total of twelve covering segments are disposed and affixed; they are embodied as self-supporting and together form the housing 1. These segments are divided up into two ceiling segments 2, which as elongated components extend over the entire length of the housing 1 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com