Method And Apparatus For Removing Liquids From Wells

a well and fluid technology, applied in the direction of positive displacement liquid engine components, liquid fuel engine components, positive displacement pump components, etc., can solve the problems of reducing gas production, halting gas production, and reducing reservoir pressure and gas velocities, so as to reduce gas production and reduce gas production. , the effect of efficient fluid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

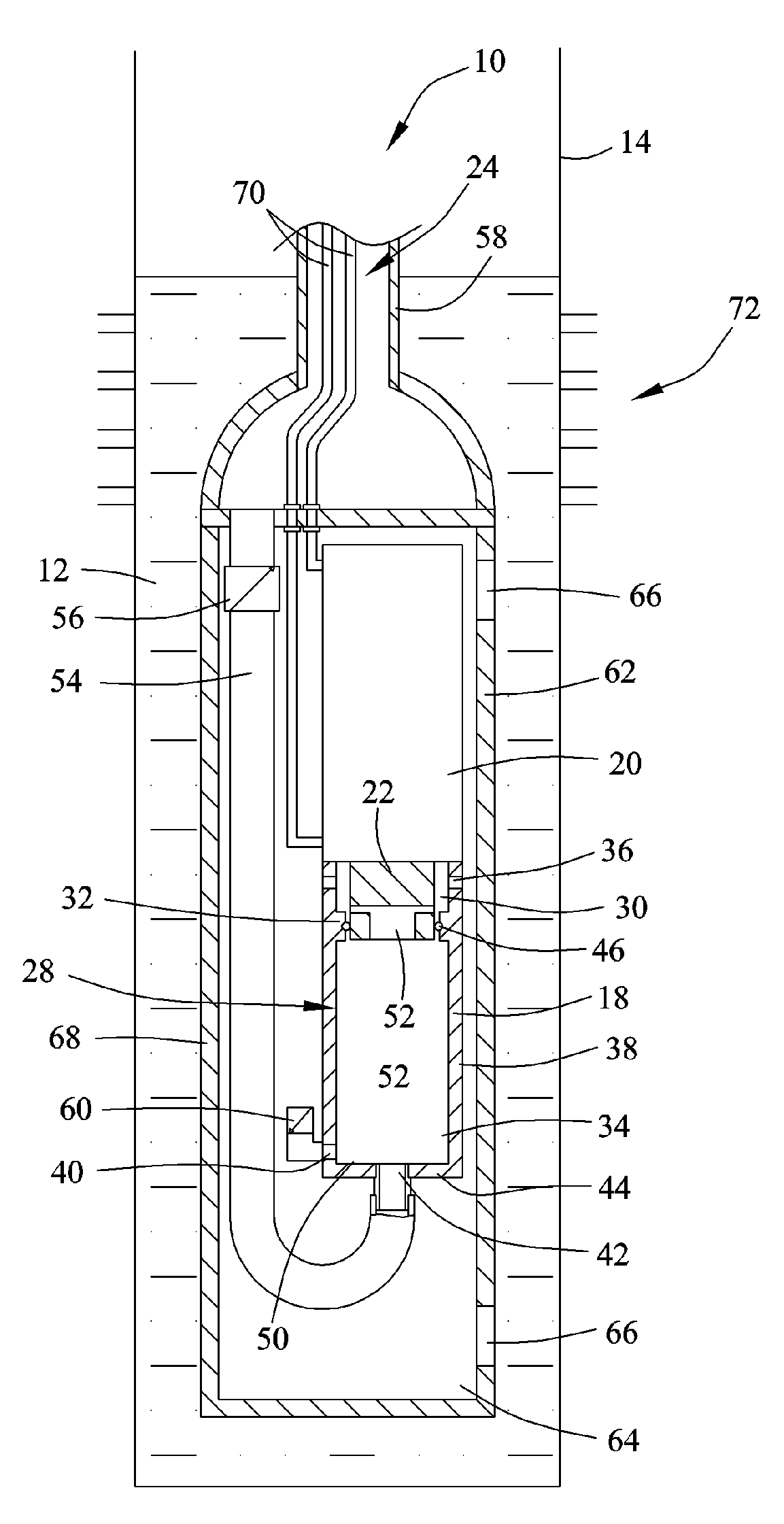

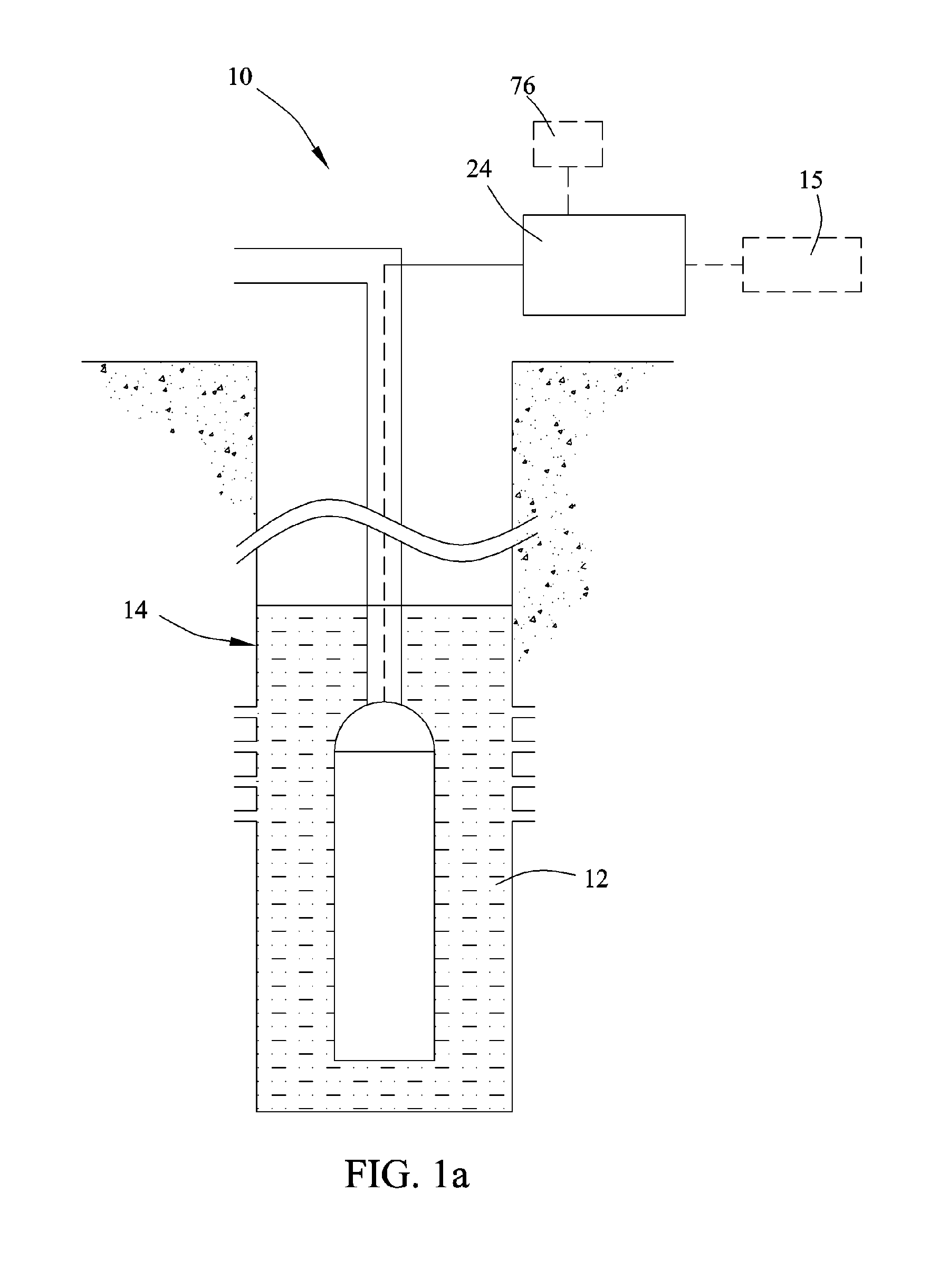

[0025] Referring now to the drawings, and particularly to FIGS. 1a-3b, a preferred embodiment of the pump apparatus 10 is illustrated. With reference to FIG. 1a, the pumping apparatus 10 is employed to lift formation fluid 12 from the well 14 to “unload” the well and restore it back to flow production. The formation fluid 12 can be water, oil or any other liquid gas mixture which is present downhole the well 14 to be pumped from one location to another. In addition, while the pump apparatus 10 is shown to be lifting the formation fluid 12 from a conventional gas well 14, the pump apparatus 10 will work as well in any other environment where its particular features would be beneficial.

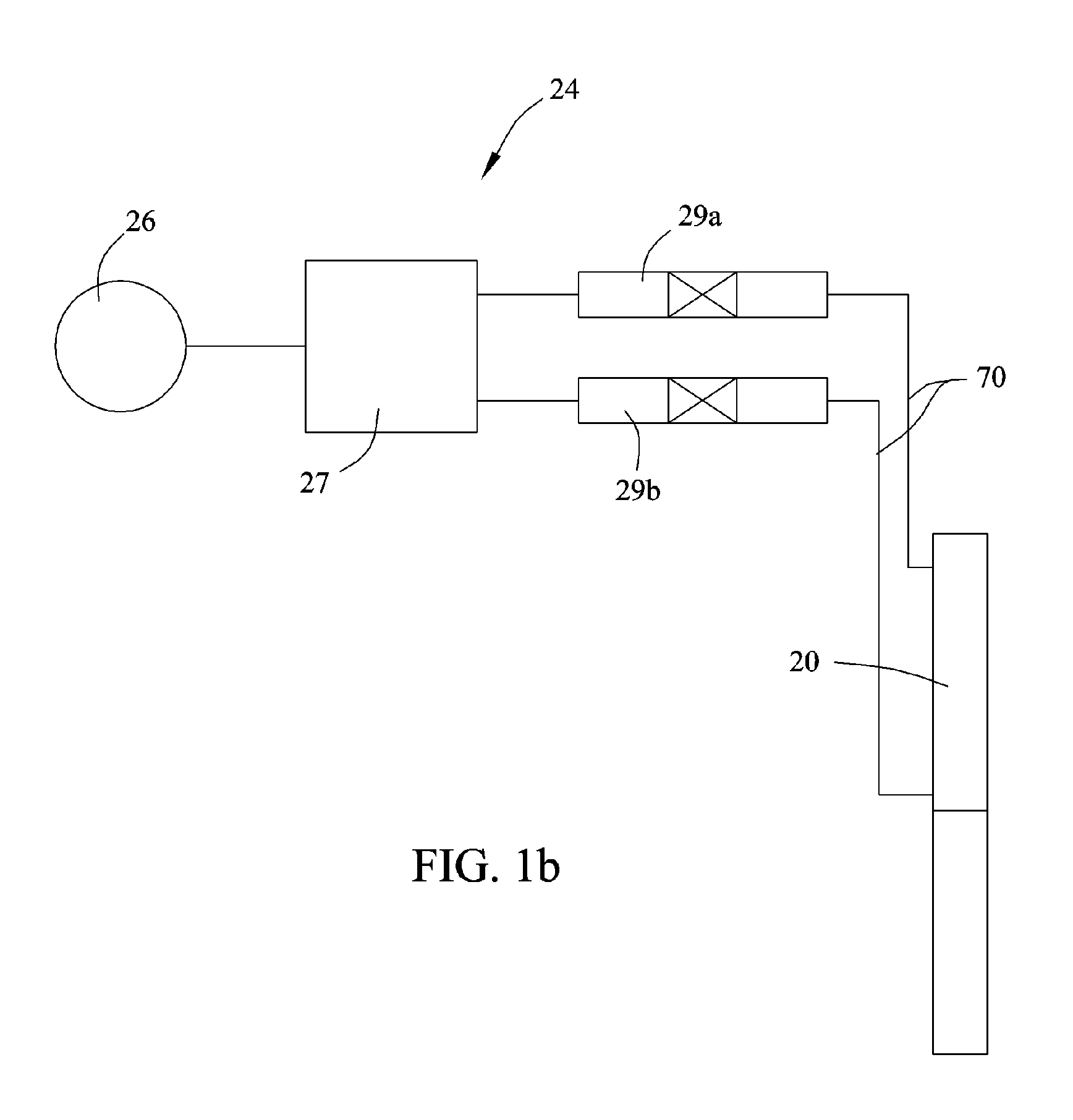

[0026] The pump apparatus 10 essentially includes a pump body 18, a hydraulic head 20 connected to the pump body, a reciprocating displacement plunger 22 connected to and operated by the hydraulic head 20 to reciprocate within the pump body to draw-in formation fluid 12 and displace it from the pump bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com