Interlocking system for waney lumber

a technology of interlocking system and waney lumber, which is applied in the direction of load-supporting elements, structural elements, building components, etc., can solve the problems of difficult if not impossible incorporation of waney lumber into composite wood products, and achieve the effects of less glue lines, reduced adhesive consumption, and high cost of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

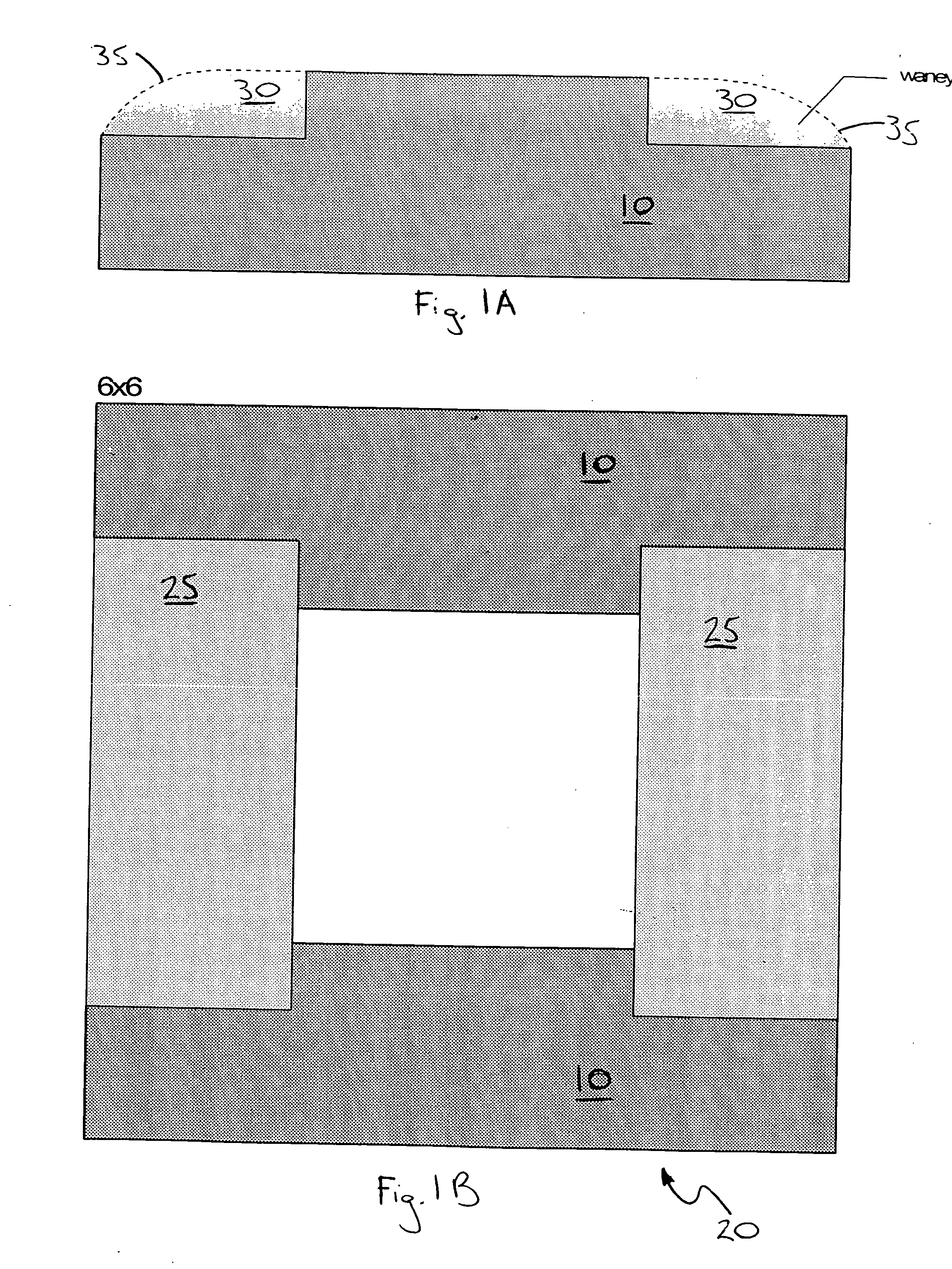

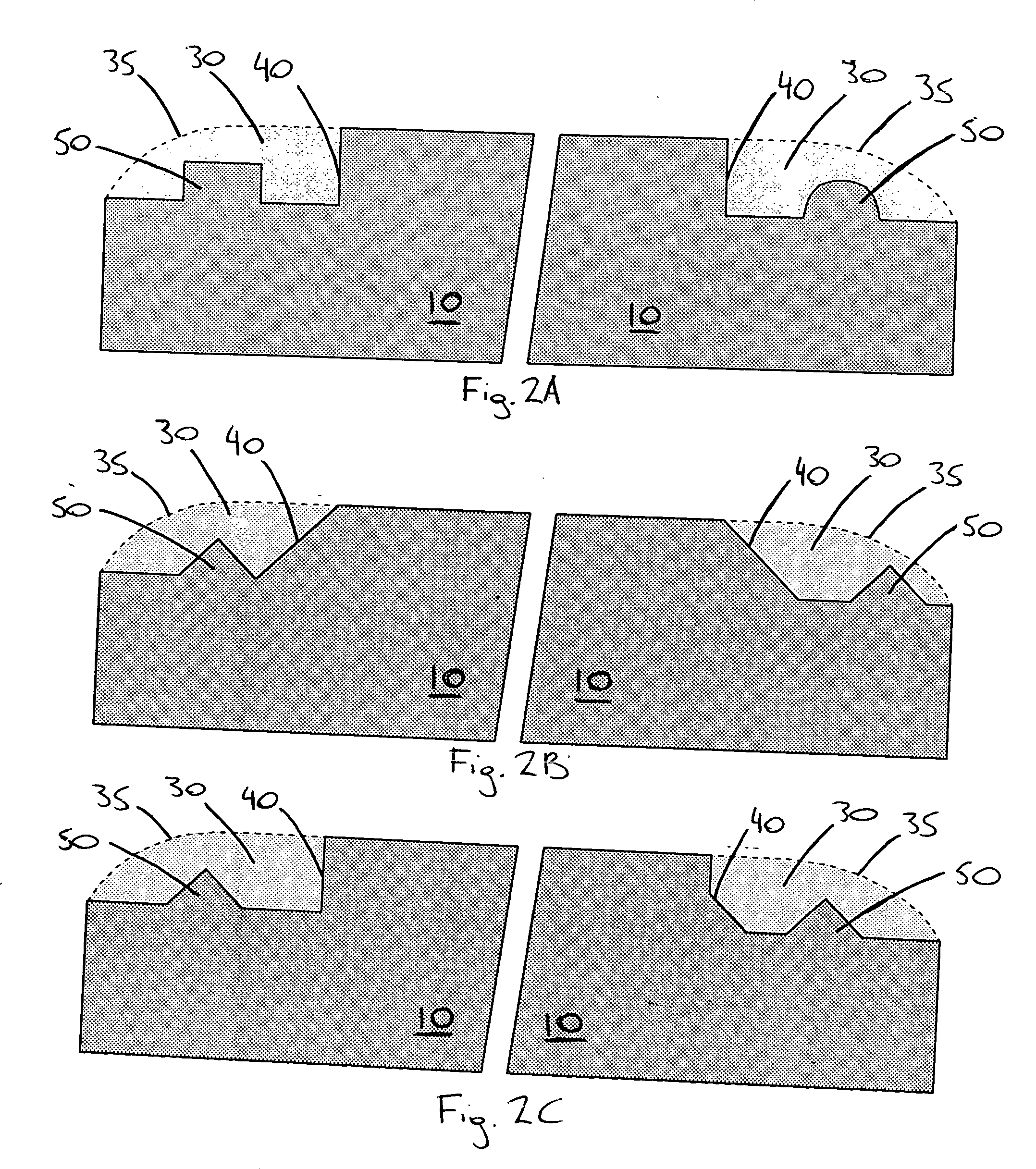

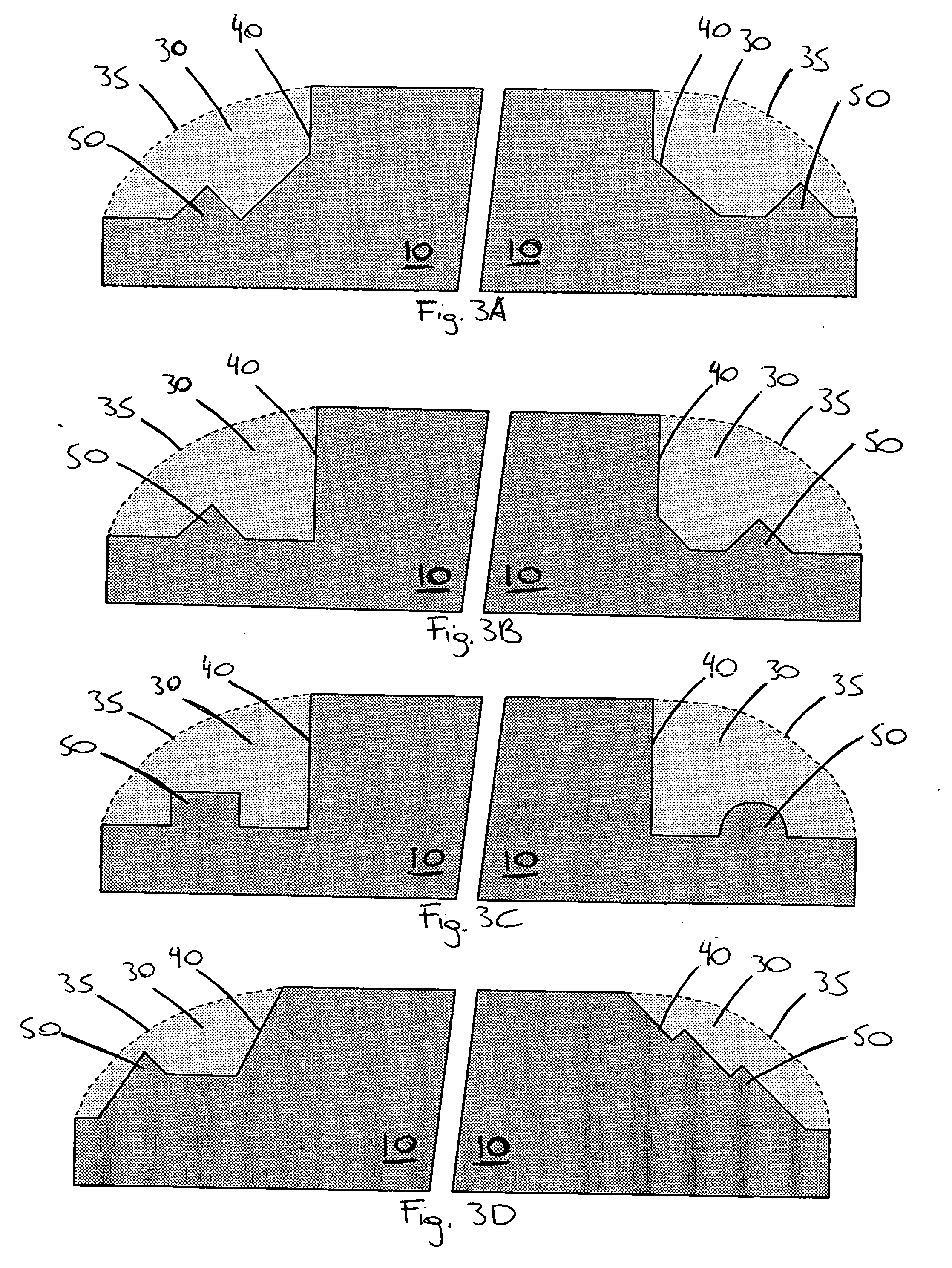

[0036]FIGS. 1A and 1B illustrate the basic concept of the present invention in that an elongated piece of waney lumber is profiled to produce a profiled elongated piece of lumber 10. In the profiling process waney portions or edges 30 are removed from the original waney lumber (the dotted line indicates the outline 35 of the original waney lumber). The rounded, irregular surface 35 of the waney portion 30 makes it unsuitable for use in the manufacture of composite products because it is not possible to achieve a strong and uniform bond between the surface of the waney lumber and other components of the composite products. The profiling process provides indented portions 40 which allow the profiled lumber 10 to have uniform contact with adjacent pieces of lumber. The profiling process also allows more of the waney lumber fiber to be used for the composite construction than would be the case if it was simply squared. The hollow core composite beam 20 in FIG. 1B is made from two 2×4's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com