Acoustic liner use of such a liner and method for manufacturing an acoustic liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

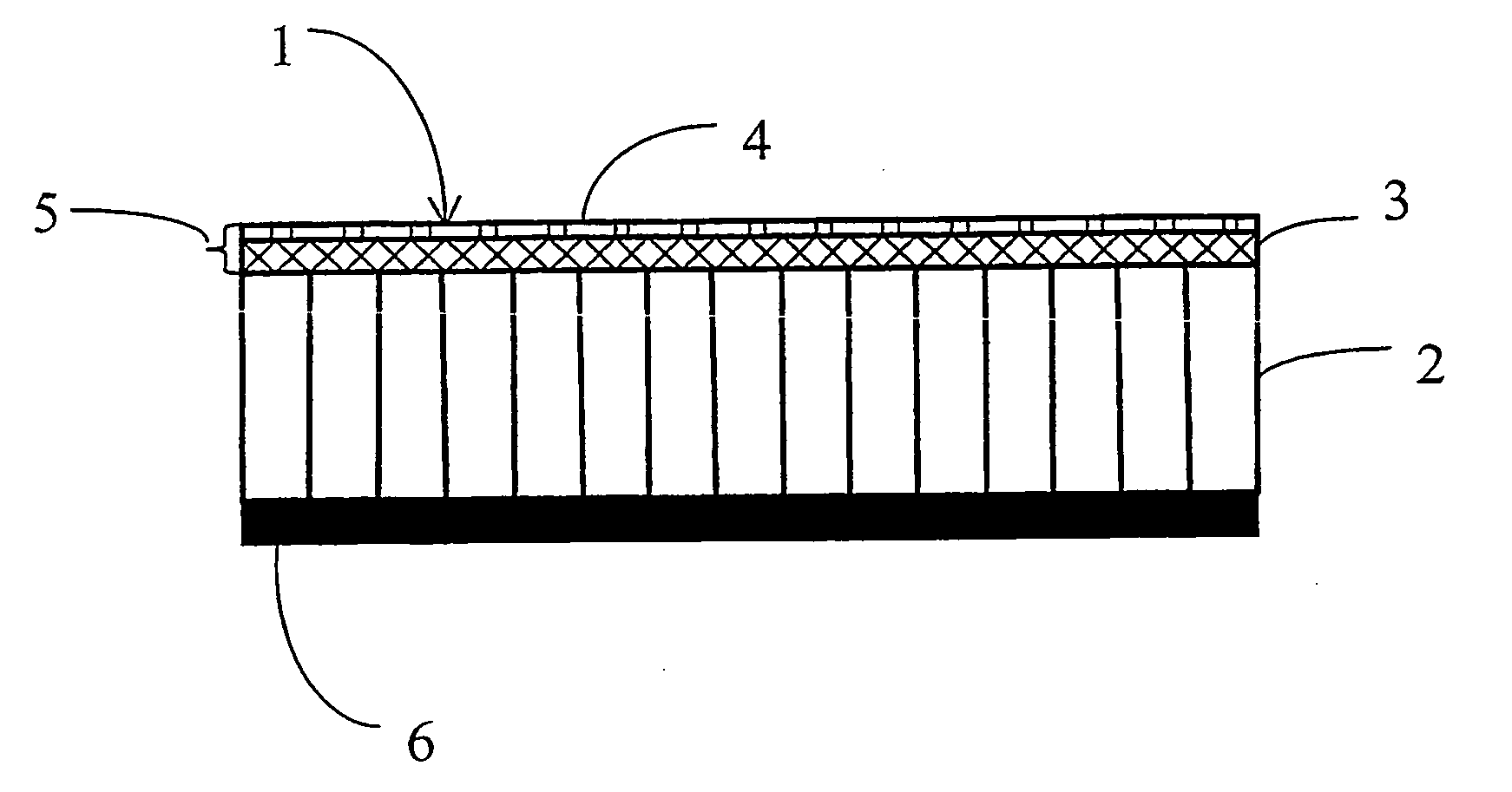

[0020] In the figure, a panel 1 is shown in the form of an acoustic liner. The panel 1 is designed to withstand hot stream environments and therefore can be used as a noise absorber for example in aircraft engine outlets. The panel also can be used in other hot environments such as in gas turbine applications.

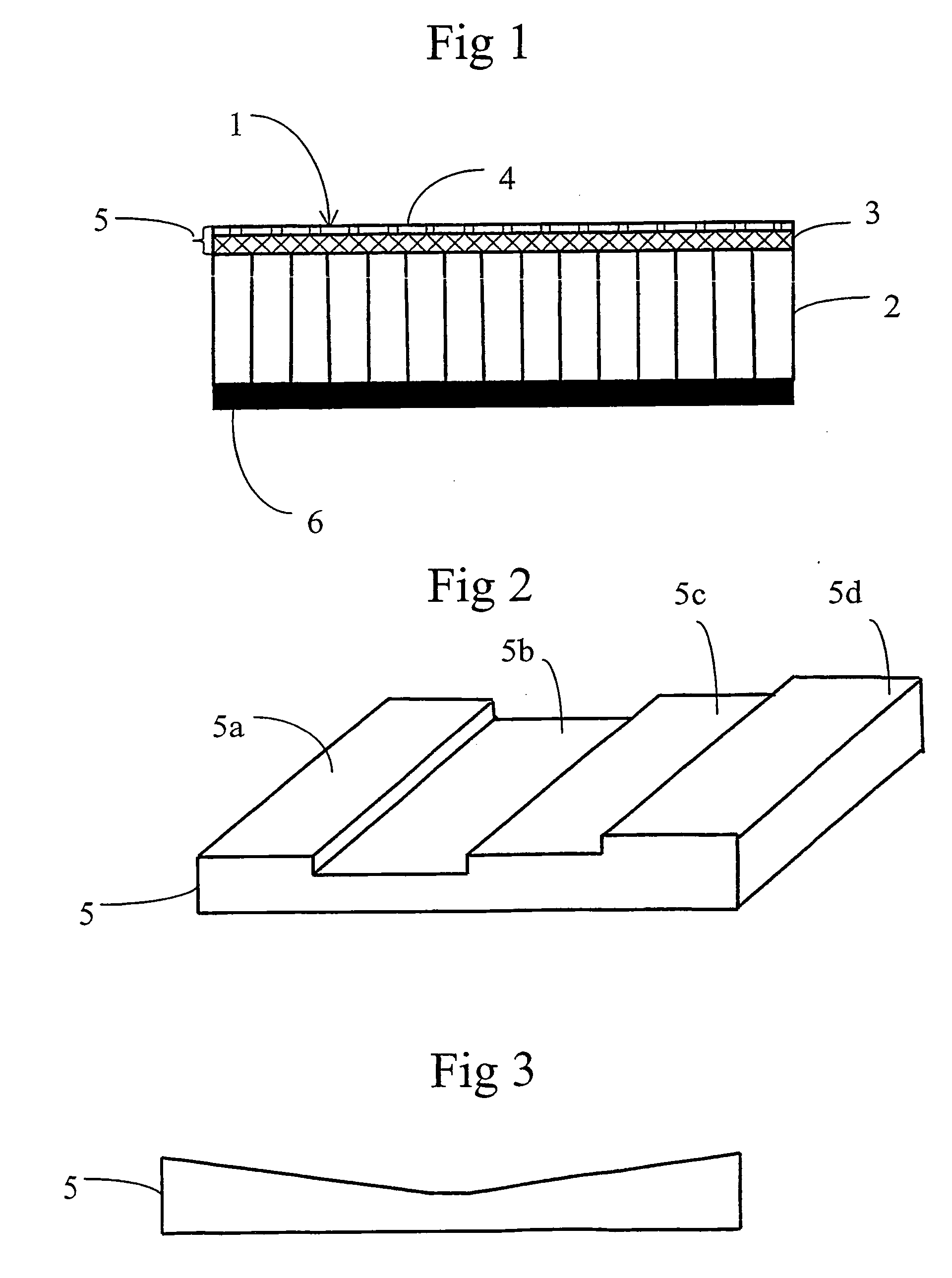

[0021] The panel 1 comprises a liner core 2 and a top sheet assembly 5. The core 2 is attached to a solid backing sheet 6, which is impervious. The top sheet assembly 5 includes a layer 3 of a metallic foam and a perforated sheet 4. The liner core 2 is for example a conventional honeycomb core made of Titanium, Nickel or Chromium, or an alloy including one or more of said metals. However, the honeycomb core can be made of any metal or metal alloy withstanding the hot stream environment (typically about 700° C. of an aircraft engine). Alternatively, the line core 2 can be made of a metallic foam. Metallic foams will be described more in detail below. The thickness of the liner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com