Light emitting diode device

a technology of light-emitting diodes and led devices, which is applied in semiconductor devices, semiconductor/solid-state device details, electrical devices, etc., can solve the problems of increasing the height of the electronic components mounting board, increasing the cost of the printed wire board, and the above-described related art led devices cannot be typically mounted on the same surface of a single-sided board on which to surface-mount electronic components, etc., to achieve efficient condense light, reduce the size of the led devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

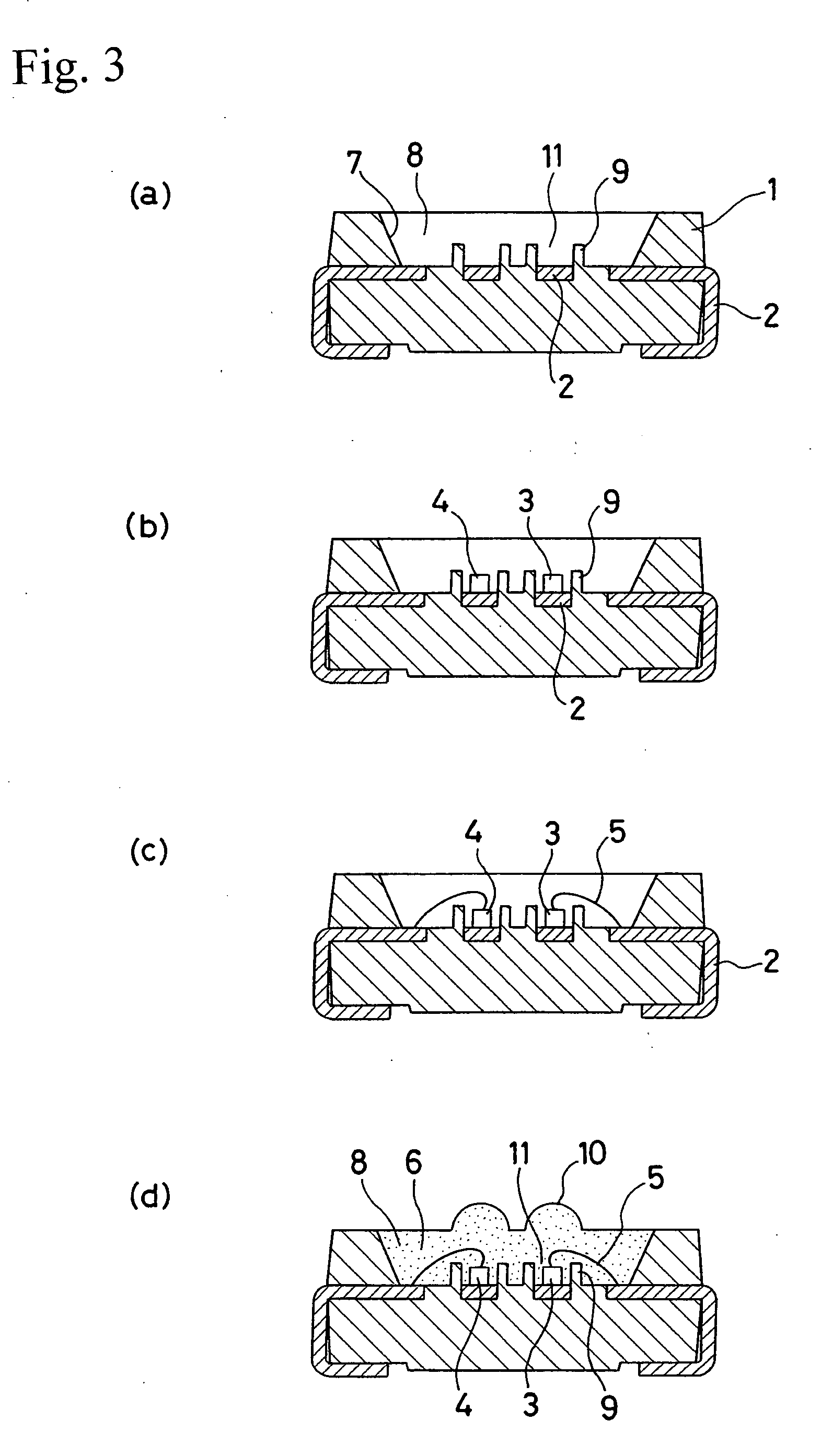

[0050] Various exemplary embodiments of this invention will now be described with reference to FIGS. 1-8 in detail (using the same reference numerals to denote the same or similar parts). The embodiments described below are examples of the invention and are given various technical features. However, the scope of the invention is not limited to these embodiments.

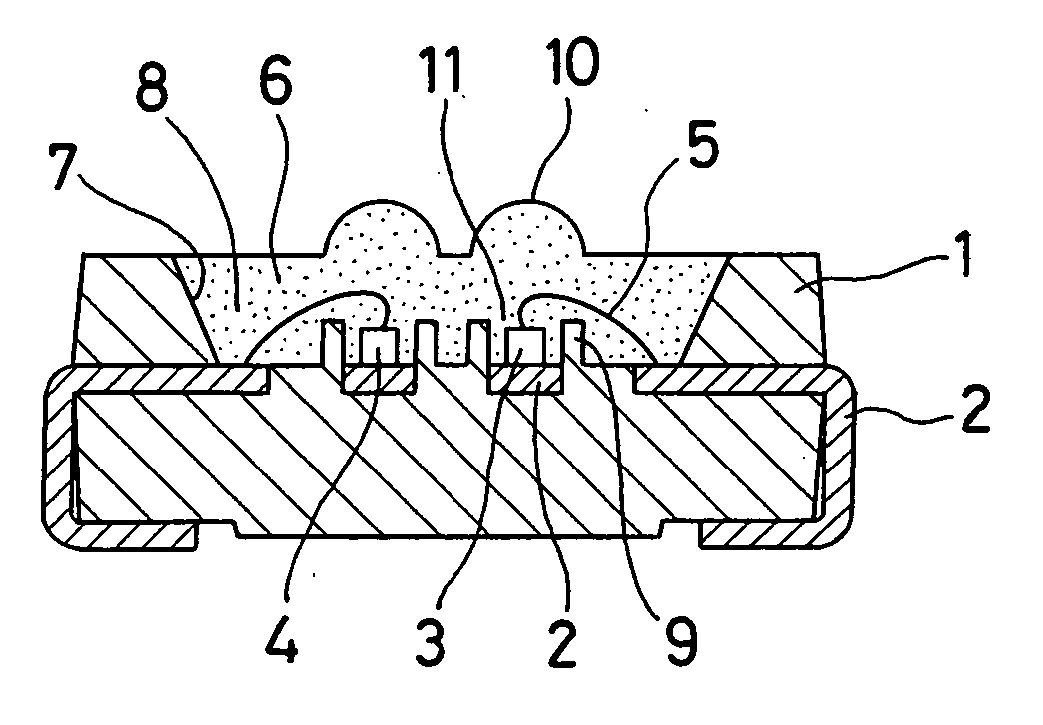

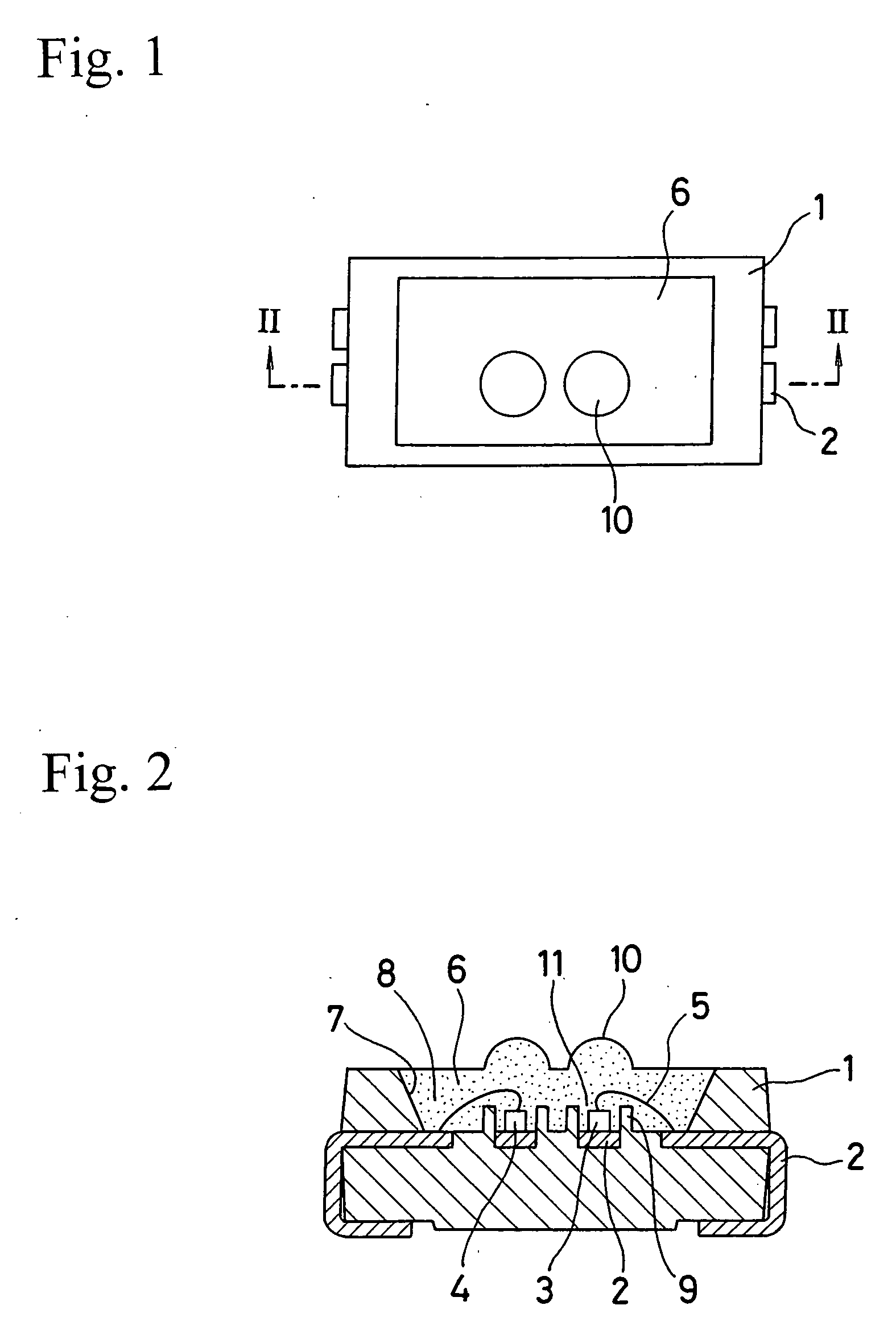

[0051]FIG. 1 is a top view illustrative of an embodiment of an LED device made in accordance with the principles of the invention. FIG. 2 is a cross-sectional view taken along line II-II of FIG. 1. This embodiment is directed to an LED device of the so-called surface-mount type, which includes a reflector 1, a lead frame 2, a red LED chip 3, a green LED chip 4, a bonding wire 5, and a light transmissive resin 6.

[0052] The LED device including these elements can also include the following structure. Plural separate lead frames 2 can be insert-molded in the reflector 1 composed of a white resin having high reflectivity to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com