Semiconductor test device with heating circuit

a technology of heating circuit and semiconductor circuit, which is applied in the direction of measurement devices, electrical testing, instruments, etc., can solve the problems that the conventional thermal fatigue testing of a semiconductor circuit may become excessively time-consuming, and the reliability of the semiconductor,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

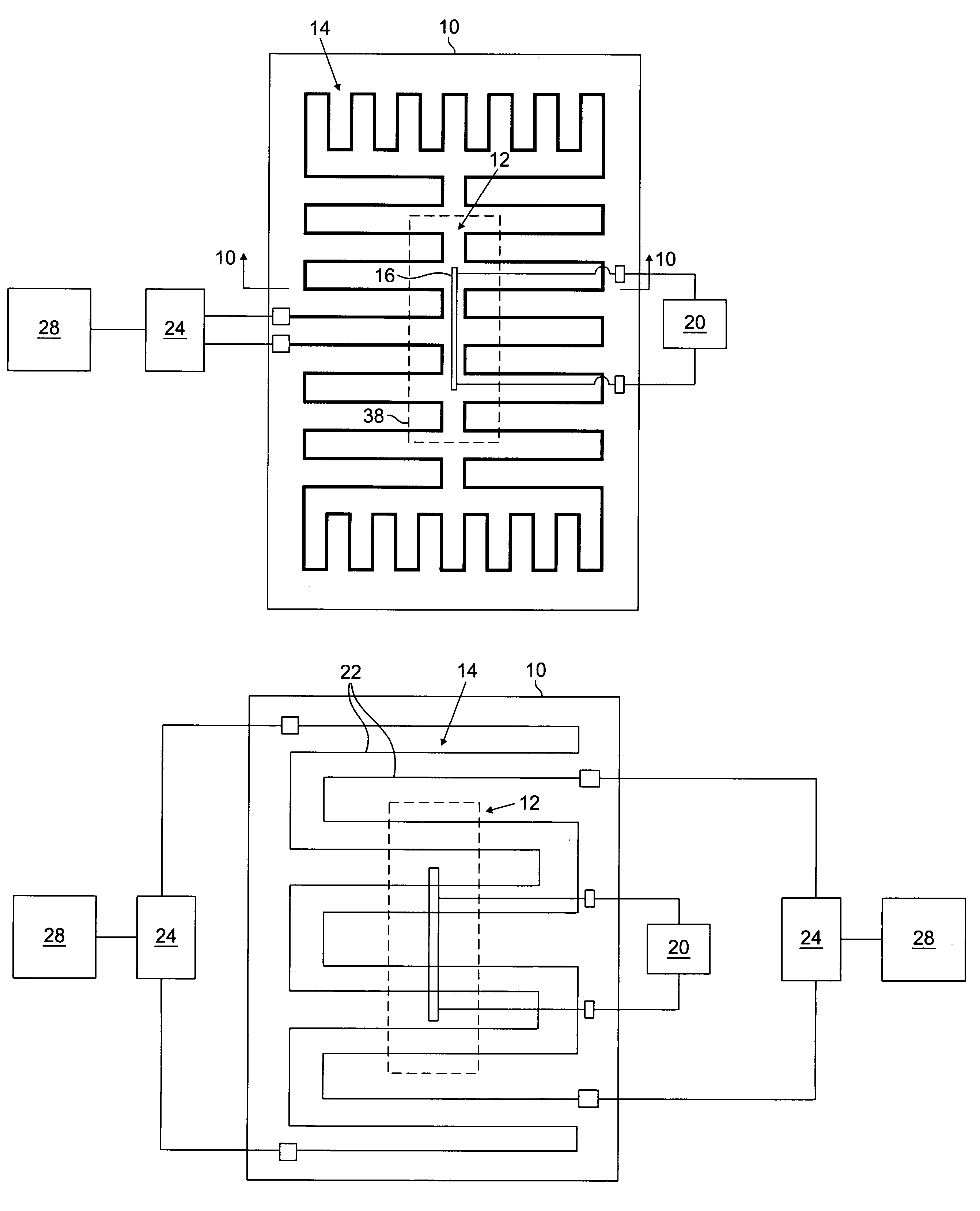

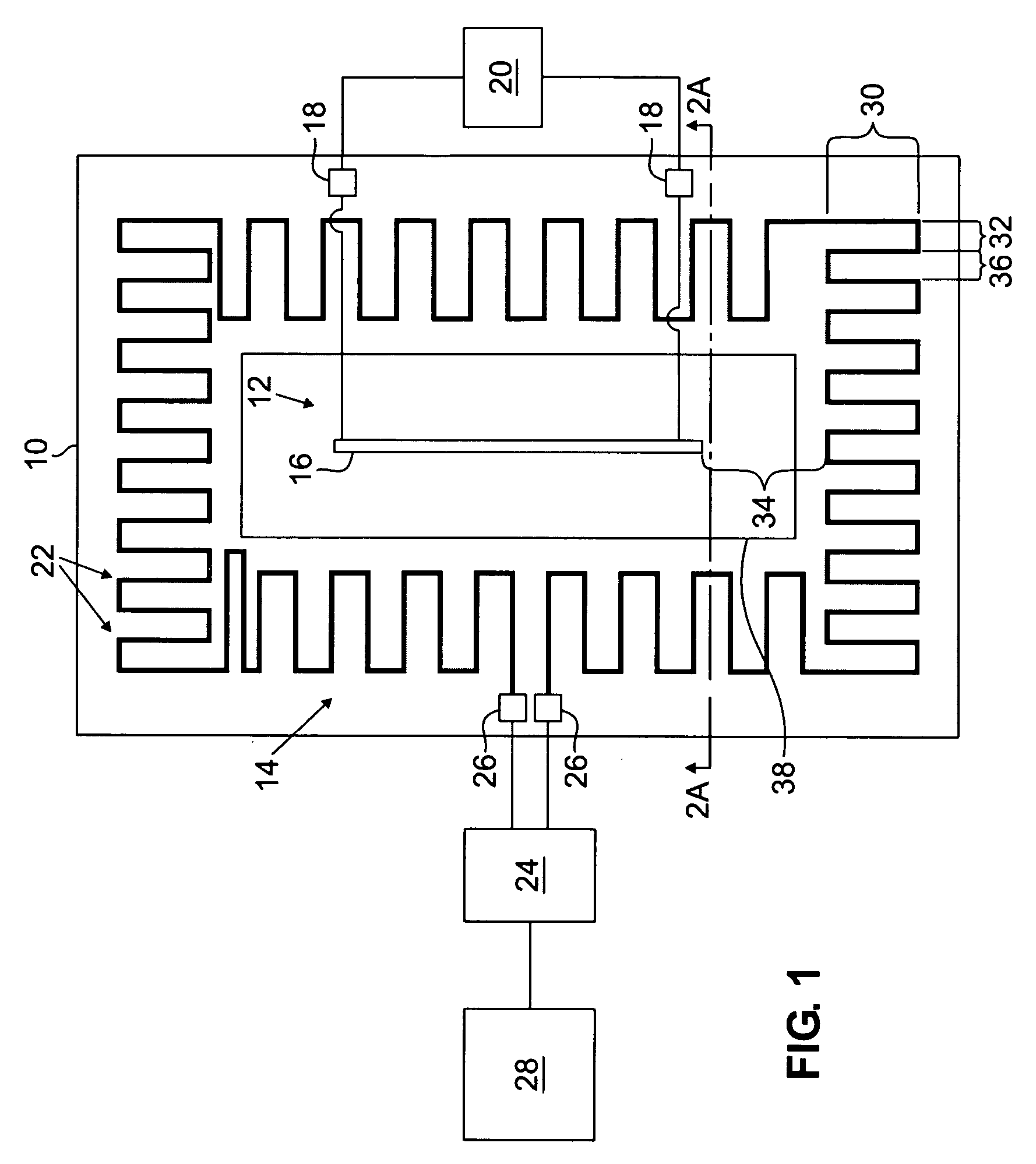

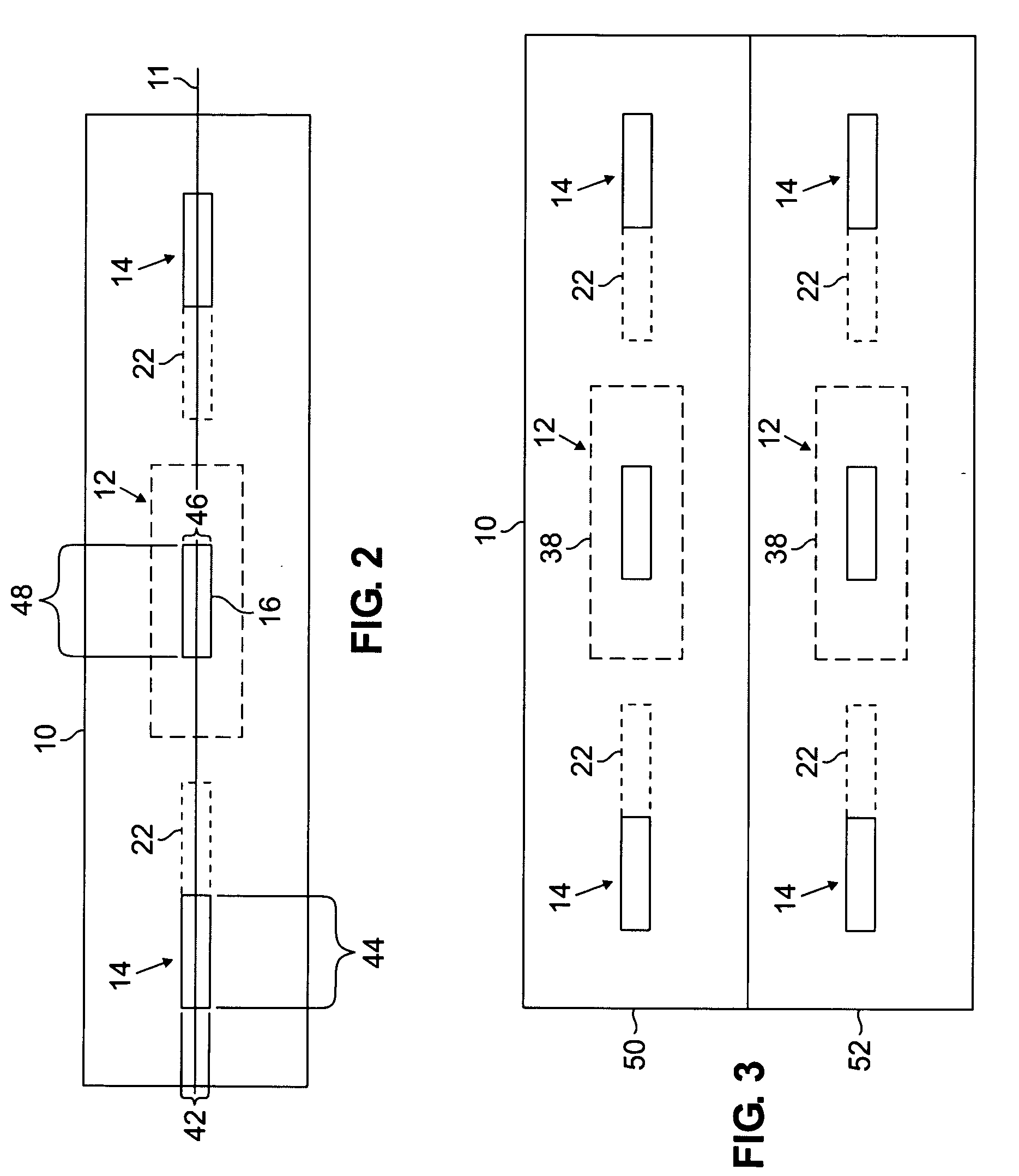

[0018]FIG. 1 shows a top view of an exemplary semiconductor test wafer 10 cut away to reveal a reliability test circuit 12 and an innovative heating circuit 14 integrally formed with the wafer 10 adjacent the reliability test circuit 12. In an aspect of the invention, the reliability test circuit 12 may include a known standard Joint Electron Device Engineering Council (JEDEC) tester, as described in JEDEC standard JESD87, or an extrusion test circuit used to measure metal extrusion phenomena during electro-migration testing, or a similar test structure used to assess interconnect reliability for resistance to electro-migration, stress-induced voiding, or stress migration. In an aspect of the invention, the reliability test circuit 12 may include one or more conductor traces 16 having contacts 18 for applying and measuring electrical signals by a tester 20 connected to the contacts 18. Typically, the conductor trace 16 is disposed coplanar with a horizontal plane of the test circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com