Method of generation of face enveloping gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

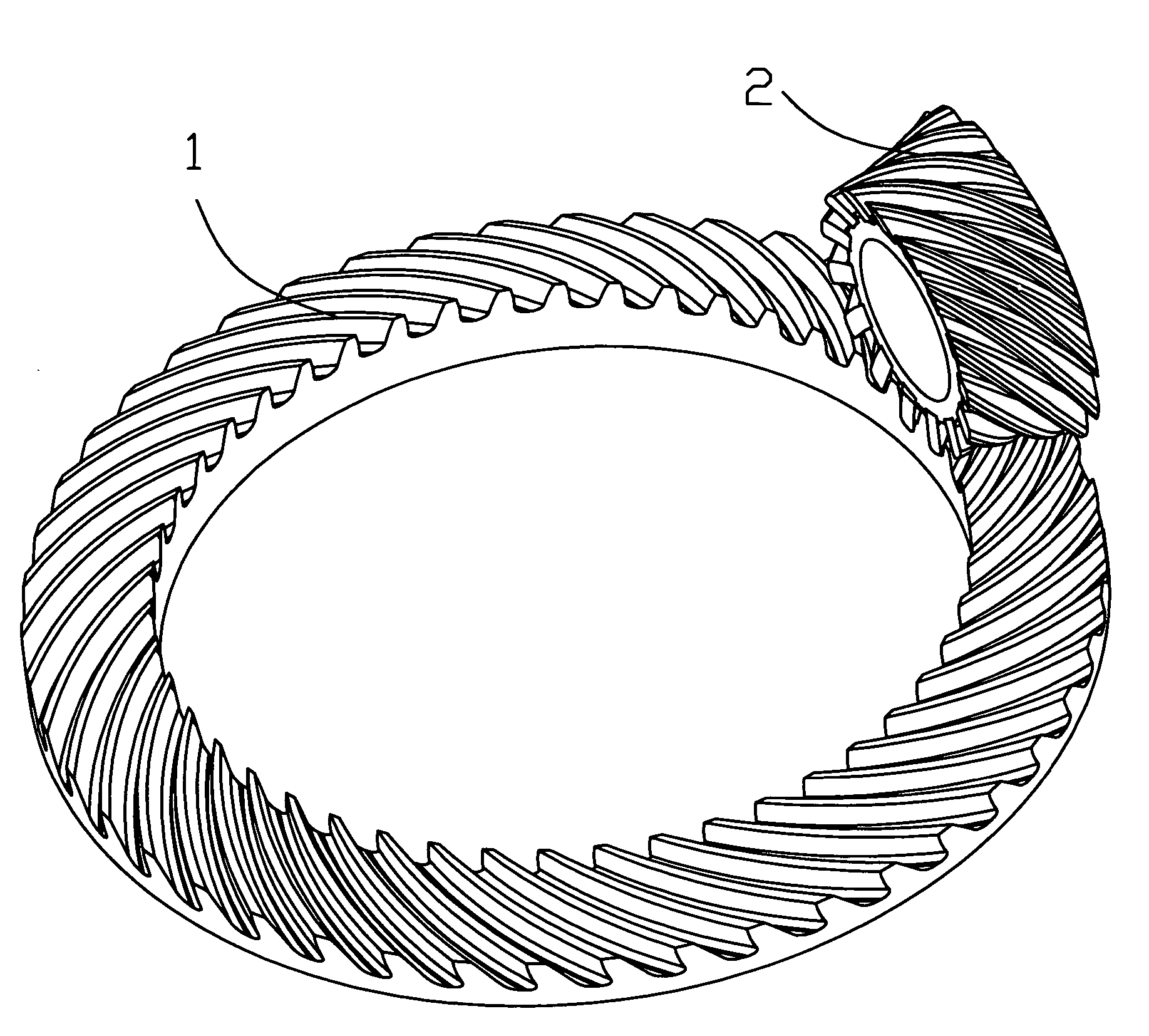

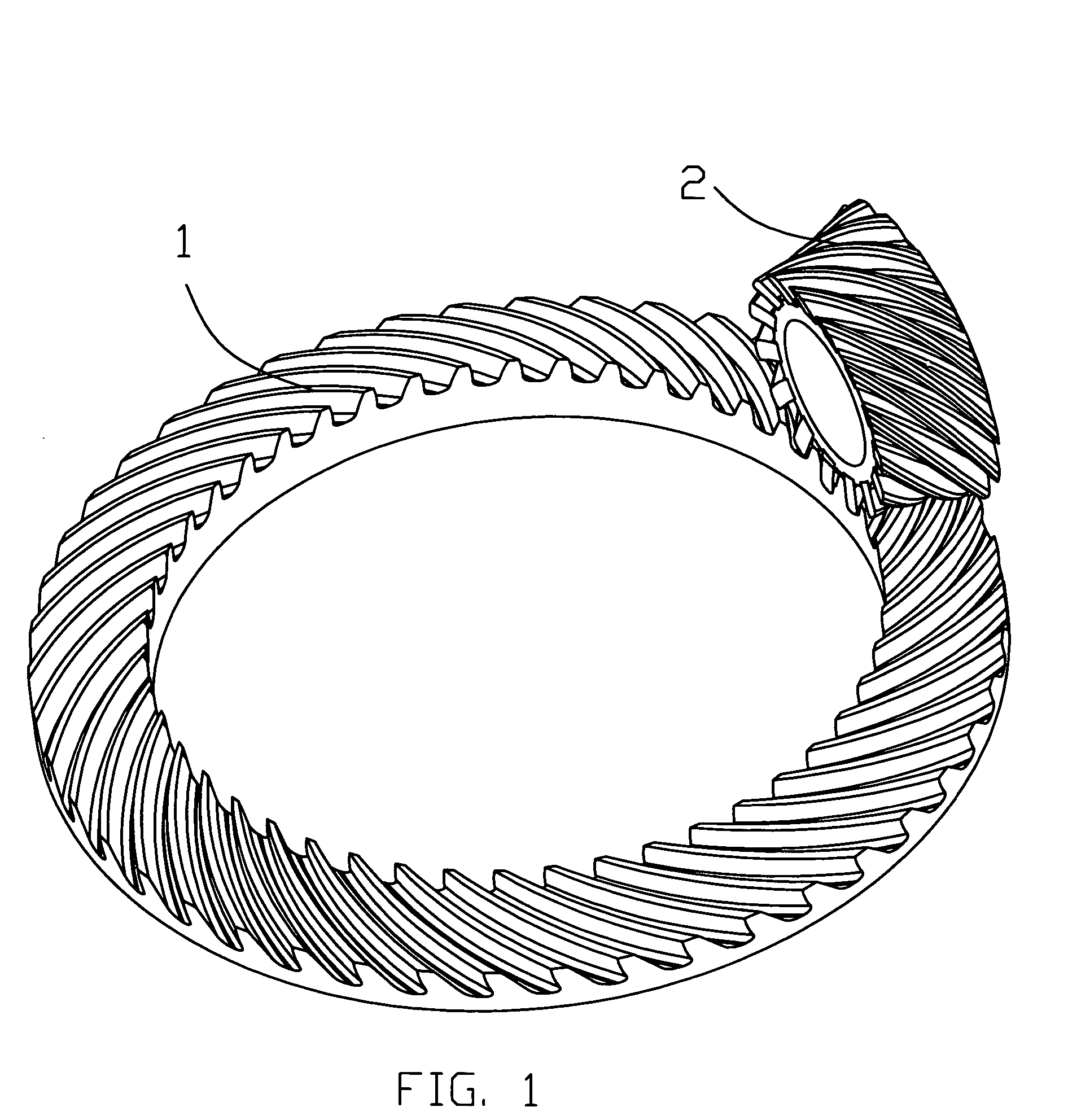

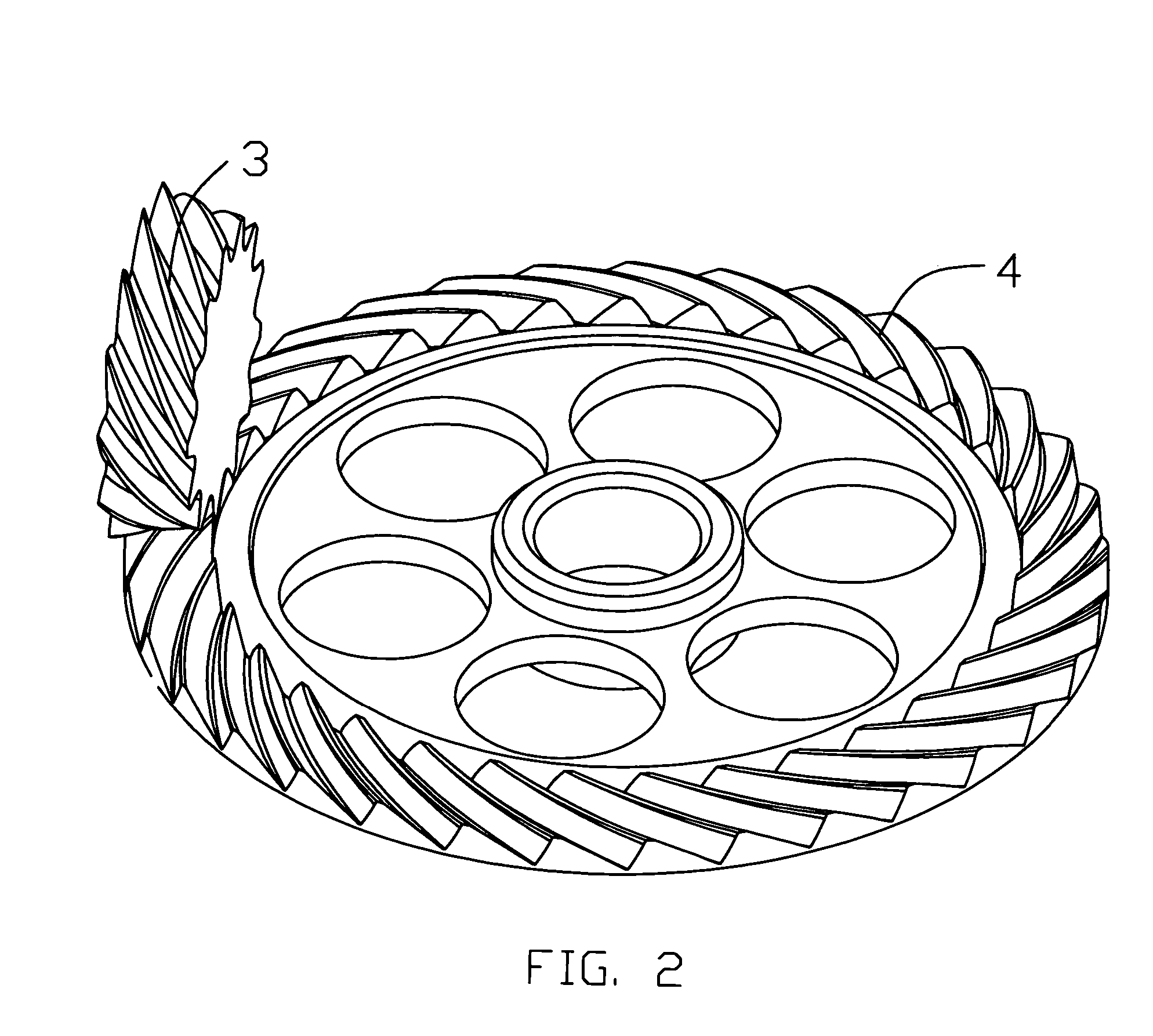

[0043] The following discussion relating to FIGS. 1-22 provides a detailed description of the unique method for manufacturing face enveloping pinion and face gear that can be utilized with the present invention.

[0044]FIG. 1 is an isometric view of face gear 1 in mesh with enveloping worm 2 as a pinion. Face enveloping gears are a new type of right angle gears (U.S. patent application Ser. No. 10 / 435,143 filed May 9, 2003). Said enveloping worm 2 has at least one thread that is engaged by at least one tooth of said face gear 1 wherein said enveloping worm 2 is placed into face arrangement with said face gear 1. In these face enveloping gears the enveloping worm 2 could have any design, however, it is preferred that the enveloping worm is utilized for standard enveloping or double enveloping worm / worm gear transmission. Another name for double enveloping worm / worm gears is globoid gears. Face enveloping gears are using worm threads with less than one revolution or 180 or less degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com