Method of weighted combination specs for enhanced manufacturing yield

a manufacturing yield and combination spec technology, applied in the field of manufacturing processes, can solve the problems of undesired skew (weight) of some performance parameters over others, low hga component yield, and no systematic approach to address the interdependence of those spec parameters, so as to enhance the downstream product yield and performance without significantly affecting the yield of components, and enhance the yield of components without significantly affecting the yield of downstream products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

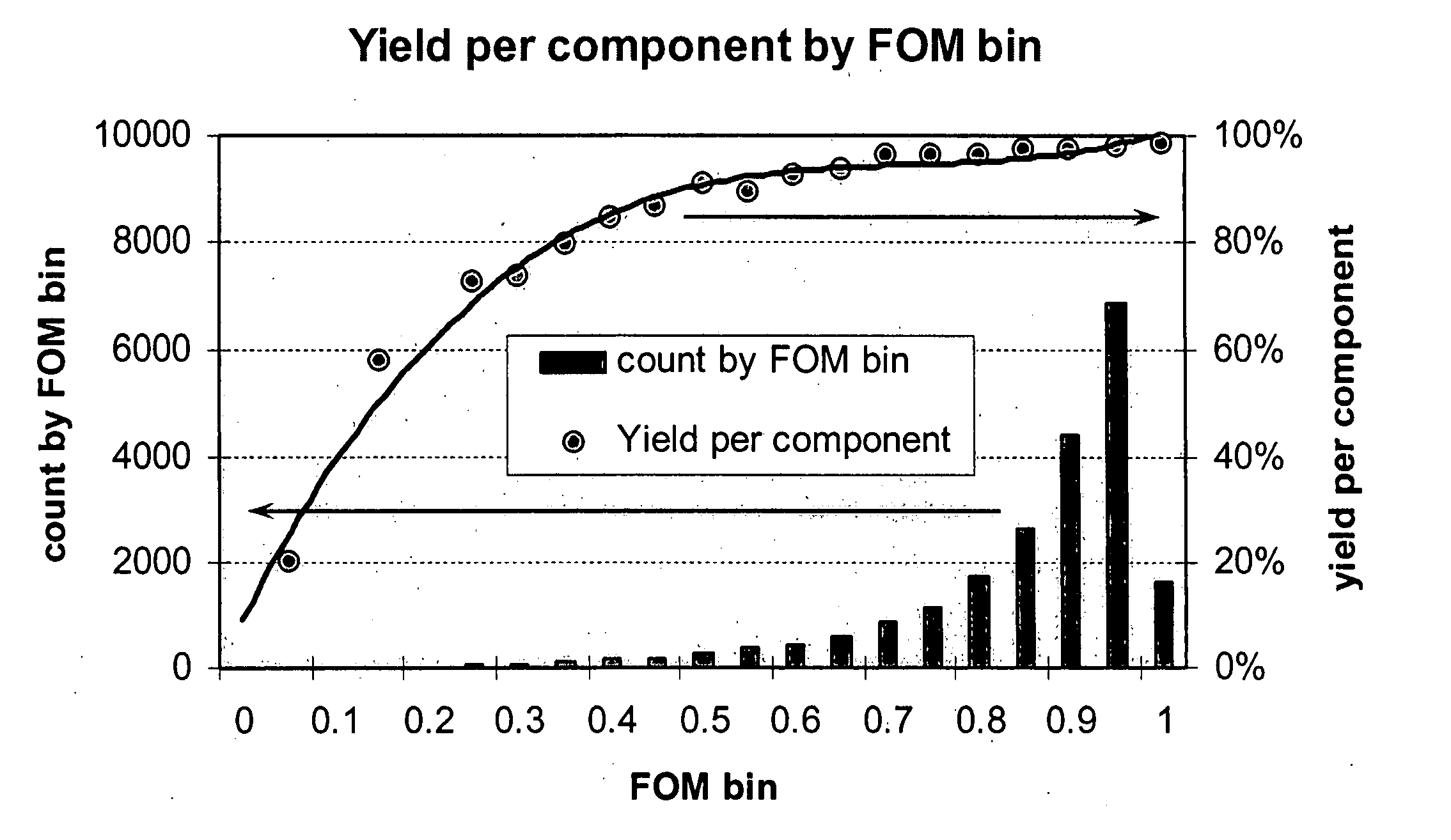

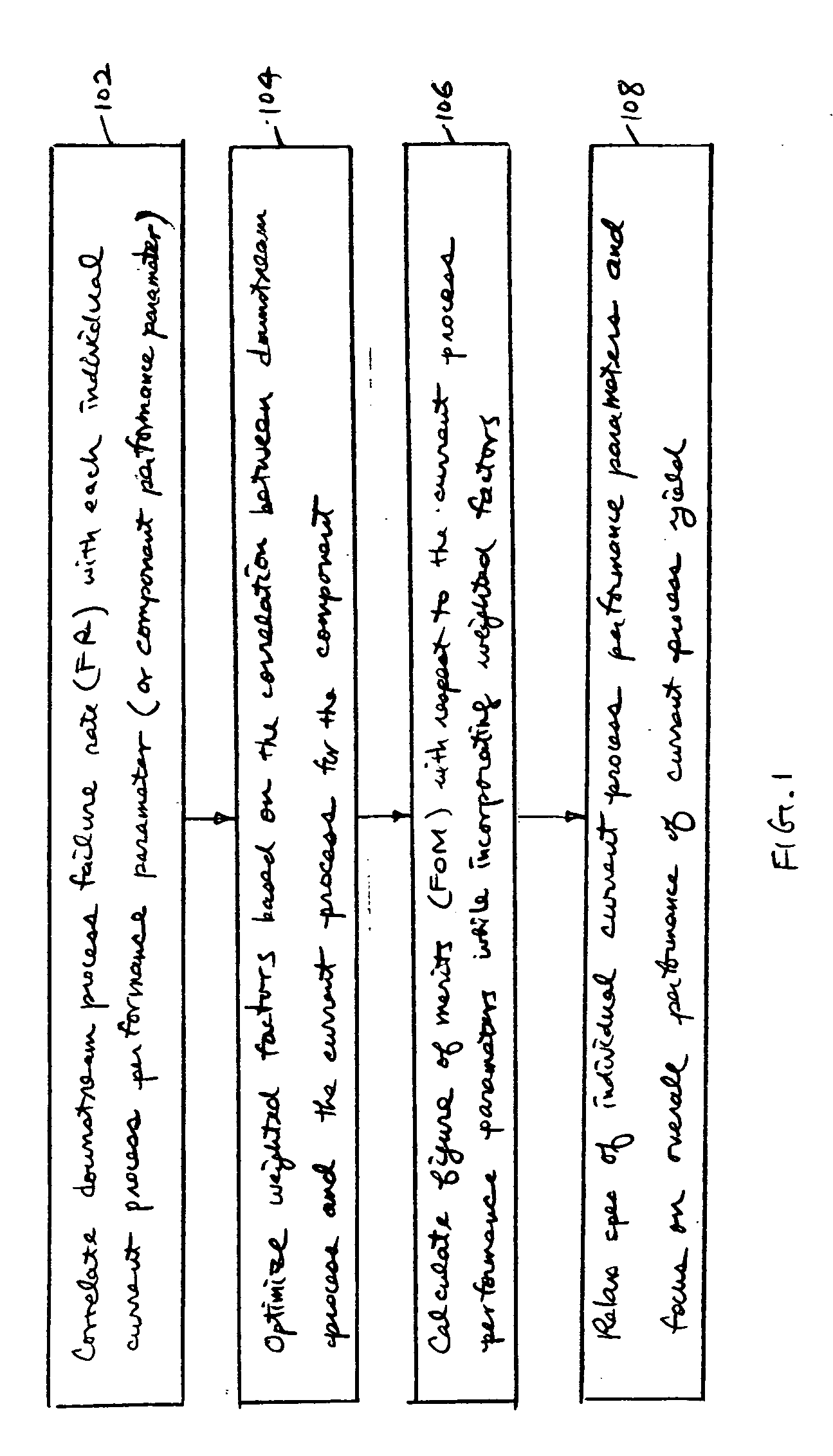

[0023]FIG. 1 shows a flow diagram of a method of enhancing the manufacturing yield of a downstream product with respect to a current manufacturing process of a component according to an embodiment of the invention. For the current manufacturing process of the component, a number of performance parameters will affect the component yield. In the example of the HDD manufacturing process flow, the current manufacturing process may be for the HGA component and the downstream process may be for the HDD product. The initial parameter selection for the HGA manufacturing process may be based on DET methodology (for example, HDD / DET correlation and mechanism of device operation) and tester control (for example, repeatability). Statistical software tools can further fine-tune the parameter selection.

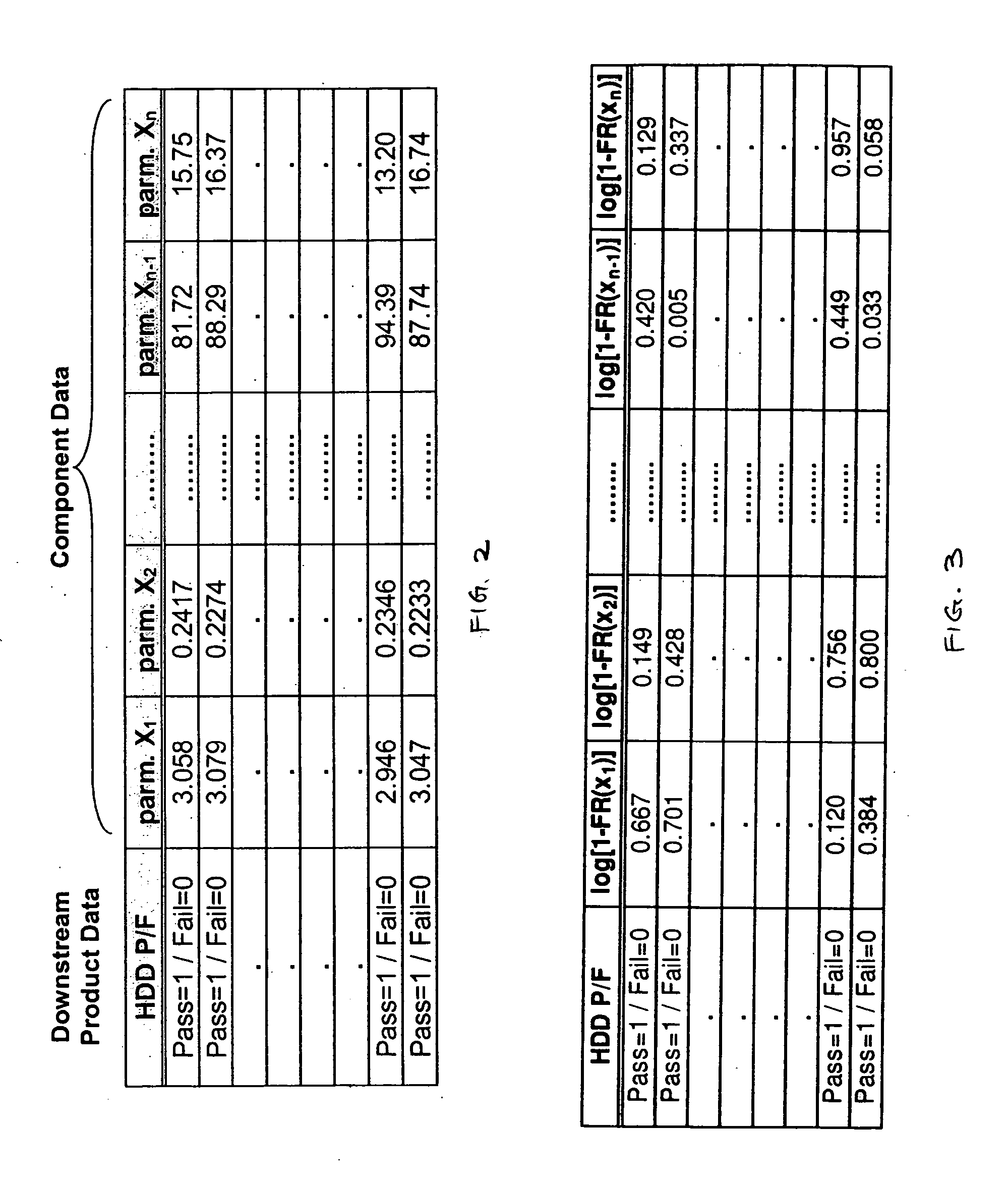

[0024] In step 102, the downstream product failure rate FR(xi) is correlated with each individual current process performance parameter (or component performance parameter). The yield is equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com