Application of heat to a screen or mesh covering a gutter, specifically to melt snow or ice

a technology for gutters and heat, applied in roofs, buildings, buildings, etc., can solve problems such as affecting the appearance of the roof, and affecting the appearance of the roof or guttering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

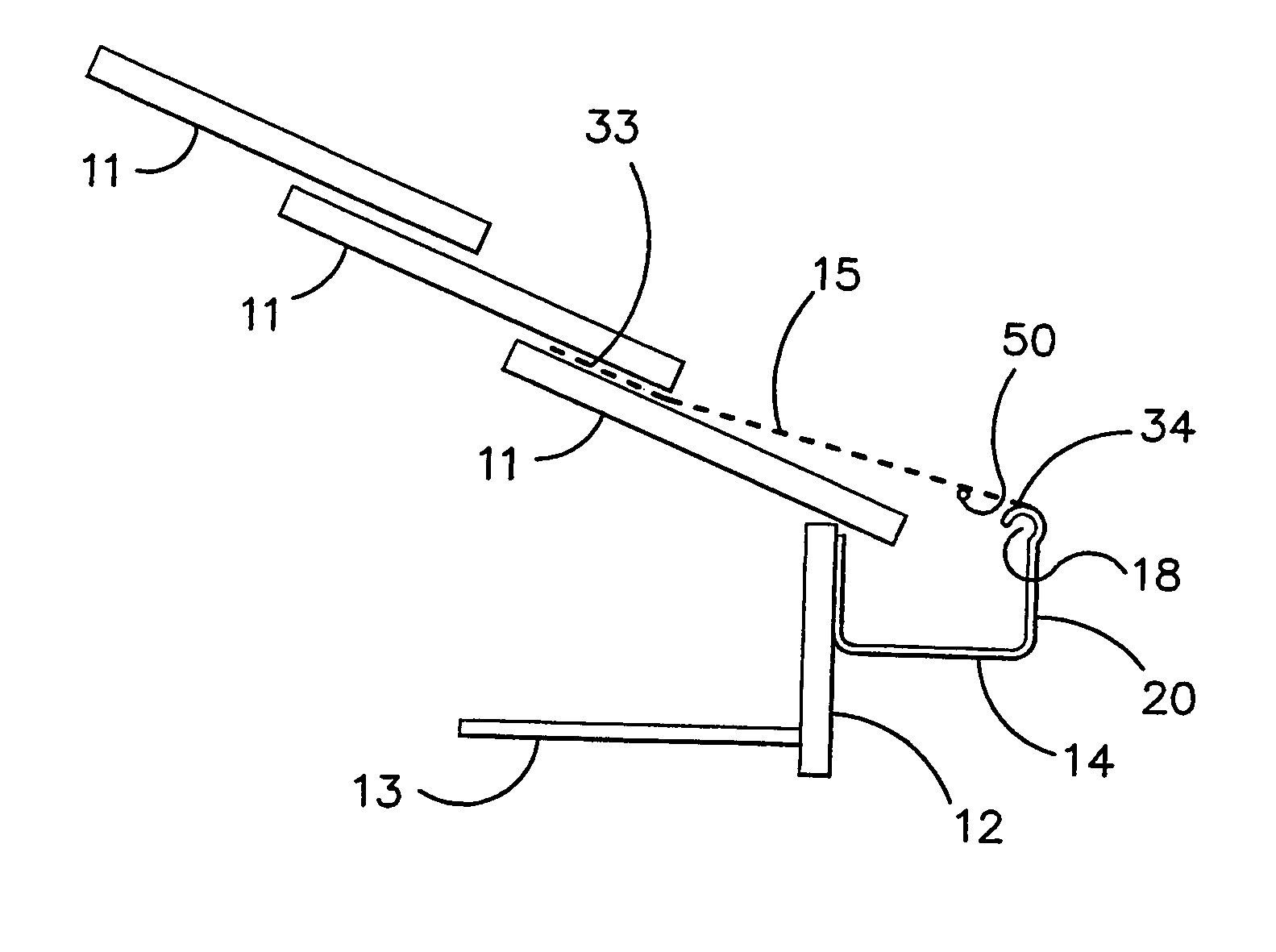

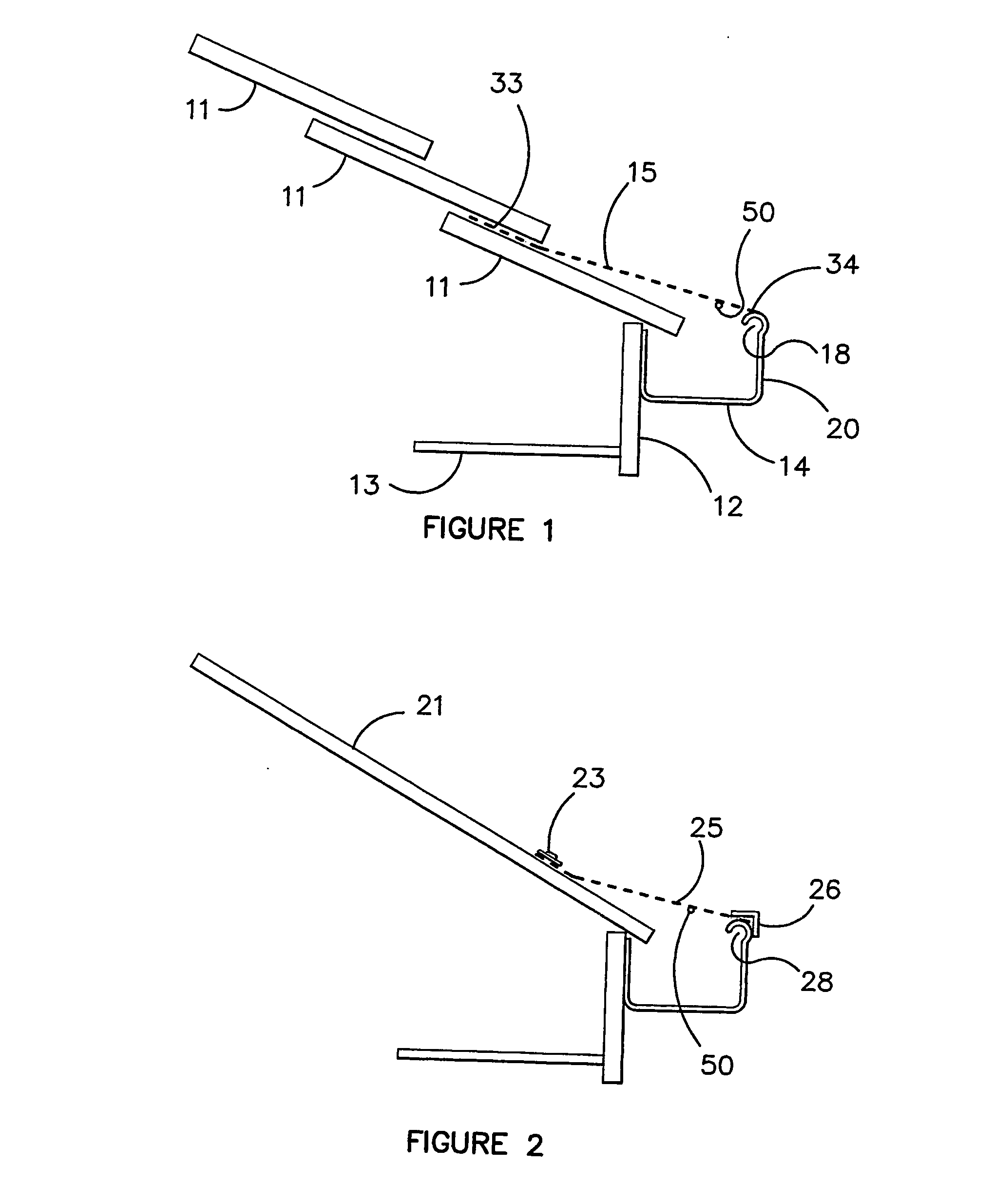

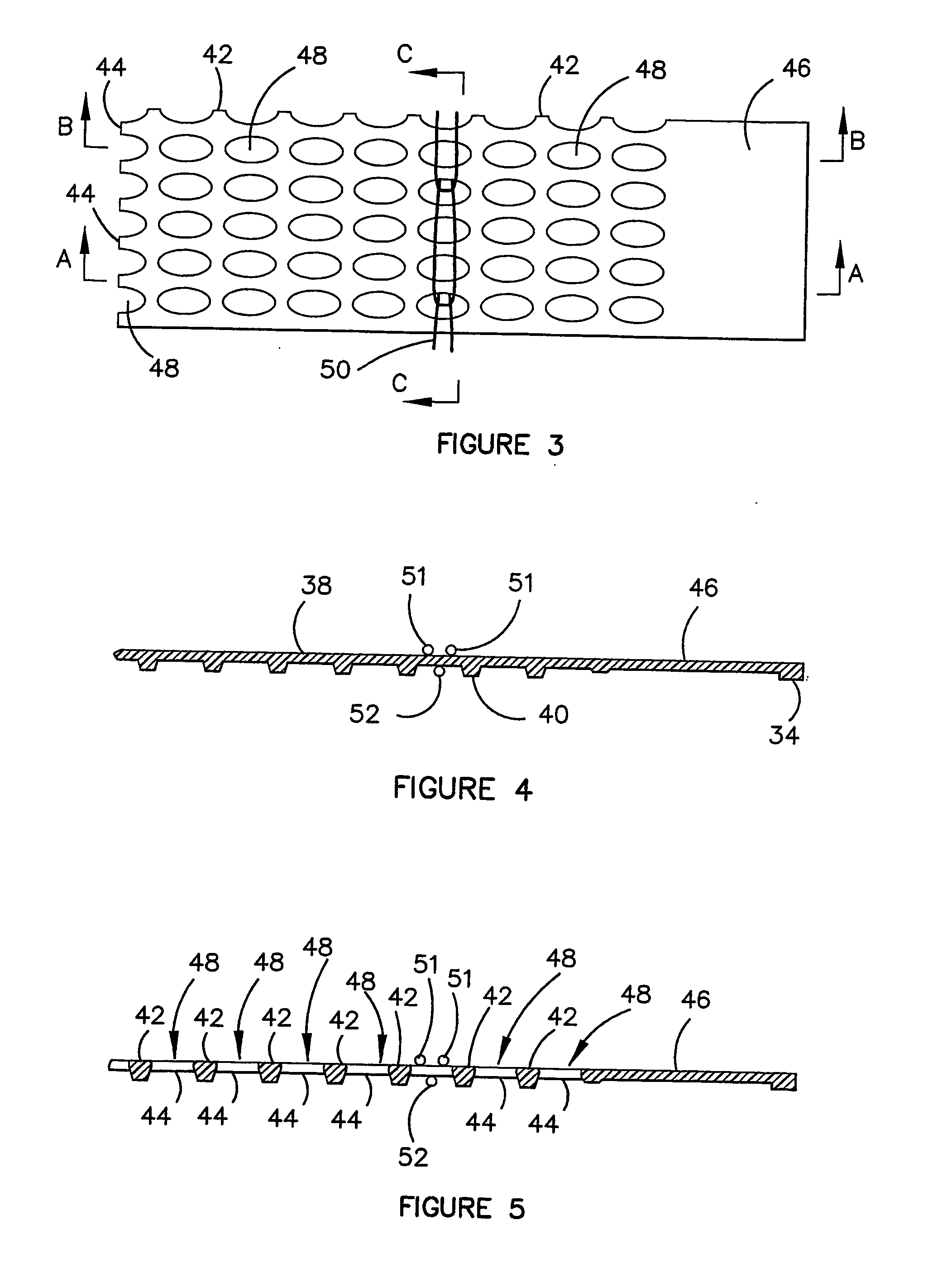

[0040] Referring to the installation shown in FIG. 1, the edge of a roof has roofing tiles 11, fascia 12, soffit 13 and gutter (also called guttering) 14. A panel 15 of mesh is fixed over the gutter 14 to prevent the entry of unwanted materials while allowing the free flow of water through the mesh and into the gutter 14. The panel 15 is formed by unrolling a roll of mesh along the length of the guttering 14 and attaching one edge 33 of the mesh to the roof and the other edge 34 to the guttering. The panel 15 is attached to the roof by the weight of the second bottom row of tiles 11 and to the guttering by means described later in this specification. A rounded lip 18 forms the top outside edge of the guttering 14 and lies at the top of the guttering's outer face 20. The mesh is flexible enough for the panel to easily bend to the profile of the roofing tiles 11 so that the tiles continue to be located by correct engagement with neighbouring tiles. A similar configuration of installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com