In-line fluid treatment device and system

a fluid treatment device and fluid treatment technology, applied in mechanical equipment, dissolving, transportation and packaging, etc., to achieve the effect of promoting efficient fluid treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

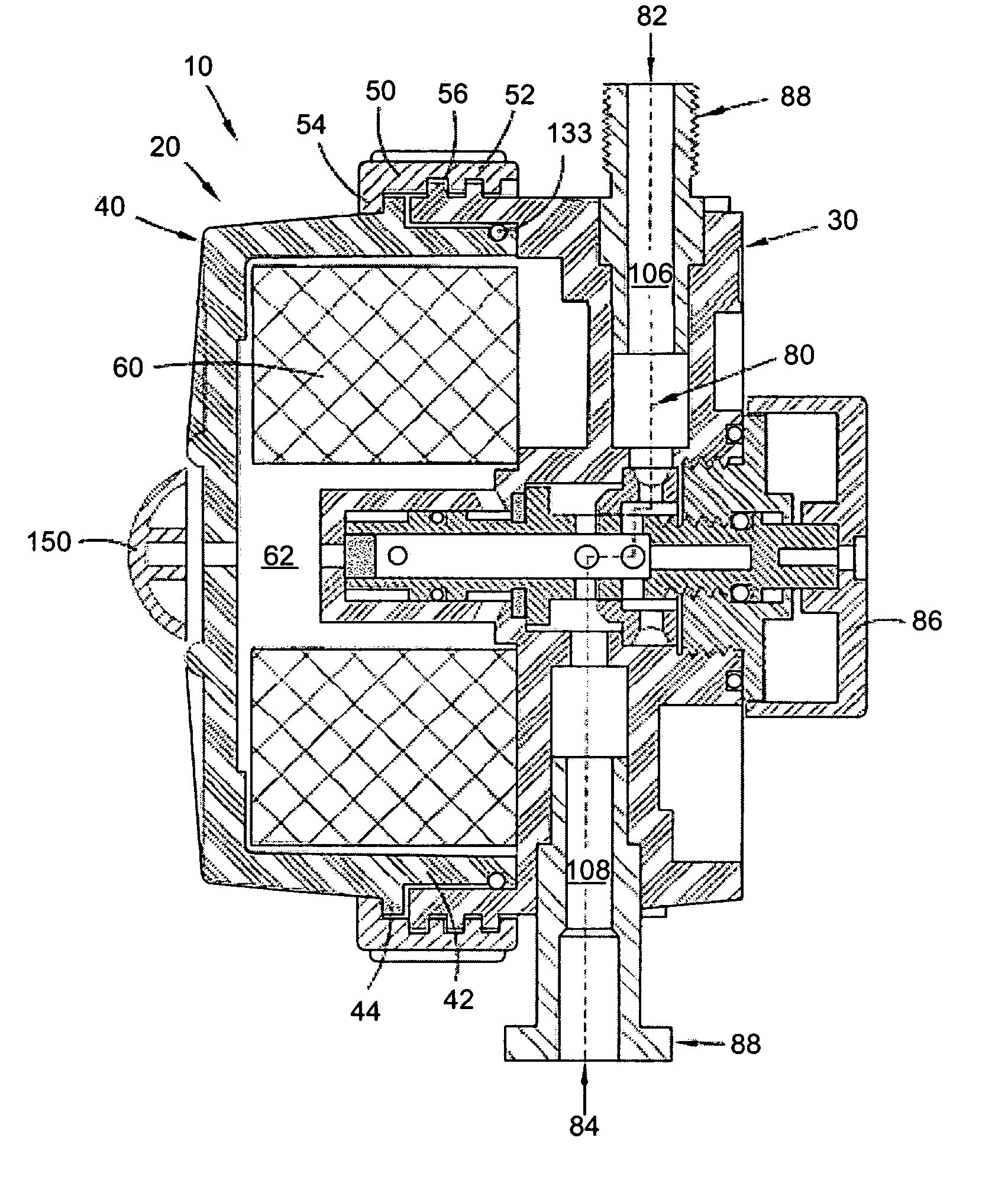

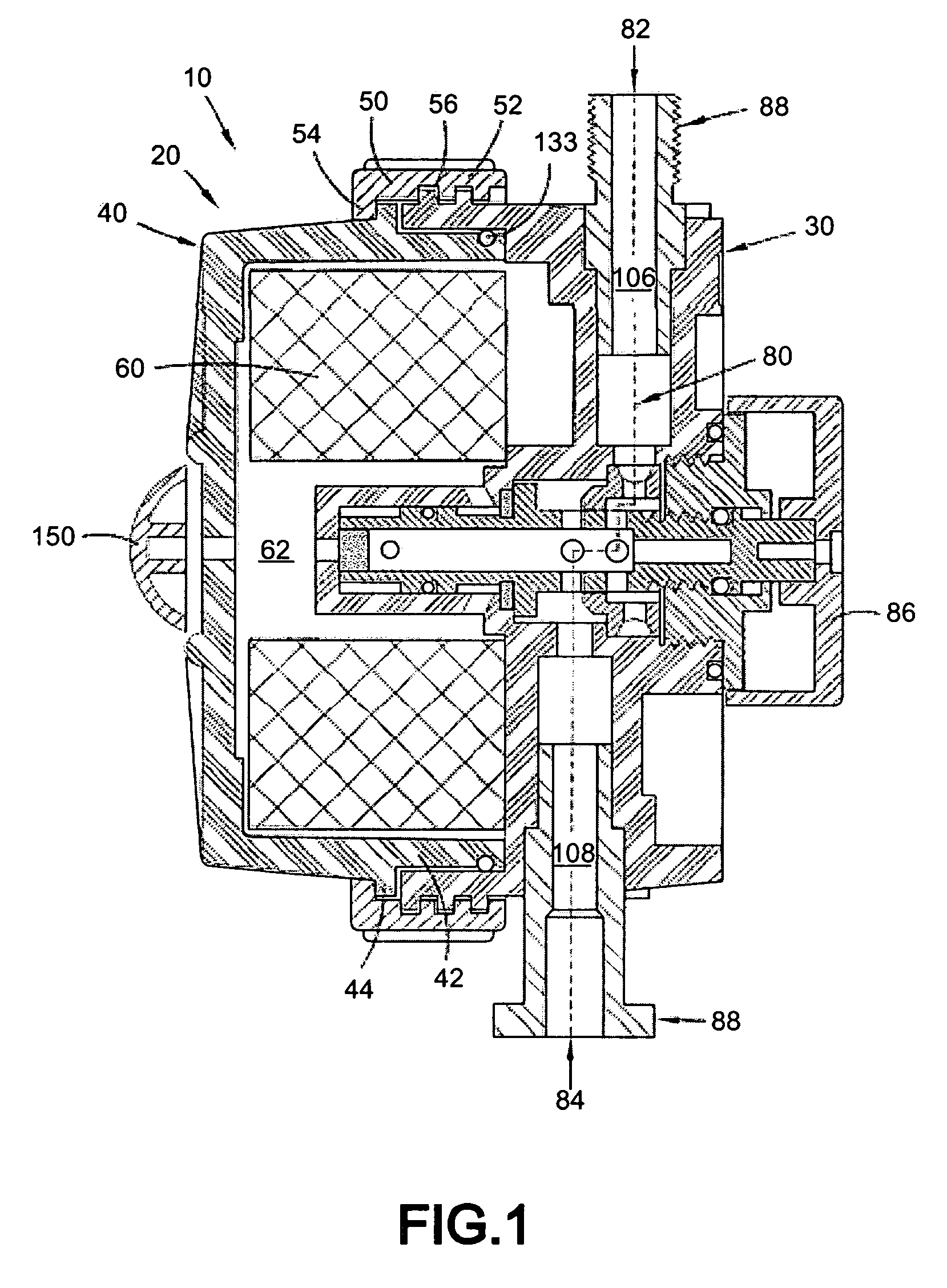

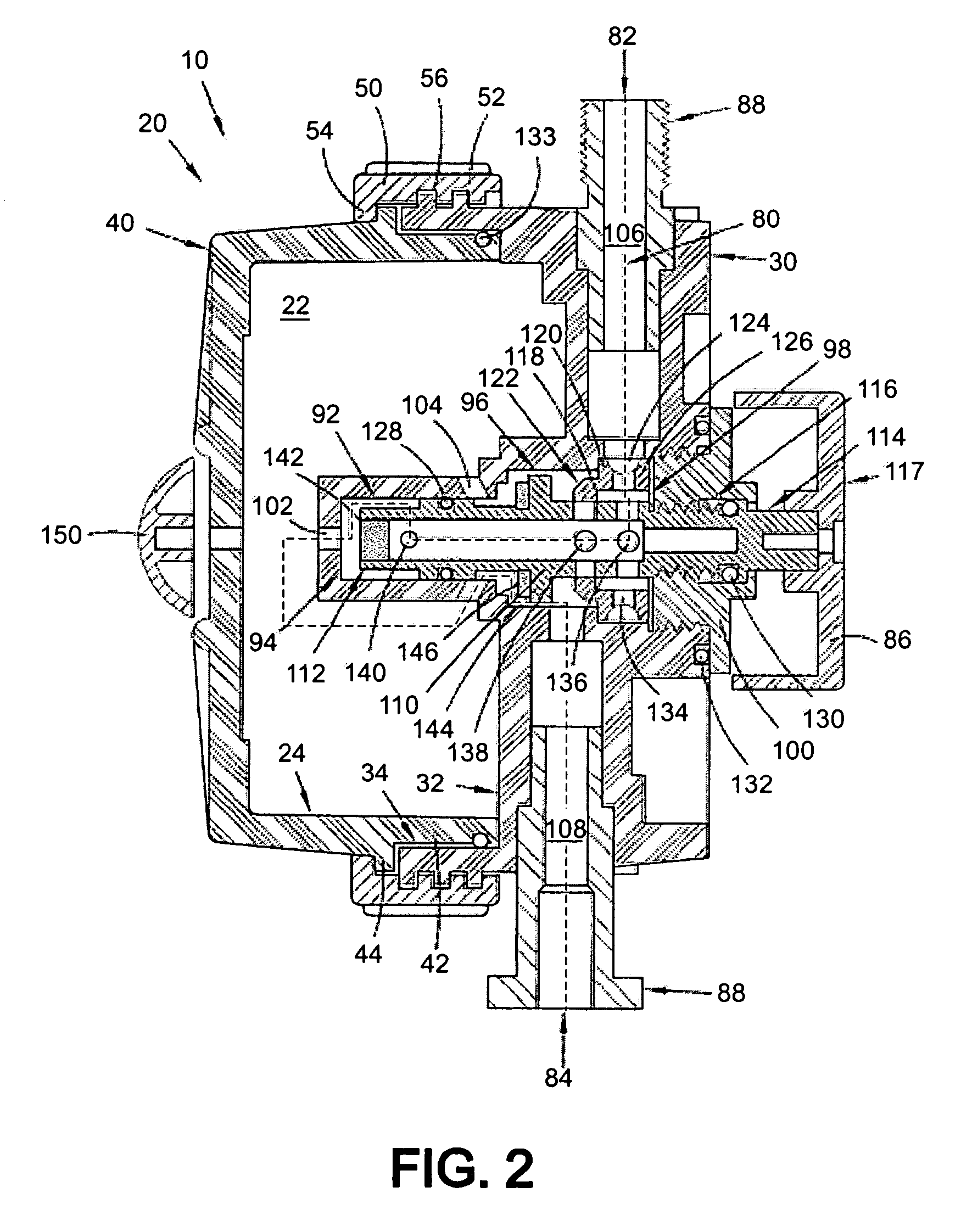

Image

Examples

Embodiment Construction

[0021] The material added into the housing to provide the chemistry for the operation of the system can comprise any chemistry to perform whatever specific tasks are desired to be provided. At a minimum, the material (which will be referred to herein as the “pellet,” although it may be in any form such as a bar, powder, gel, slug, sticks, or the like) should provide at least one of color (to mask dirt or waste), biocide (to kill virus or bacteria), fragrance or deodorizer, water softening agent (to reduce deposits), chelating agents (to prevent metal or metal oxide deposition, surfactant (for cleaning functions), and the like. Other ingredients may be present such as binding agents, dispersing agents, dispersant accelerants, thickening agents, foaming agents, anti-foaming agents, and the like, without limit for useful functions in the environment of this technology.

[0022] A non-limiting example of a specific compacted pellet according to the practices envisioned in this field is:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com