High Carbon steel wire material having excellent wire drawability and manufacturing process thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

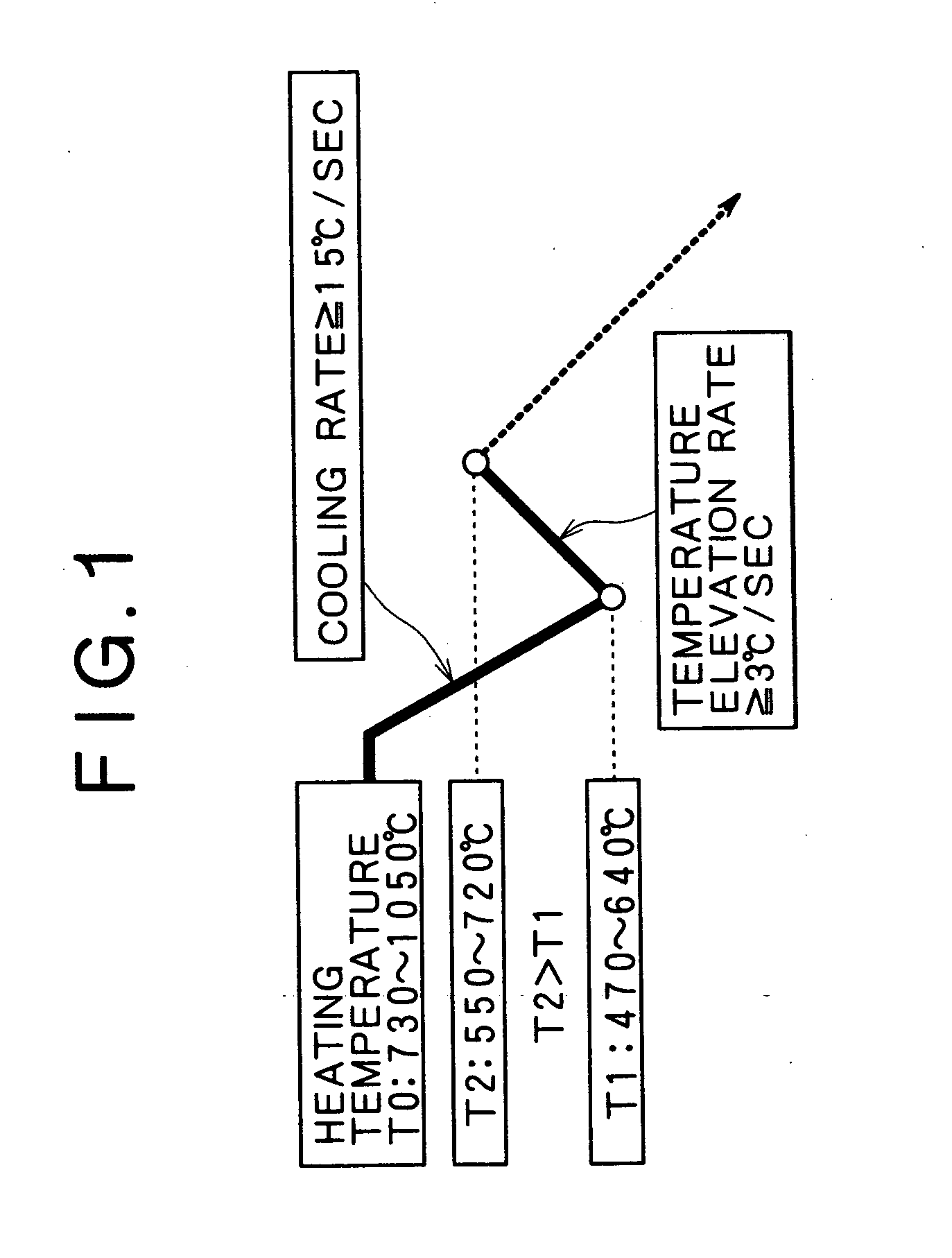

[0071] A hot rolled steel wire material having a diameter of 5.5 mm having chemical composition shown in Table 1 was manufactured. The amount of REM in Table 1 shows the total amount of La, Ce, Pr and Nd. The obtained hot rolled steel wire material was heated in an atmospheric furnace under conditions shown in FIG. 1 and Tables 2 and 3 and charged continuously into a lead furnace to be heated so as to obtain various steel wire materials. In this experimental example, the atmospheric furnace and the lead furnace were used to carry out the above heat treatment. The present invention is not limited to the use of these devices and other heating furnaces and holding furnaces may be used as a matter of course.

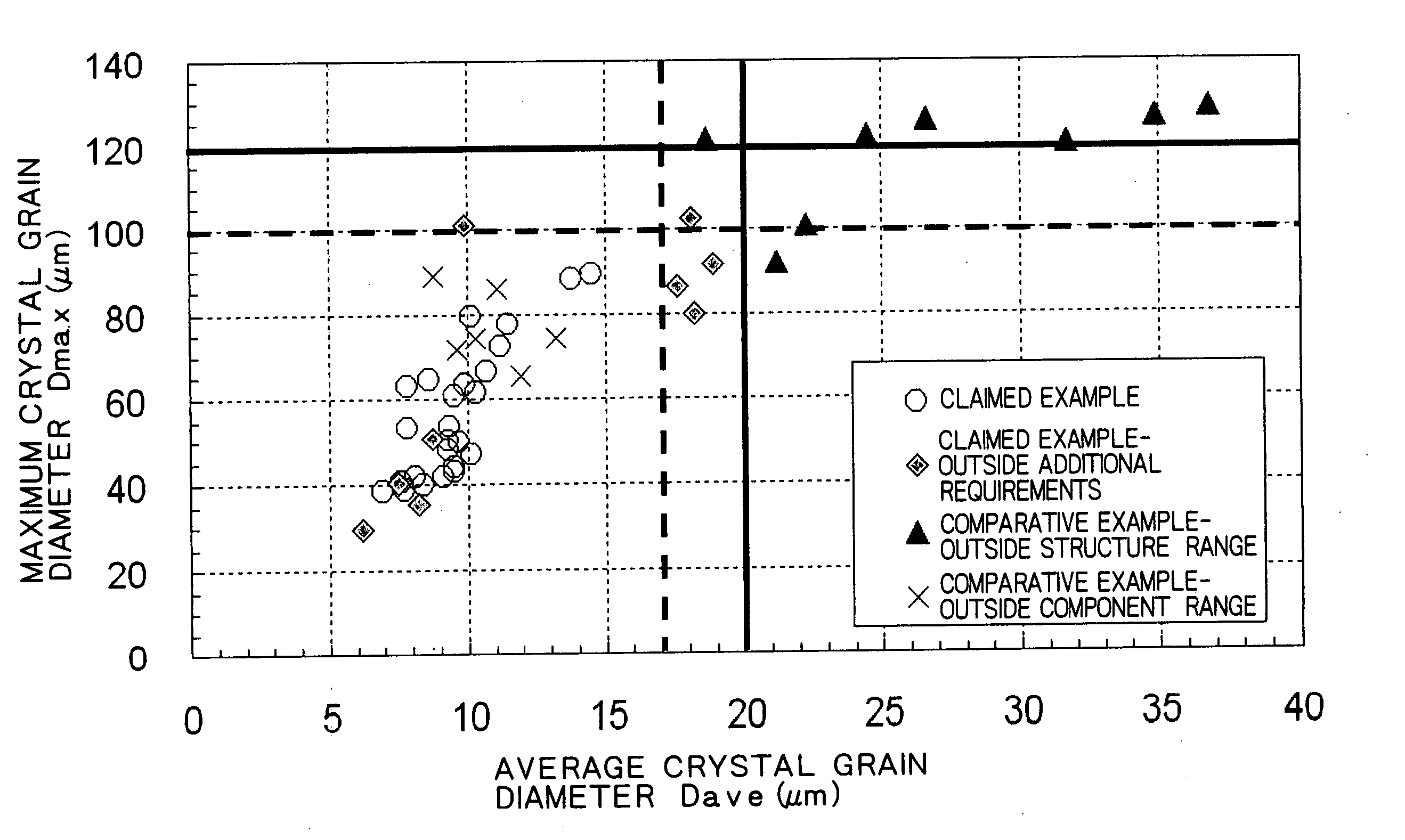

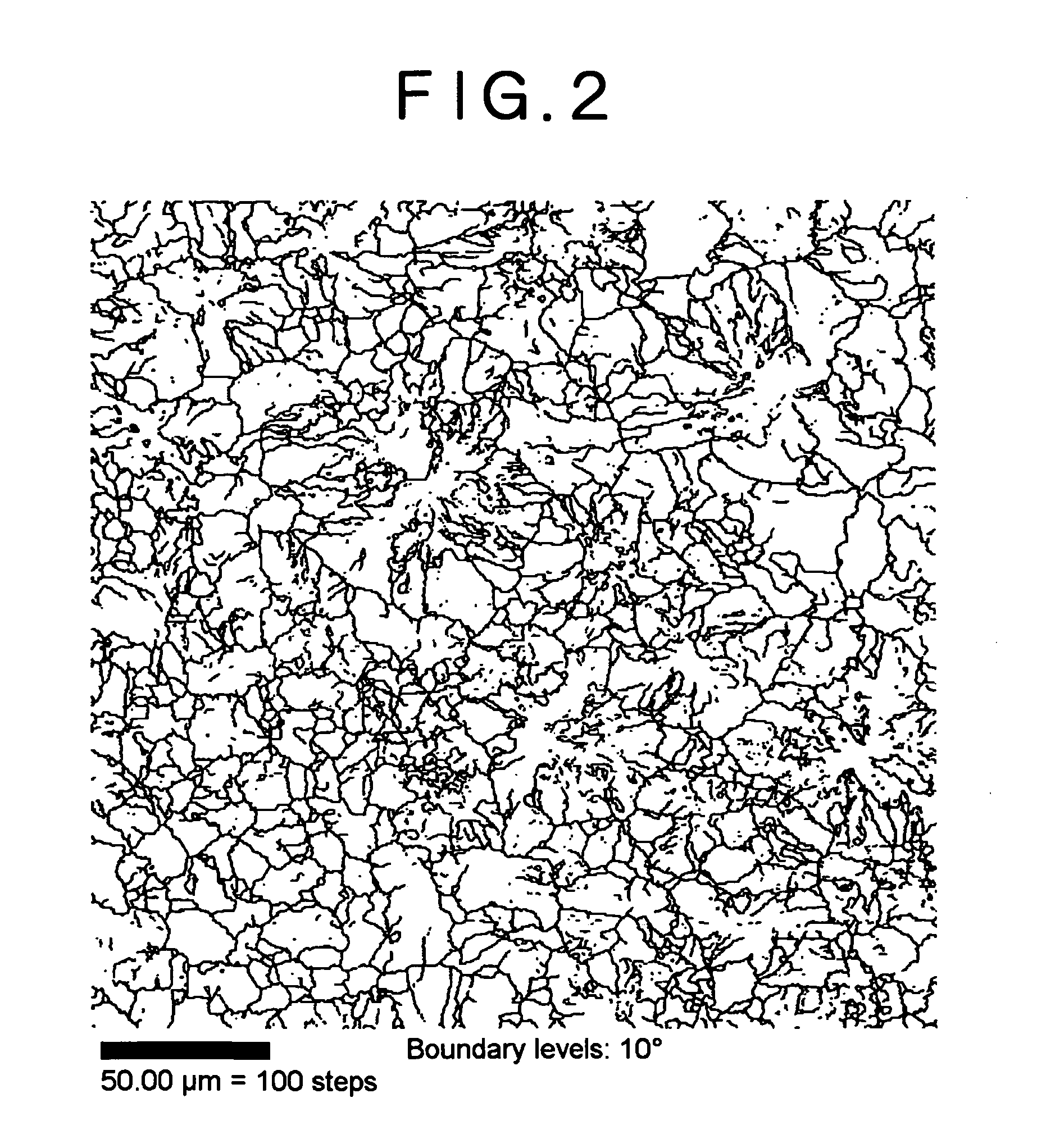

[0072] The structural features, scale characteristics and tensile characteristics of the obtained steel wire materials were evaluated. As for the crystal units of bcc crystal grains and sub grains out of the structural features, as the evaluation of variations in each crystal unit i...

experimental example 2

[0093] To improve wire drawability as hot rolled, types of steel shown in Table 5 below were used and studied. The amount of REM in Table 5 shows the total amount of La, Ce, Pr and Nd. All the types of steel shown in Table 5 satisfy the requirements for composition specified by the present invention.

[0094] The types of steel shown in Table 5 were hot rolled under conditions shown in Table 6 and FIG. 5. In the case of a hot rolled material, all the steps from a heating furnace to rolling and cooling must be controlled. As shown in FIG. 5, the control items are more complicated than in the above Experimental Example 1 (FIG. 1). The structural features, scale characteristics, tensile characteristics and wire drawability of the obtained hot rolled materials were evaluated in the same manner as in the above Experimental Example 1.

[0095] The results are shown in Tables 6 to 8 and FIG. 6. By suitably controlling a series of steps from heating to winding and cooling for hot rolling, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com