Decorative finial structure for curtain rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

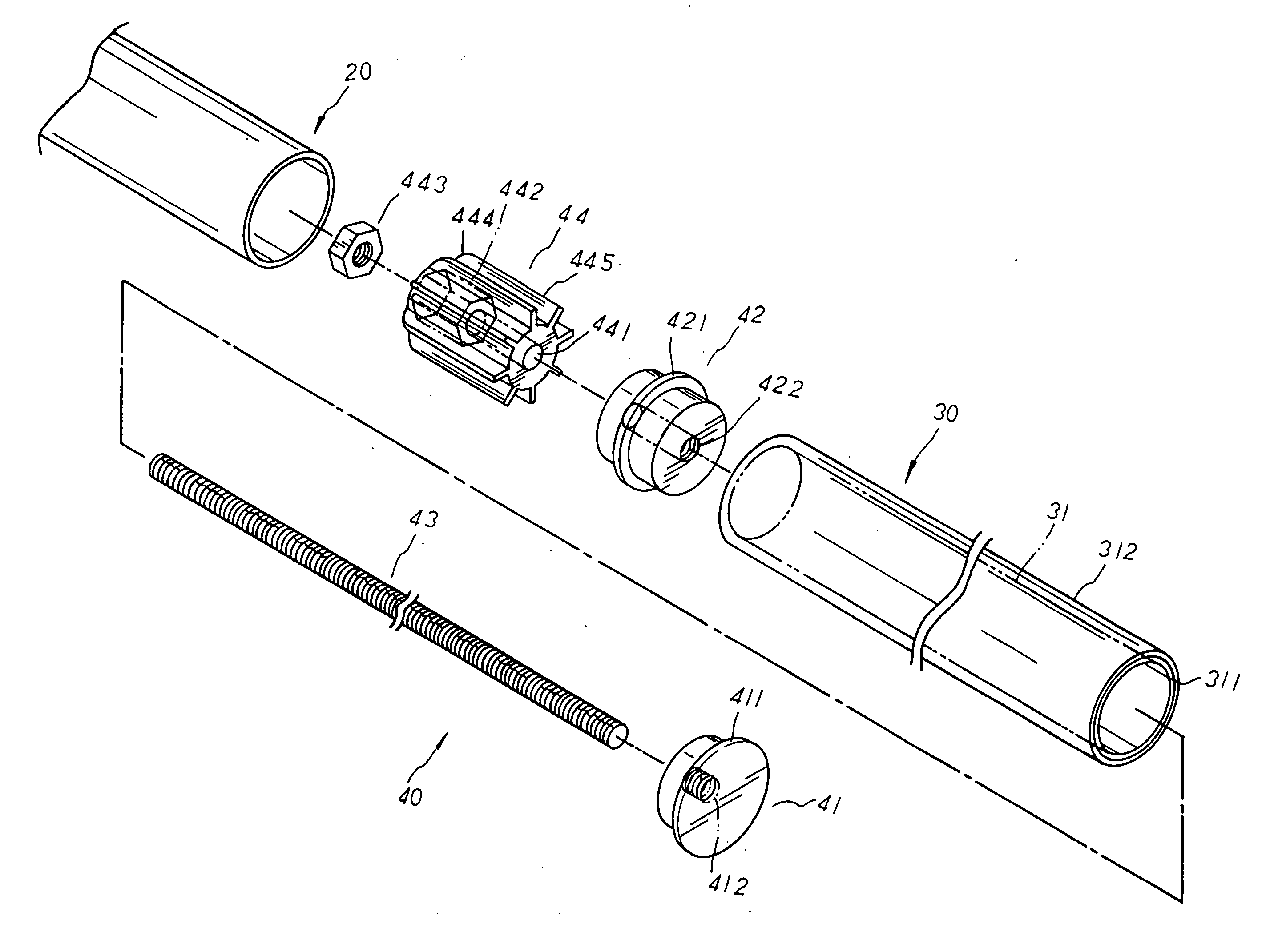

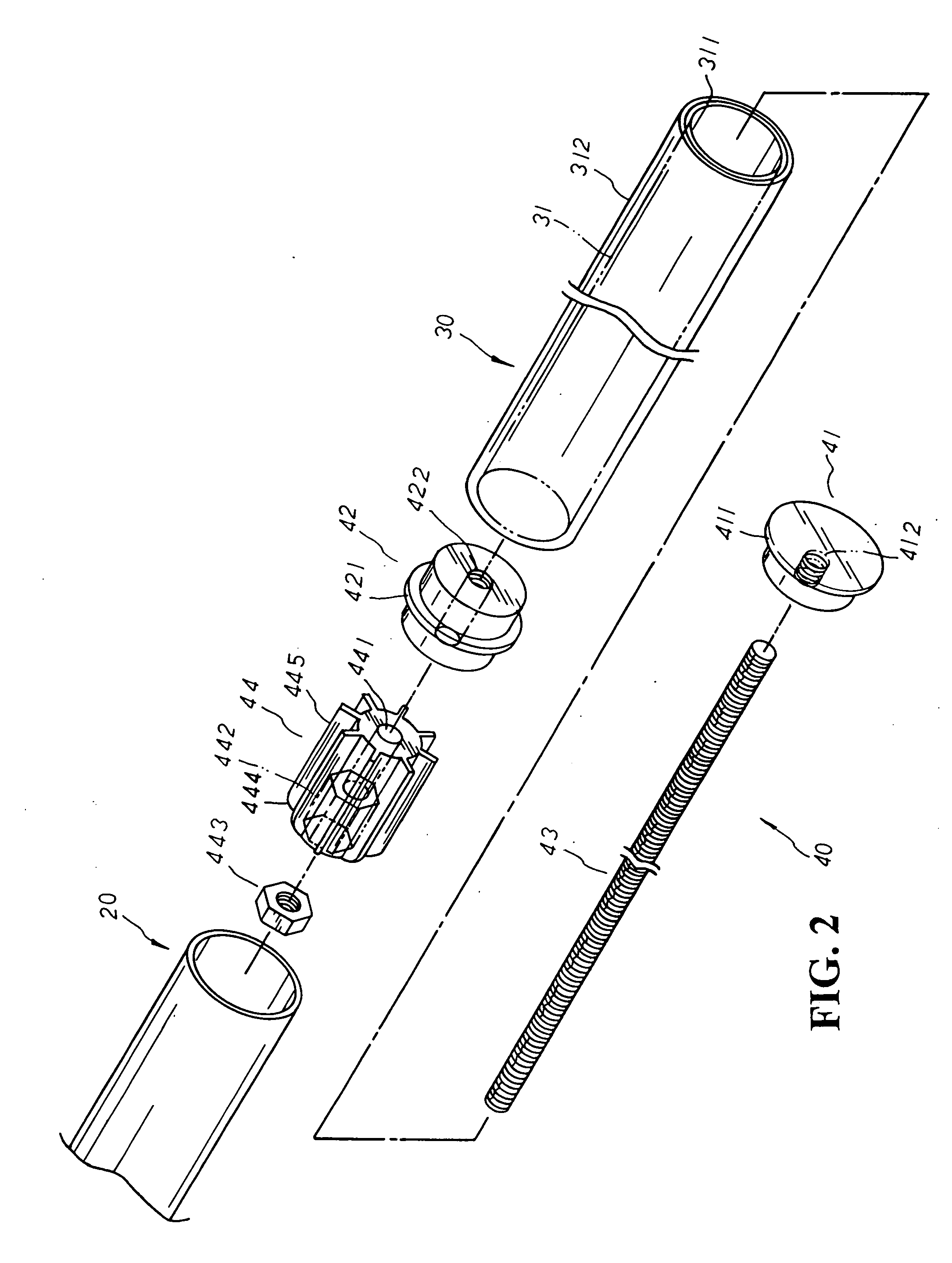

[0012] Please refer to FIG. 2 showing an exploded perspective view of the present invention. The present invention is related to a decorative finial structure for use of curtain rods, comprising a decorative unit 30 and an assembly unit 40 wherein the decorative unit 30 is made up of a hollow and tubular main body 31 with a stop flange 311 disposed at both ends thereof respectively, and a decorative layer 312 of leather and colored (like brown, or black) material that is wrapped and preferably fastened at the outer surface of the tubular main body 31 thereof The assembly unit 40 includes a sealing cap 41, a coupling sleeve 42, a fixing rod 43, and a retaining member 44 wherein the sealing cap 41 and the coupling sleeve 42 thereof are respectively matched to the inner diameter of the main body 31 for mutual engagement therewith. At one side of the sealing cap 41 and at the middle section of the coupling sleeve 42 are respectively disposed a stop ring 411 and a protrusive ring 421 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com