Sensor

a technology of sensors and connectors, applied in the field of sensors, can solve the problems of disconnection of the base end, broken base end of the lead, loose lead, etc., and achieve the effect of improving the bonding strength of each lead to the sensor element, reducing the electric resistance value in the connected portion, and improving the connection strength of the end portion of each lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

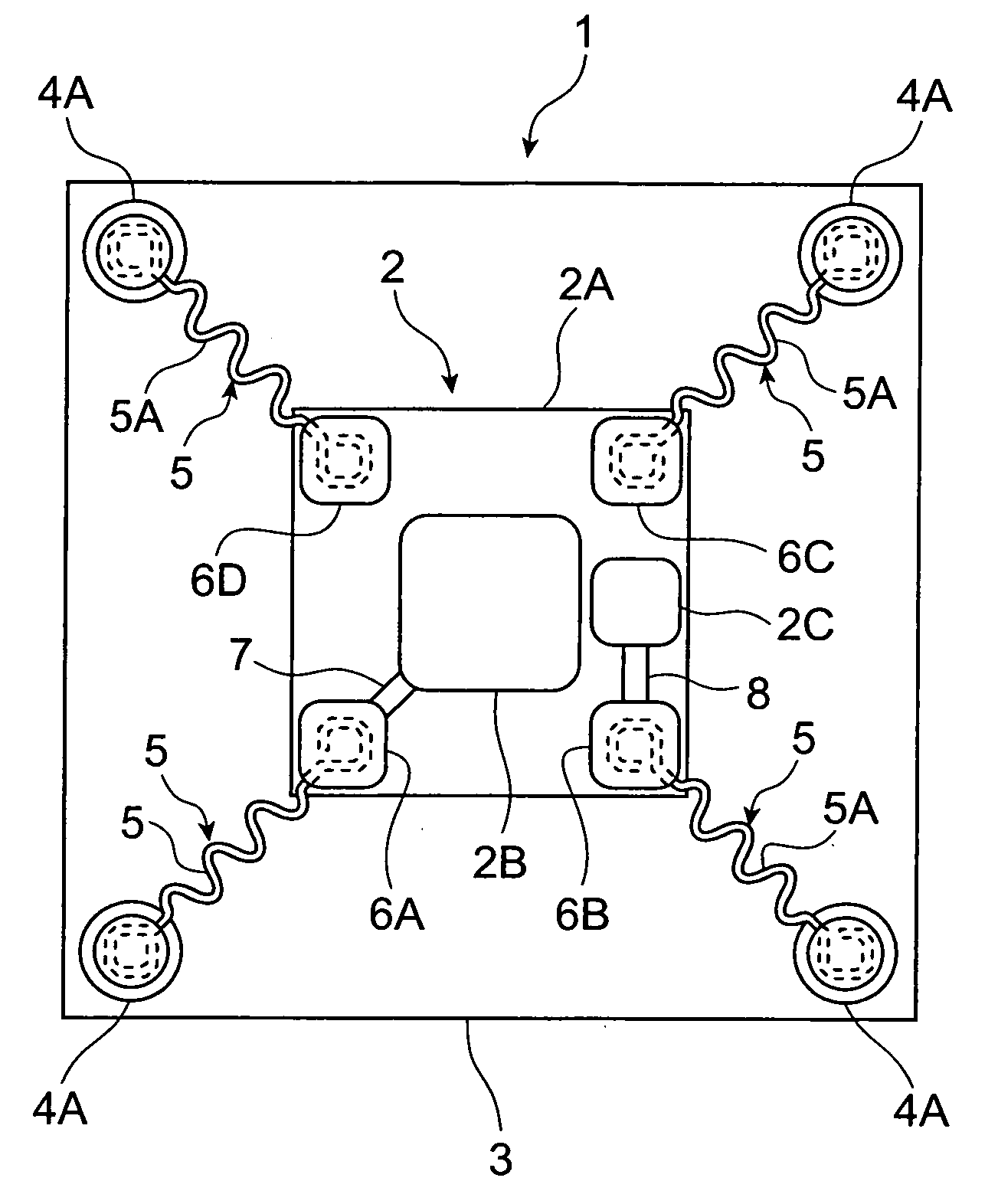

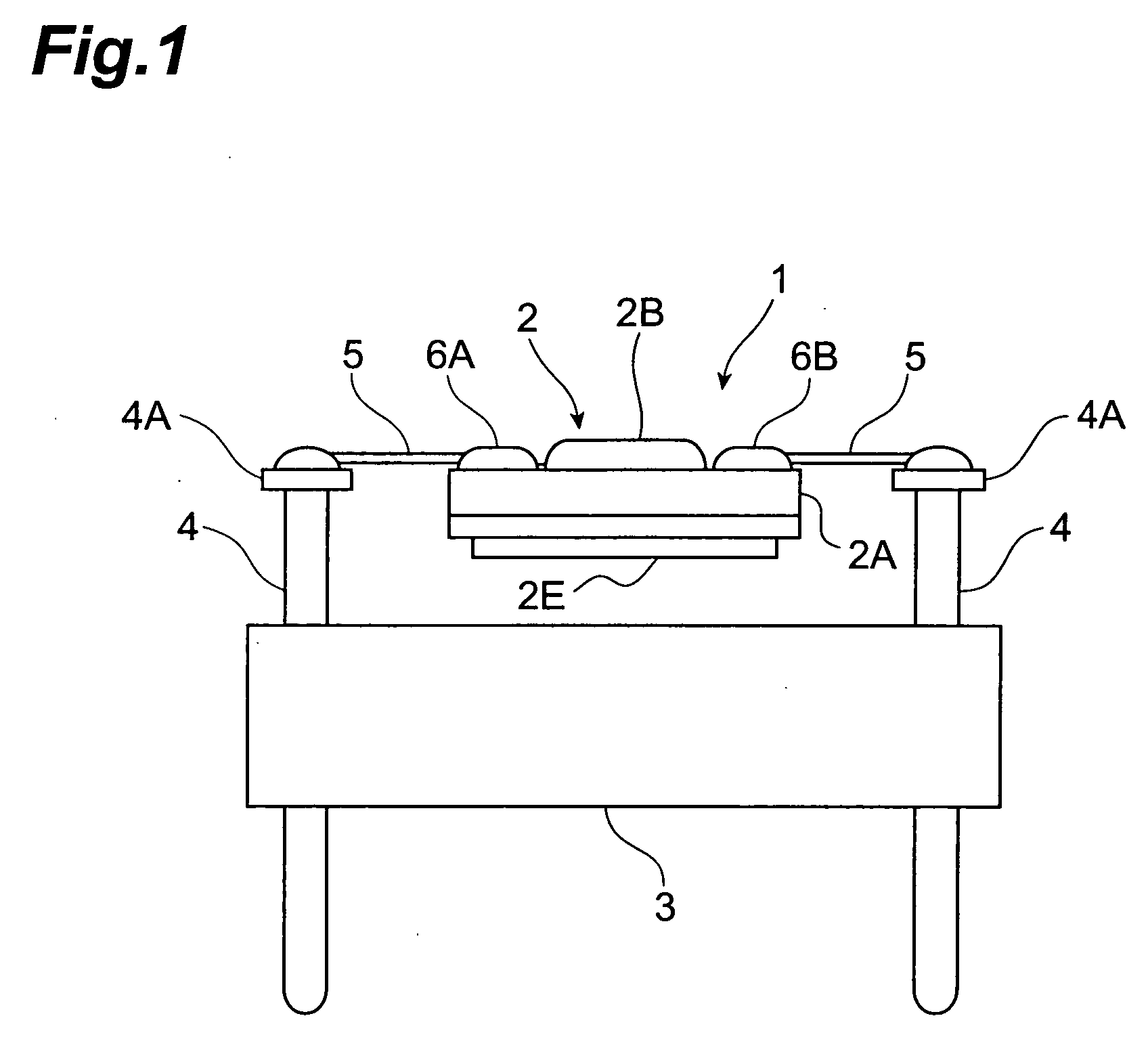

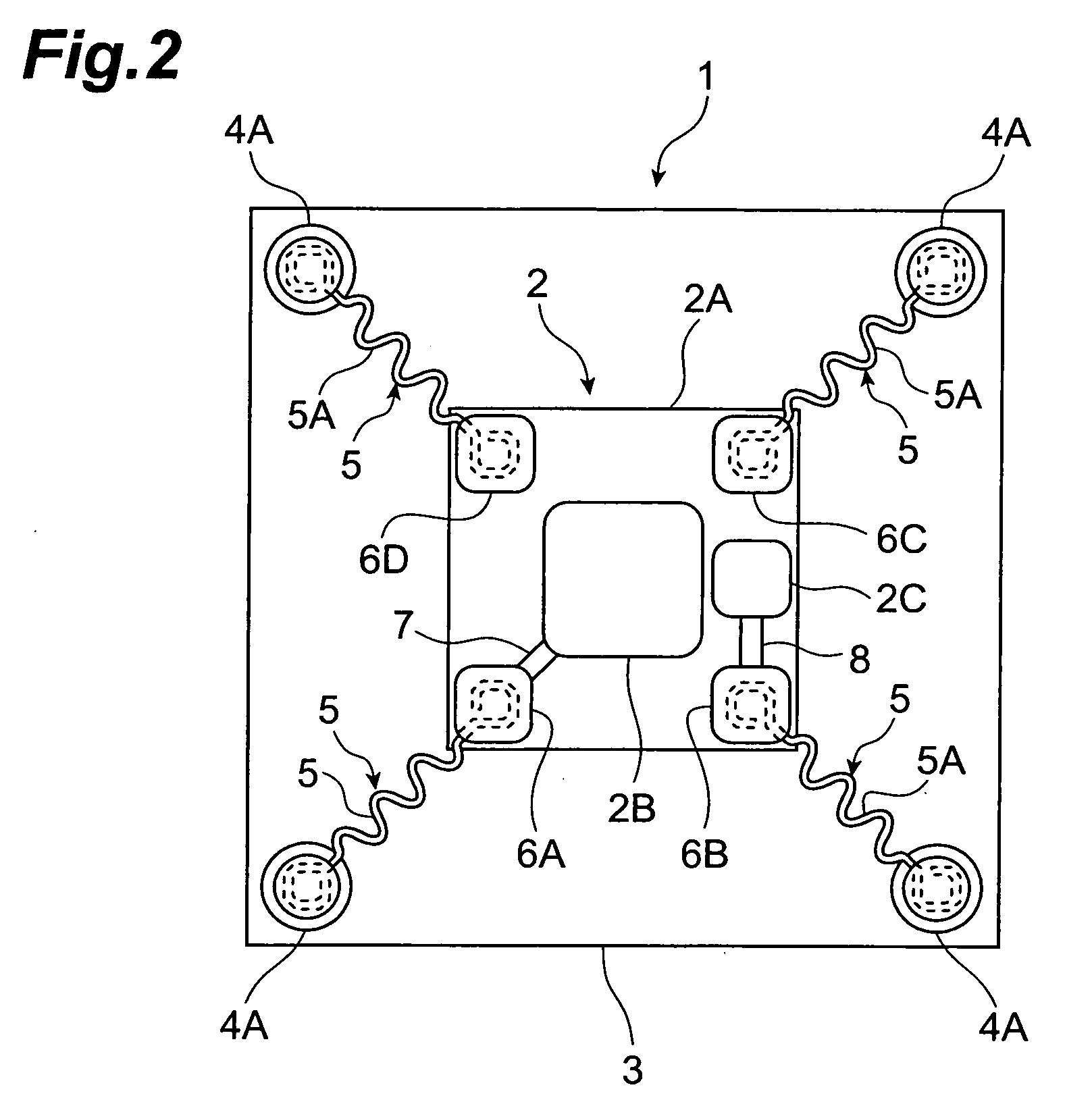

[0048] Hereinafter, embodiments in which the gas sensor, out of the sensors according to the present invention, is exemplified will be explained by making a reference to the accompanied drawings. In the figures to which a reference is made, FIG. 1 is a side-view illustrating a schematic structure of the gas sensor according to one embodiment, and FIG. 2 is a plan view of the gas sensor shown in FIG. 1.

[0049] A gas sensor 1 of one embodiment shown in FIG. 1 and FIG. 2 is a gas sensor for detecting the concentration of, for example, carbon dioxide (CO2) as a specific gas in the atmospheric gas. The gas sensor 1 comprises a gas sensor element 2 for detecting carbon dioxide (CO2). This gas sensor element 2 is connected to four stem pins 4 via four leads 5 respectively. The stem pins 4 are fastened in the vicinity of four comers of a base plate 3 in a penetration state. The gas sensor element 2 is supported in a suspension state by each of stem pins 4 via each of the leads 5.

[0050] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com