Process and apparatus for grinding work for non-circular rotor, as well as camshaft

a technology of non-circular rotors and grinding machines, which is applied in the direction of edge grinding machines, grinding machine components, manufacturing tools, etc., can solve the problems of reduced indexing accuracy, difficult shortening of grinding time, and reduced standard phase indexing accuracy, so as to achieve good camshaft appearance and simplify the manufacture of blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

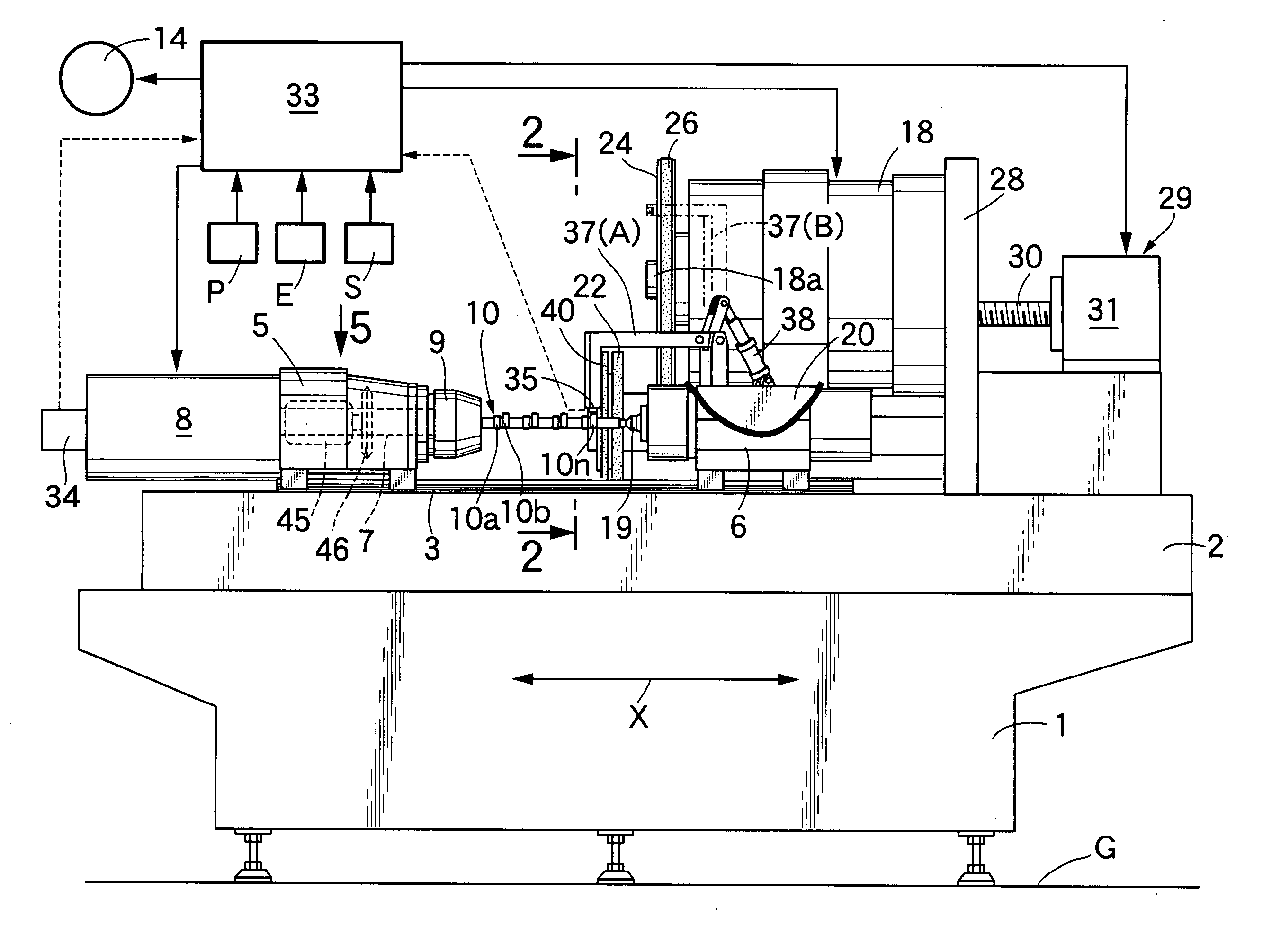

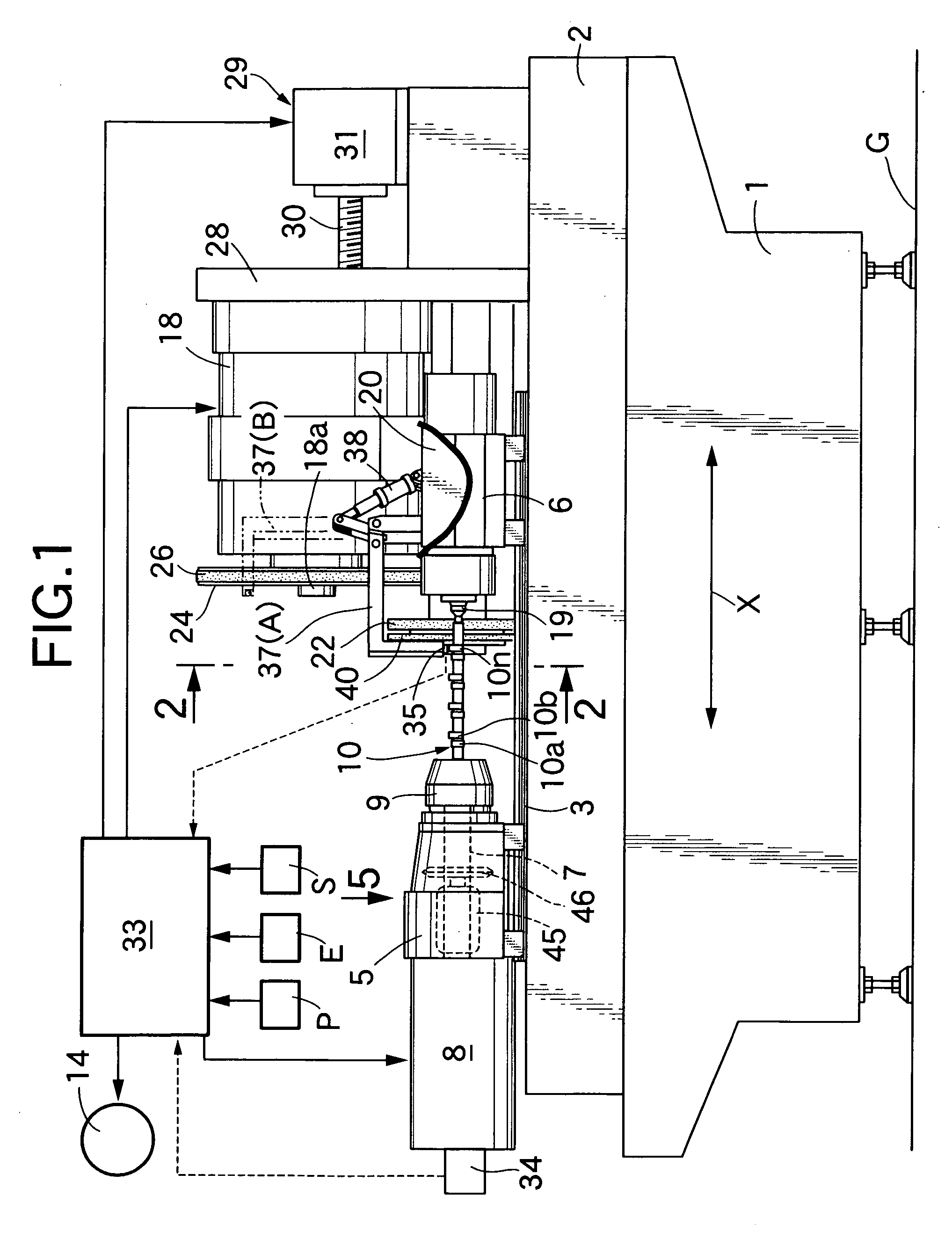

first embodiment

[0040] The operation of the first embodiment will be described below.

[0041] First, to carry out the dressing of the rotary grindstone 22, the outer peripheral surface of the rotary grindstone 22 rotated along with the wheel spindle 21 is brought into contact with the diamond dresser 46 and fed axially, while rotating the wheel spindle 21 at a low speed by the operation of the third electric motor 18 in a state in which the diamond dresser 46 is being rotated at a high speed by the operation of the dressing motor 45, as shown in FIG. 5.

[0042] During such dressing of the rotary grindstone 22, the rotational speed of the wheel spindle 21 is relatively low and hence, each of the wires 42 of the deflashing brush 40 is in contracted state and thus, the diameter of the deflashing brush 40 is smaller than that of the rotary grindstone 22. Therefore, it is possible to avoid the interference of the deflashing brush 40 with the diamond dresser 46.

[0043] Now, to grind the outer peripheral sur...

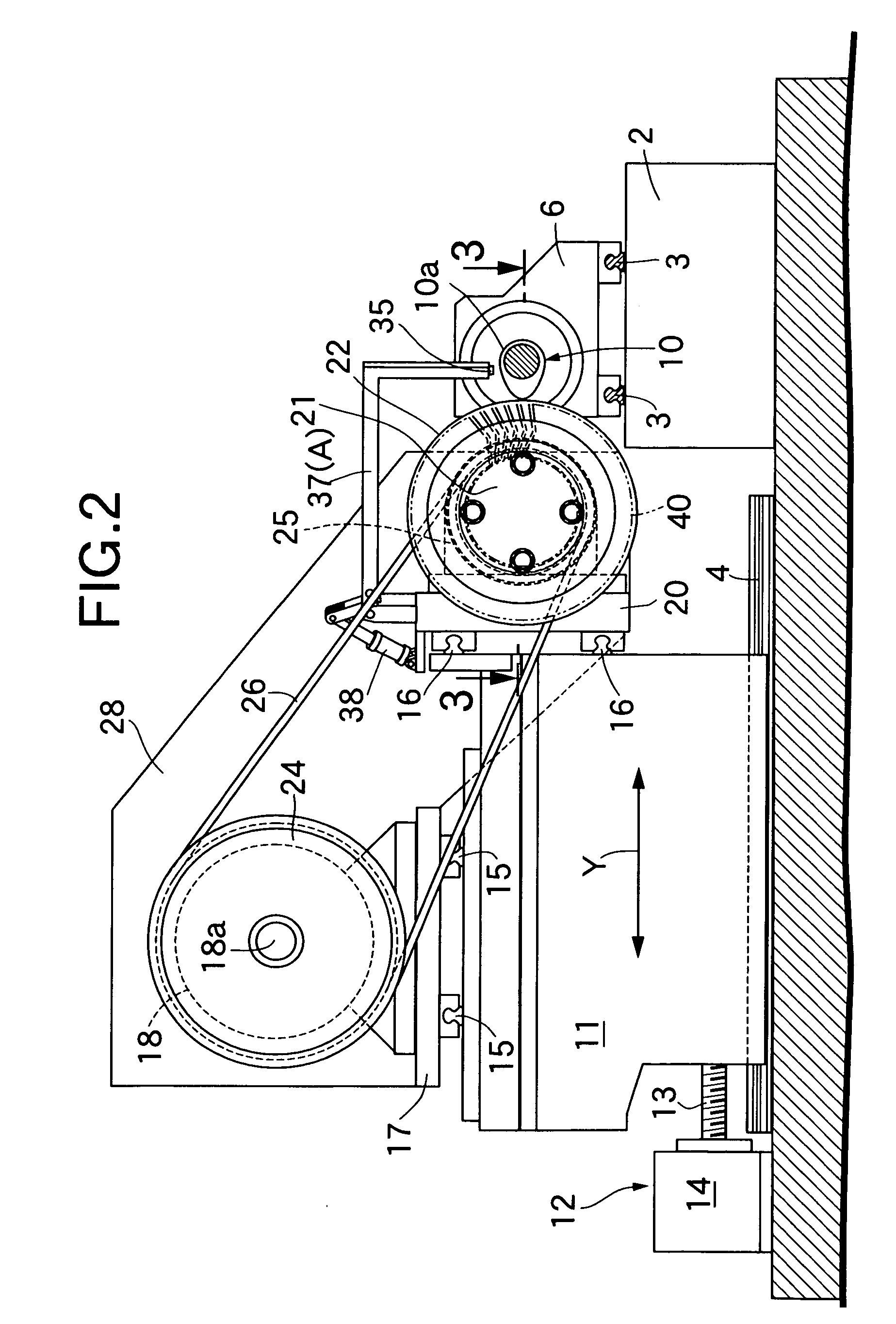

second embodiment

[0051] the present invention shown in FIG. 8 will now be described.

[0052] The second embodiment is different from the previous embodiment in respect of the construction of a deflashing brush 40. More specifically, through-bores 44, 44 are made in a brush body 41 and arranged circumferentially in a large number of sets with the adjacent two thereof disposed in a V-shape on opposite sides of a radius line R to form a pair. Two tip ends of a wire 42 bent into a V-shape at its central portion are inserted through each of the pairs of the through-bores 44, 44 from the side of an inner periphery of the brush body 41, and the wire 42 is brazed in each of the through-bores 44. The wire 42 bent into the V-shape is inclined with respect to the radius line R of the brush body 41 in its free state, so that its tip end is located radially inside the outer peripheral surface of the rotary grindstone 22, as shown by a solid line in FIG. 8. However, when the wheel spindle 21 is brought into a prede...

PUM

| Property | Measurement | Unit |

|---|---|---|

| constant curvature radius | aaaaa | aaaaa |

| distances | aaaaa | aaaaa |

| axial distances | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com