Combination structure of a quick assembly do-it-yourself (DIY) wood flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

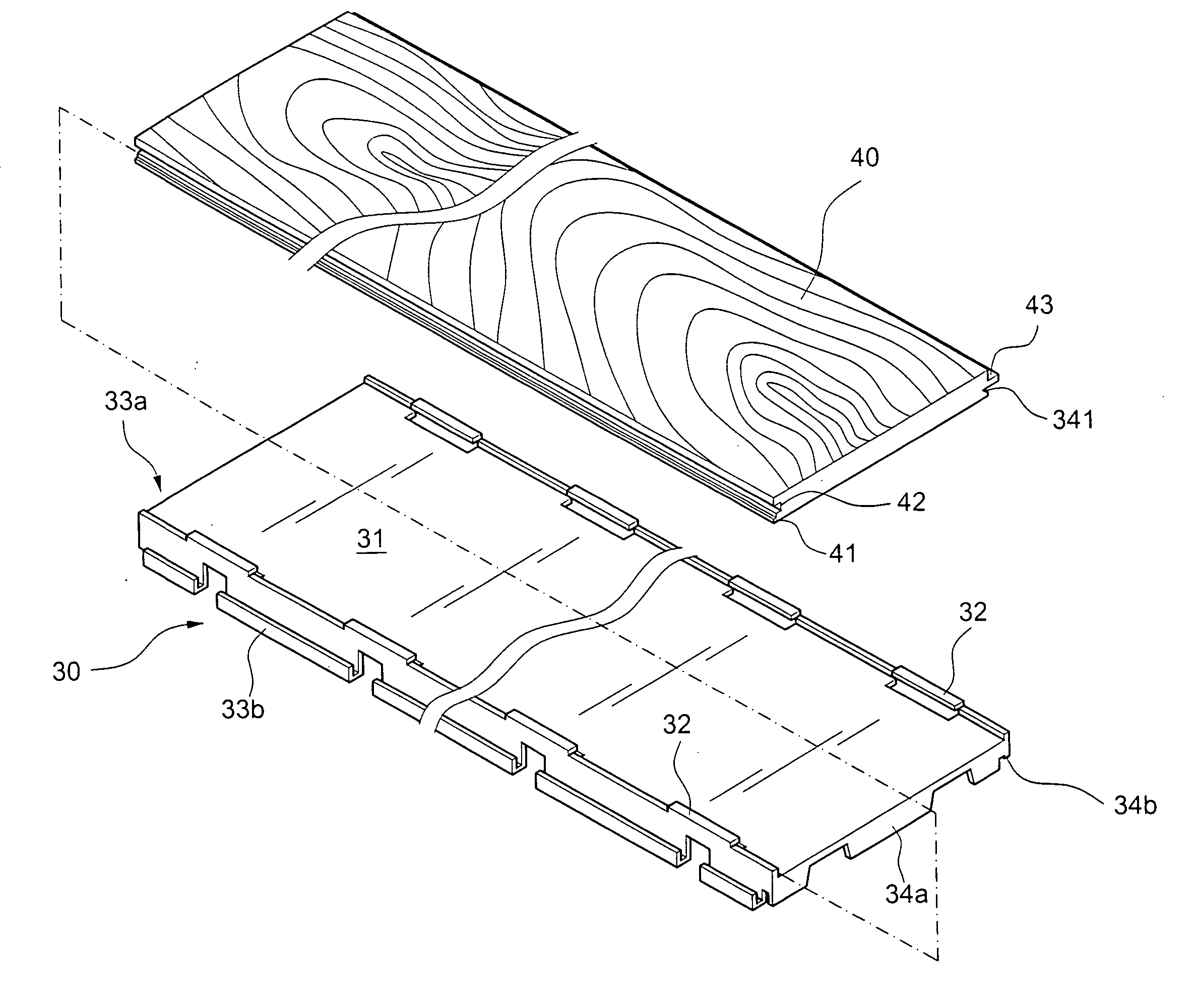

[0023] First of all, referring to FIGS. 3 through 5, the invention includes a plastic base 30 and a solid wood panel 40.

[0024] The plastic base 30 is constructed as an elongated body and made of polypropylene (PP), polyethylene (PE), or acrylonitrile butadiene styrene (ABS) by an injection molding process. The plastic base 30 includes a plurality of built-in hooks 32 facing each other on both of the longer sides of an upper surface 31 thereof. A first female portion 33a and a second female portion 33b are disposed on two certain side edges adjacent to each other. A first and a second male portion 34a and 34b are located at the other two adjacent sides of the plastic base 30 for engaging into the corresponding female portions 33a, 33b of another plastic base 30. In addition, as shown in FIG. 5, the bottom of the plastic base 30 is hollow and provided with a plurality of legs 35. Moreover, at least one transversal groove 36 and longitudinal groove 37 are formed at the bottom of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com