Refrigerating device and refrigerator

a refrigerating device and refrigerator technology, applied in refrigerators/freezers, domestic cooling devices, lighting and heating devices, etc., can solve the problems of unstable refrigerant in a refrigeration cycle, increased power consumption and refrigerating device operation noise, and inability to condense refrigerant in the radiator, etc., to achieve efficient refrigerant recovery operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

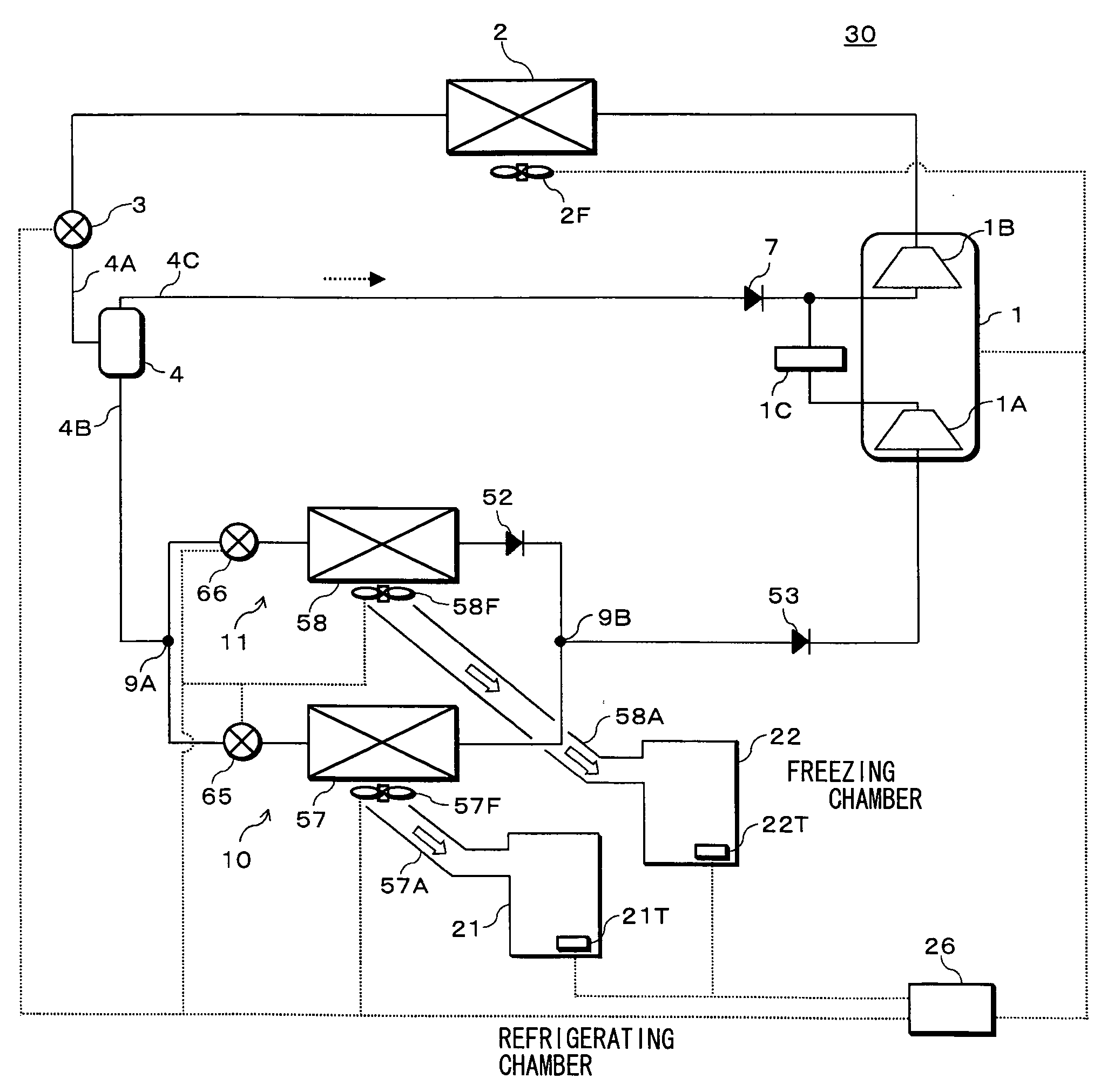

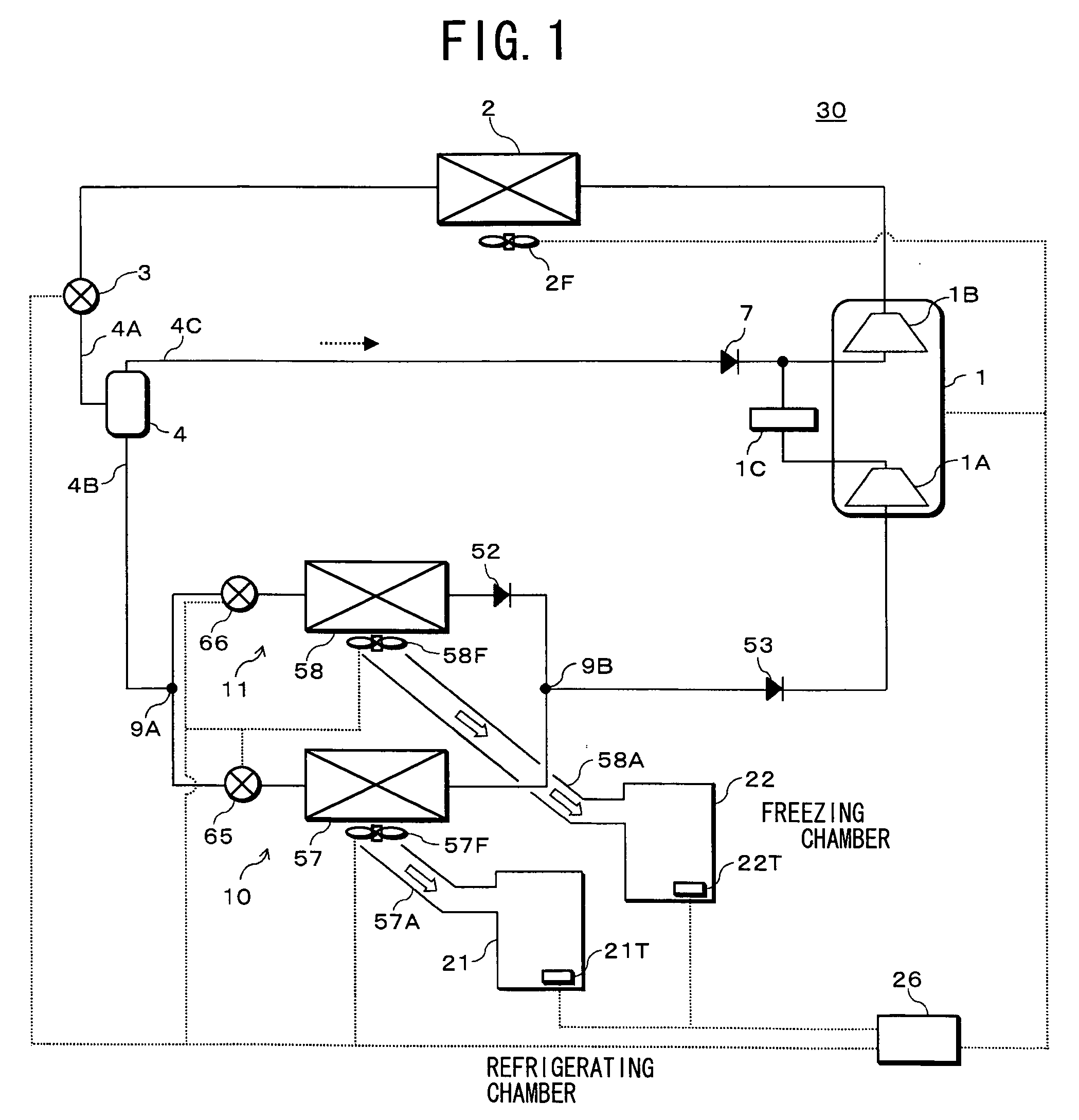

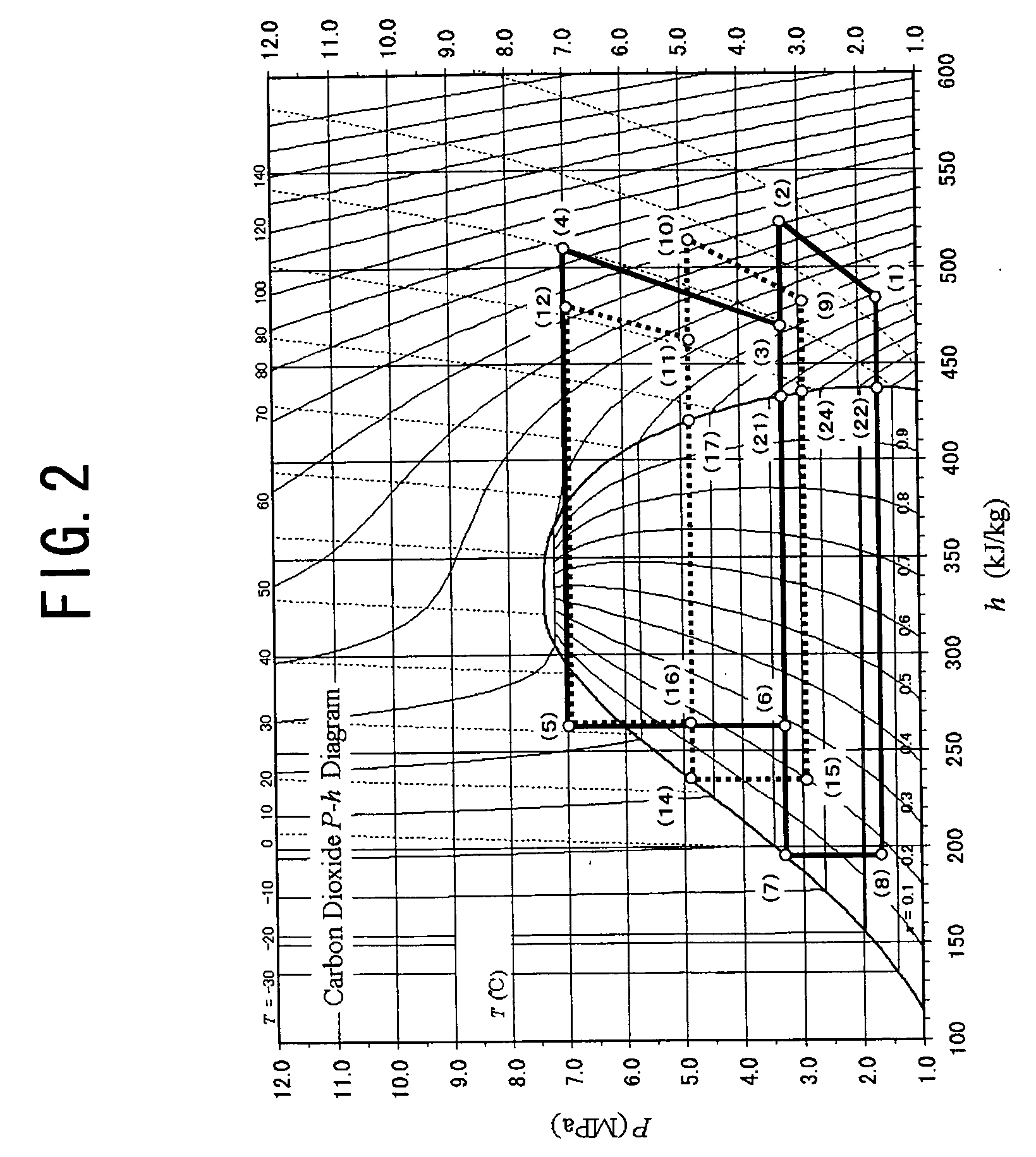

[0027] One embodiment of the present invention will be described in detail with reference to the drawings. FIG. 1 shows a refrigerant circuit diagram of a refrigerating device in one embodiment of the present invention. A refrigerating device 30 includes: a compressor 1; a radiator 2 connected to a discharge side of the compressor 1; a fan 2F which is disposed close to this radiator 2 and which cools a refrigerant in the radiator 2; an expansion valve 3 as pressure reducing means connected to an outlet side of the radiator 2; a gas-liquid separator 4 connected to a refrigerant pipe 4A on an outlet side of this expansion valve 3; a refrigerant pipe 4B in which a liquid refrigerant separated from this gas-liquid separator 4 circulates; first heat absorbing means 10 connected to one side from a branch point 9A from which this refrigerant pipe 4B is branched; and second heat absorbing means 11 connected to the other side from the branch point, disposed in parallel with the first heat ab...

embodiment 2

[0073] Next, another embodiment of the present invention will be described with reference to FIG. 7. FIG. 7 shows a refrigerant circuit diagram of a refrigerating device 50 in this case. In the present embodiment, components denoted with the same reference numerals of Embodiment 1 have identical or similar functions or effects. The present embodiment is different from Embodiment 1 in that third heat absorbing means 10B is disposed instead of the first heat absorbing means 10, and fourth heat absorbing means 11B is disposed instead of the second heat absorbing means 11.

[0074] The third heat absorbing means 10B includes a refrigerant circulation control valve 93, a capillary tube 12, and a heat sink 57. The fourth heat absorbing means 11B includes a refrigerant circulation control valve 94, a capillary tube 13 having a resistance value larger than that of the capillary tube 12, and a heat sink 58. That is, the third and fourth heat absorbing means 10B, 11B include the refrigerant cir...

embodiment 3

[0078] Next, another embodiment of the present invention will be described with reference to FIG. 8. FIG. 8 shows a refrigerant circuit diagram of a refrigerating device 70 in this case. In the present embodiment, components denoted with the same reference numerals of the above embodiments have identical or similar functions or effects. The present embodiment is different from Embodiment 1 in that the refrigerating device includes a three-way valve 91 as refrigerant channel switching means, fifth heat absorbing means 10C instead of the first heat absorbing means 10, and sixth heat absorbing means 11C instead of the second heat absorbing means 11.

[0079] The fifth heat absorbing means 10C includes a capillary tube 12 and a heat sink 57. The sixth heat absorbing means 11C includes a capillary tube 13 having a resistance value larger than that of the capillary tube 12, and a heat sink 58. That is, the fifth and sixth heat absorbing means 10C, 11C include the capillary tubes 12, 13 inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com