Online measurement of molten phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

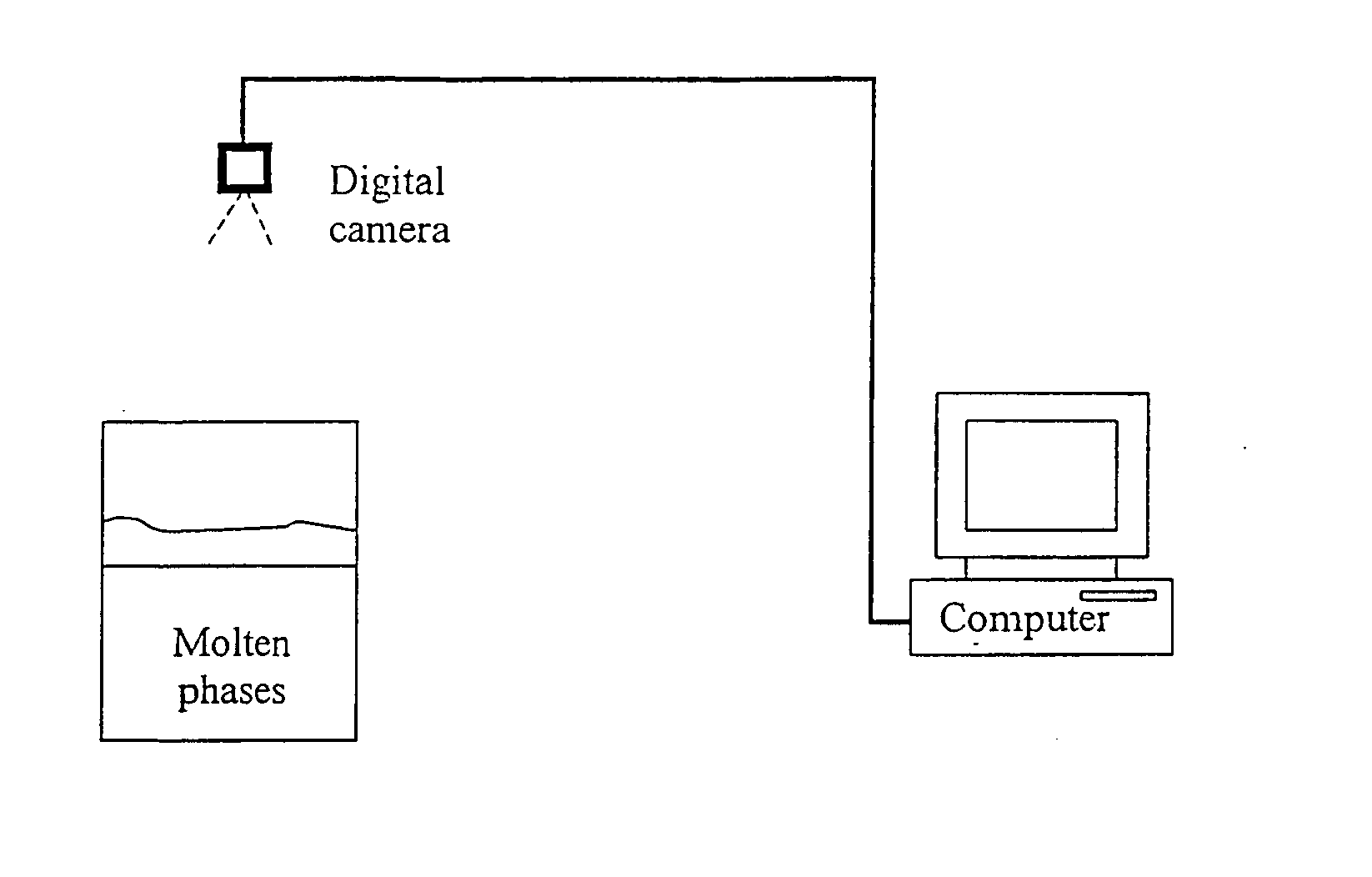

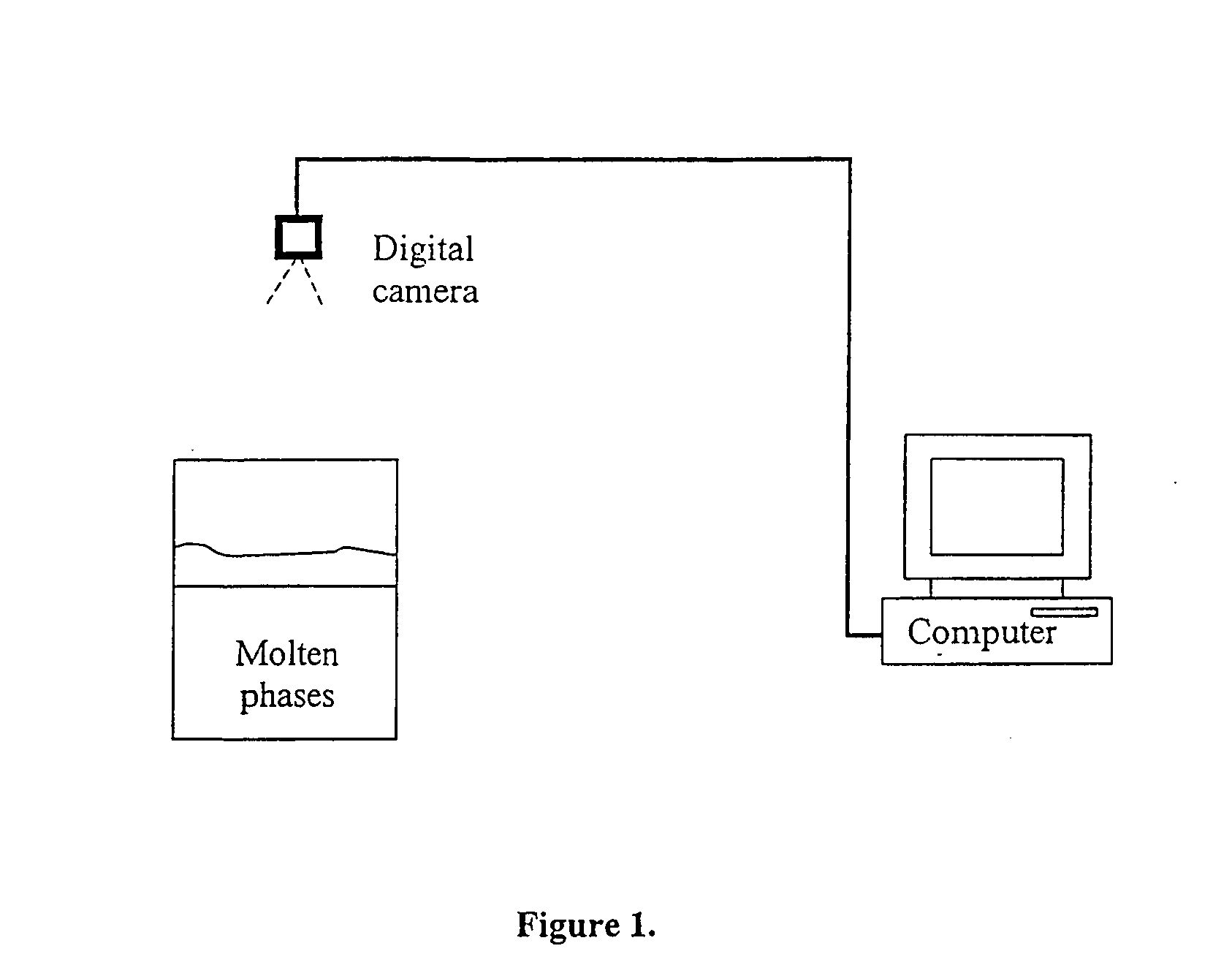

[0012] A schematic depiction of an online measurement system of molten phases is generally indicated by reference numeral 20 in FIG. 1. As shown in the figure, this system 20 is applied to measuring molten phases in a vessel 22 and includes a digital camera 24 for taking image data, and a computer 26 for processing the image data.

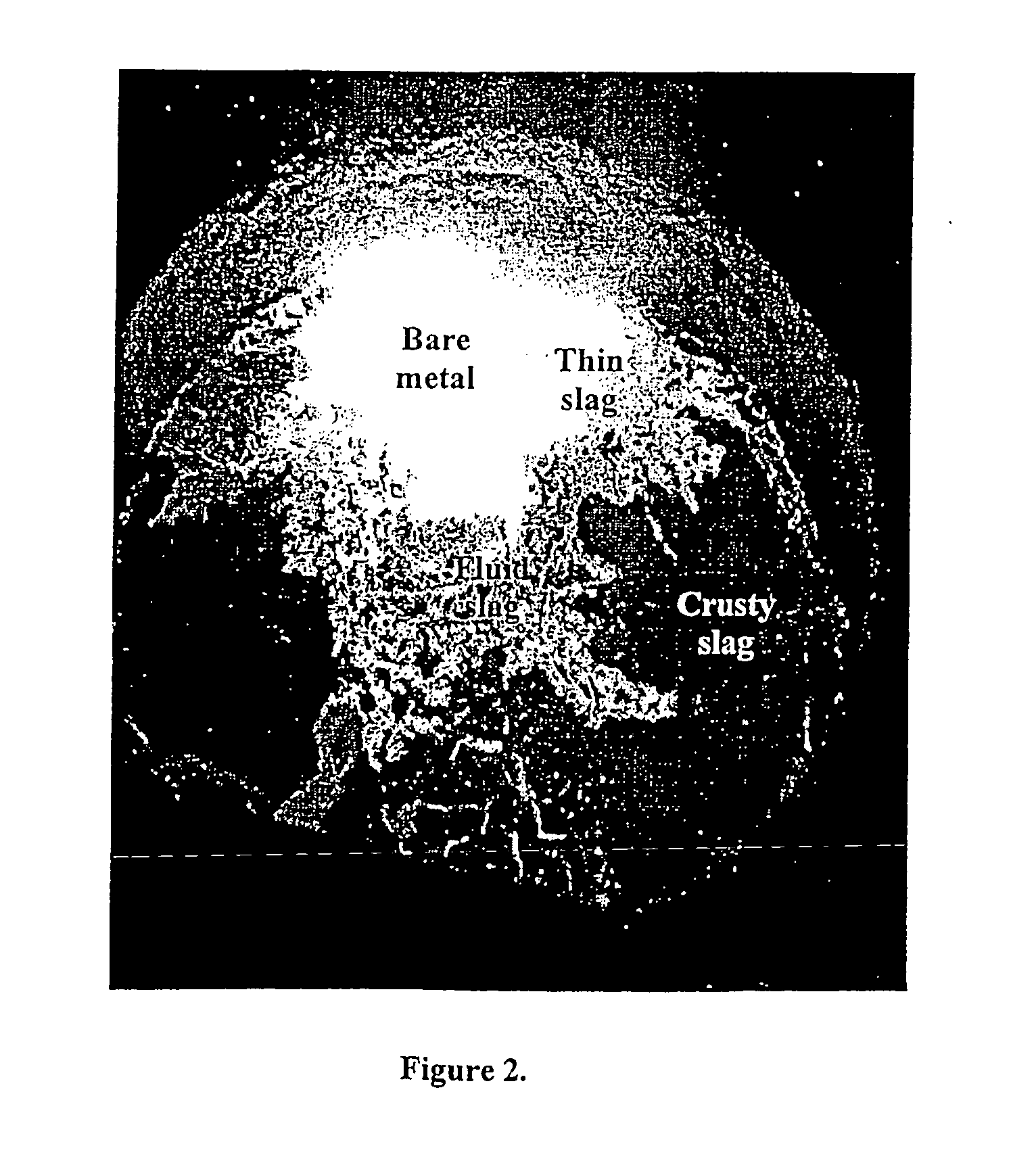

[0013] The very first step for measuring the properties of molten phases, such as disruption of a slag surface, partial solidification of a slag phase, or temperature of the slag, is capturing image data of the slag surface using the digital camera 24 in RGB (Red-Green-Blue) format. The RGB format is a common way to represent high-resolution colour images, which each pixel is specified by three values—one each for the red, green, and blue (RGB) components of the pixel's colour. In a colour image of FIG. 2, the white areas of the image correspond to bare metal, yellow areas correspond to thin slag, brown areas correspond to fluid slag, and black areas corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com