Apparatus for delivering a tool into a submerged bore

a technology of submerged bores and apparatus, which is applied in the direction of well accessories, borehole/well accessories, nuclear elements, etc., can solve the problems of difficult positioning, difficult manual manipulation of these poles and funnels, and the likely only partial inspection of inspections, so as to reduce the outage time of nuclear reactors and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is merely exemplary in nature and is in no way intended to limit the invention, its applications, or uses.

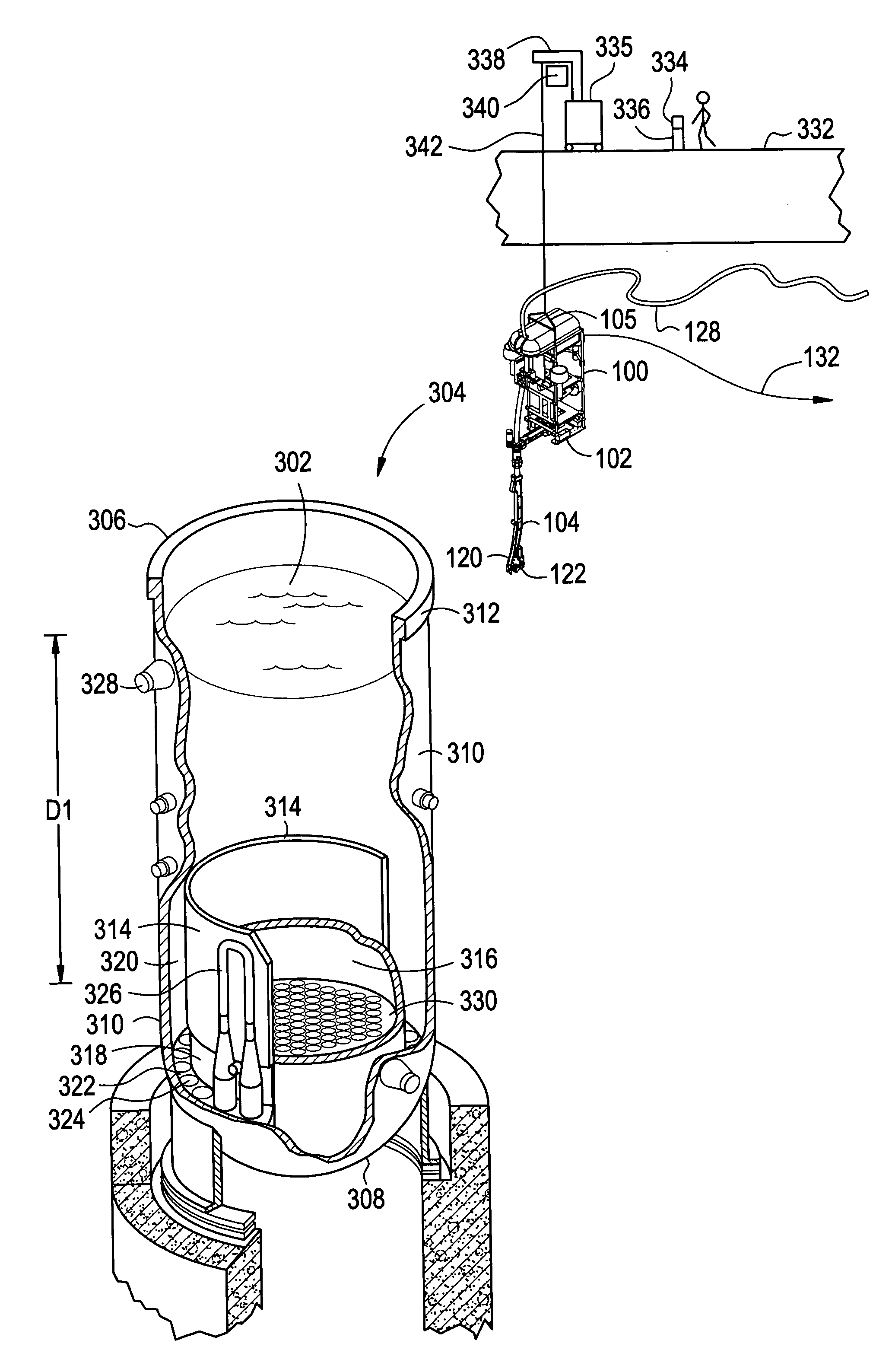

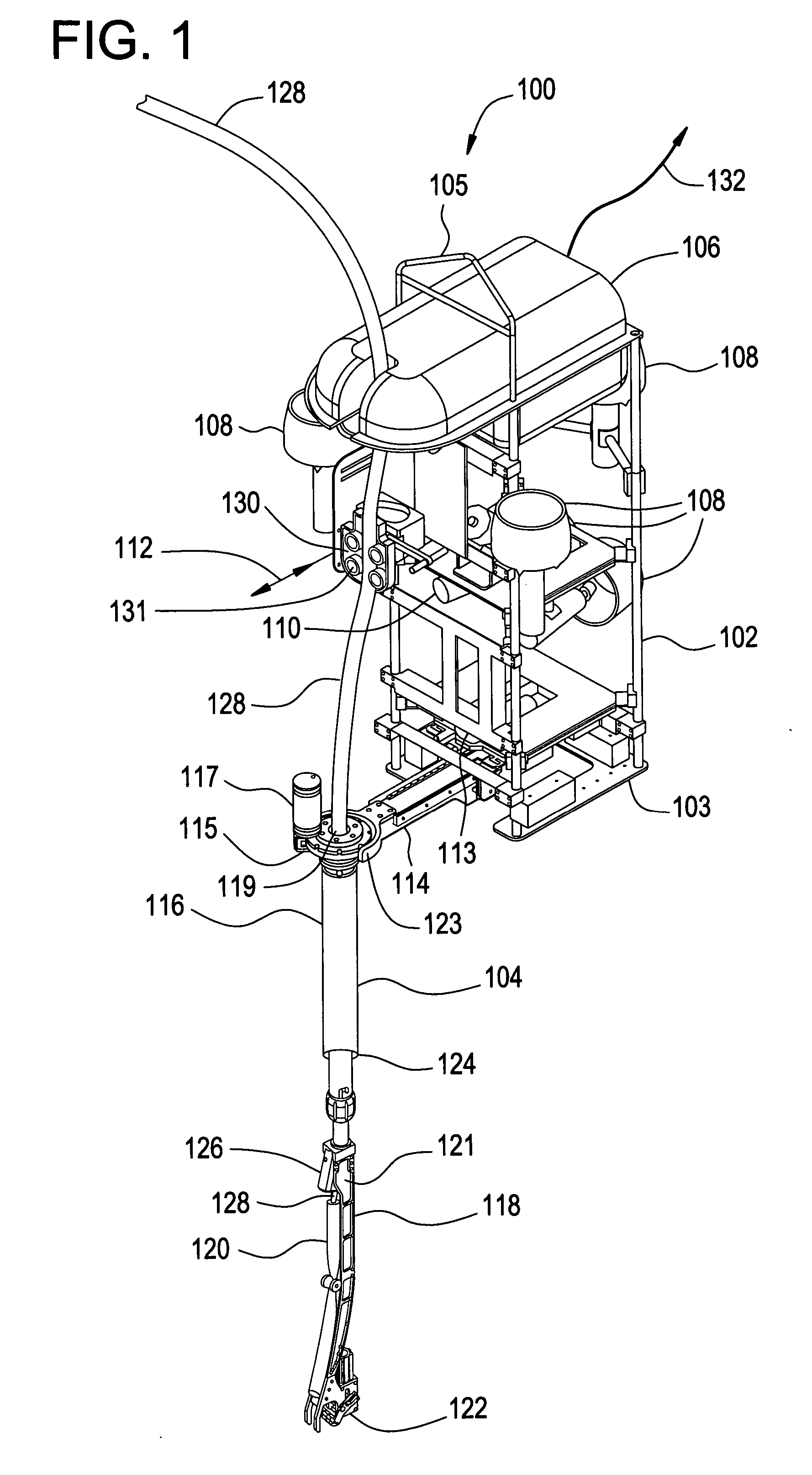

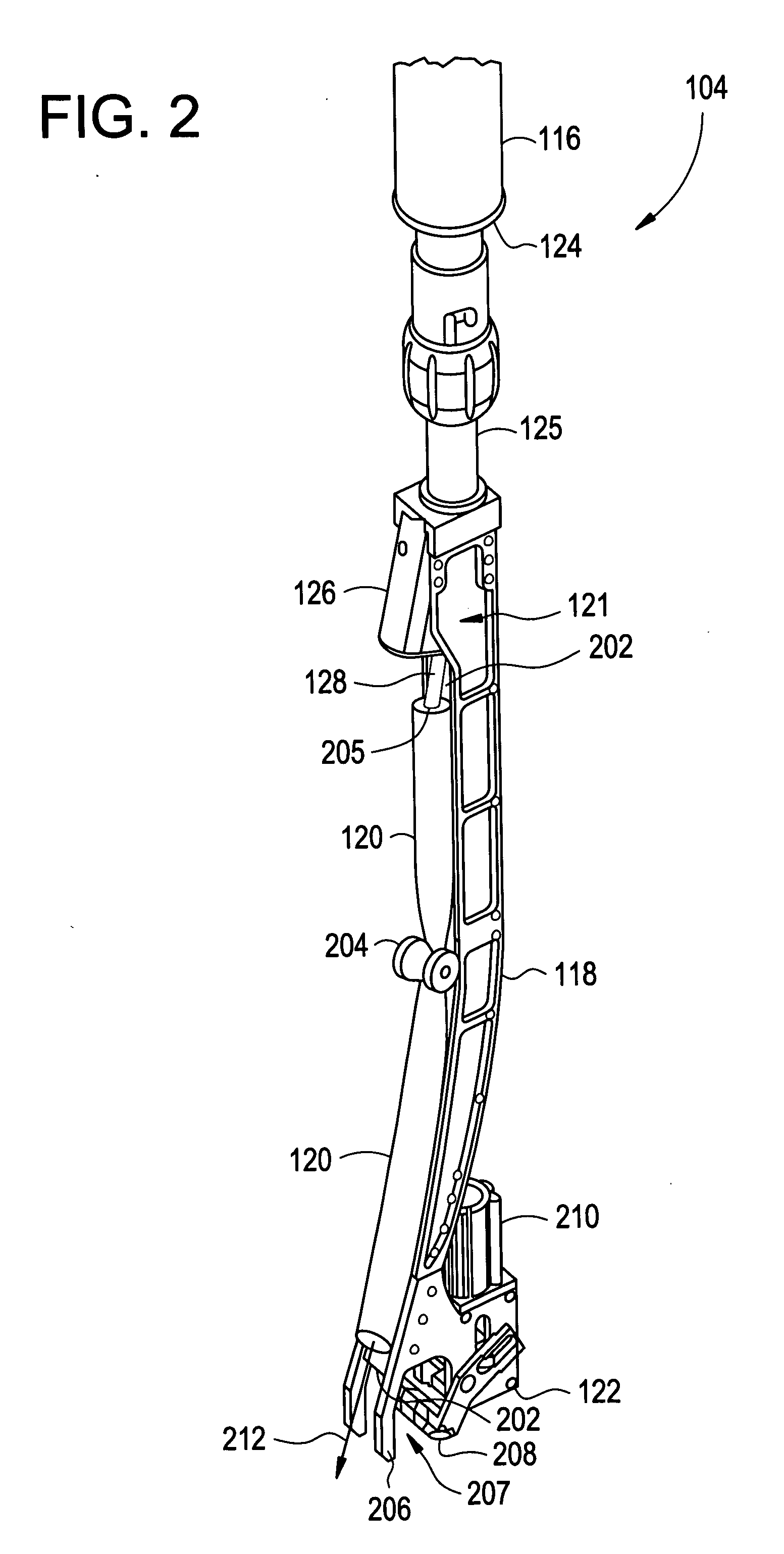

[0021] An inspection delivery assembly, according to various embodiments of the invention, includes a frame, and a propulsion unit for controlling the movement of the tool delivery apparatus within a pool of liquid. A guide assembly provides for delivery and insertion of the tool into an inlet of the jet pump and includes a bore insertion portion. A tool position driver provides for controlling the vertical position of the tool in relation to the guide assembly.

[0022] Referring to FIG. 1, one exemplary embodiment of an inspection tool delivery assembly 100 according to the invention is illustrated. In FIG. 1, the tool delivery assembly 100 includes a submarine assembly 102 and a guide assembly 104. The submarine assembly 102 includes a structural frame 103 for supporting the various components of the submarine assembly 102 and can take any form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com